Rock crack cementing/sealing is important in earth engineering applications, where it is used to inject grout (cementitious materials) into cracks and voids in rocks (located either on the surface or in underground). This process enhances hydraulic properties, provides greater strength, reduces permeability, and improves overall rock stability. Cementitious materials can be used to fill the cracks and openings in rocks to improve their bonding/sealing efficiency, thus enhancing the overall strength of the rock and preventing anti-seepage. Currently, advancements in cementing technologies have introduced innovative methods, which include using nanoparticles, cementitious materials, and chemical cementitious materials, as effective solutions for this purpose. However, because of the limitations of traditional cementitious materials, such as limited resistance to dispersion, inadequate bonding properties, inconsistent mixture design and viscosity, injection pressure, and in-situ stress, an alternative method for in-filling of underground rocks containing cracks and openings is necessary. To address these issues, we developed and proposed a novel nanomagnetic-based cementitious material (which contains nanomagnetic powder, fly ash, and epoxy resin) and used the proposed nanomagnetic-based cementitious materials to fill cracks in rocks, and further assessed if it can seal and improve the strength of the cracked rocks for geo-engineering and underground infrastructure projects. This will inform the civil engineering community if the material has the potential to enhance the hydraulic properties, reduce permeability, and improve the overall mechanical stability of cracked rocks.

The result consists of evidence from flow performance tests, rock density, micro-scale imaging, and strength quantification. The flow performance test revealed distinct variations in the flow rates of the nanomagnetic cementitious material mixtures, highlighting the impact of different proportions of nanomagnetic powder and fly ash. The mixture with 15% nanomagnetic powder (MS1) showed an intermediate flow rate, while the mixture with 35% nanomagnetic powder (MS2) had the lowest flow rate. The mixture with 55% nanomagnetic powder (MS3) achieved the highest flow rate. These results indicate that the flowability of the nanomagnetic cementitious material is influenced by the ratio of nanomagnetic powder to fly ash in the mixture. The study also measured the rock density of both pre-treatment and post-treatment core samples. The results showed an increase in rock density after treatment, suggesting a reduction in void space within the rocks and occlusion of the cracks. This increase in density indicates that the nanomagnetic cementitious material effectively filled and bonded the cracks, creating a denser structure. Scanning Electron Microscopy (SEM) analysis was used to evaluate the microstructure of the rock samples before and after treatment. The SEM images revealed that the untreated rock samples had distinct mineral grains with capillary pore spaces. After cementing, the rock surface was covered with the hardened cementitious material, and the mineral grains were embedded within the cementitious material matrix. This observation suggests that the nanomagnetic cementitious material effectively penetrated and adhered to the crack surfaces, enhancing the bonding strength.

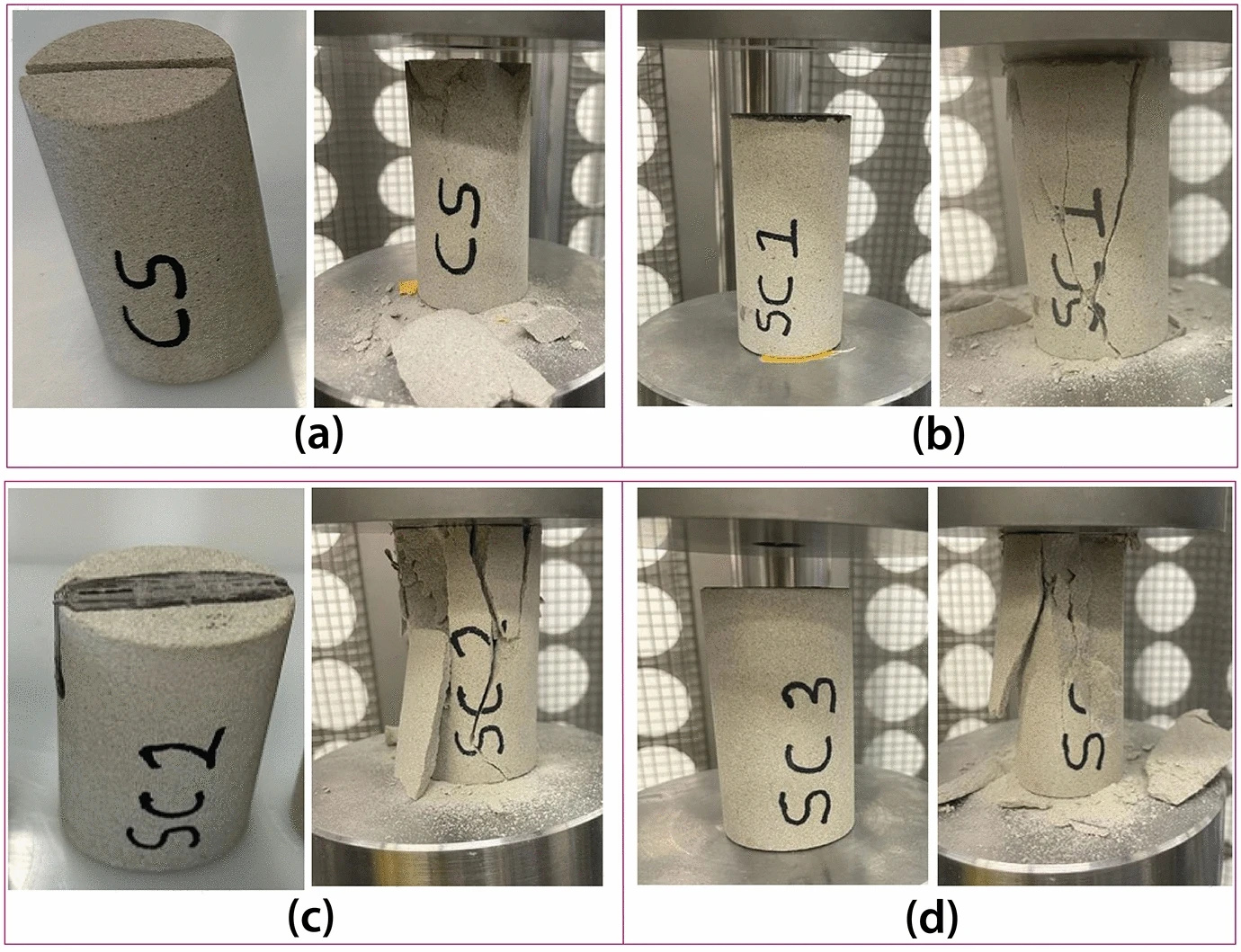

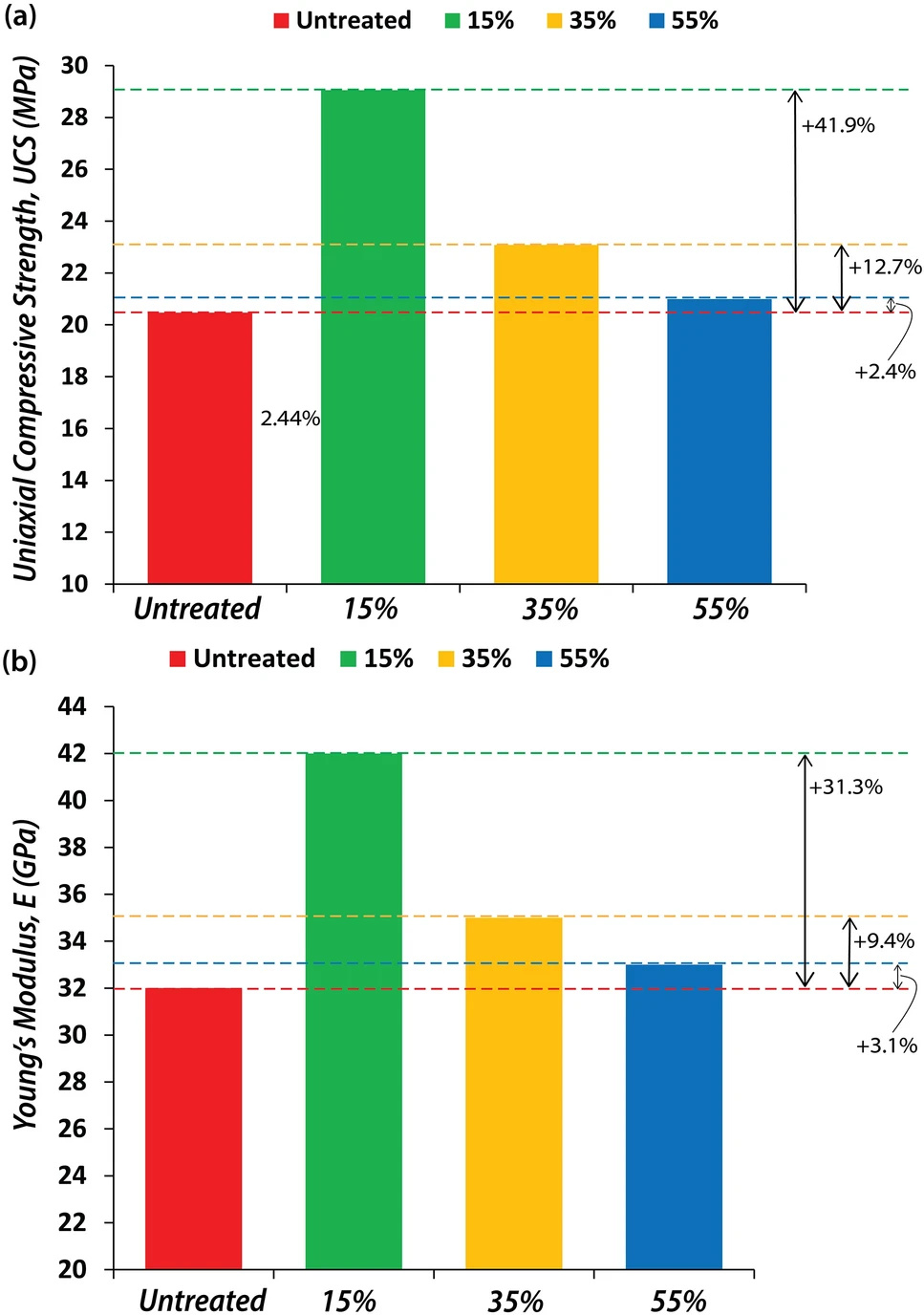

The mechanical properties of the rock samples were assessed using uniaxial compression tests. The results showed that the uniaxial compressive strength (UCS) and Young's modulus (E) of the treated rock samples improved significantly compared to the untreated samples. The mixture with 15% nanomagnetic powder (MS1) yielded the highest strength and stiffness, indicating that this composition provided the most effective reinforcement. The UCS of the treated samples increased by up to 41.9%, and the stiffness improved by up to 31.3%. The study concludes that the nanomagnetic cementitious material is an effective, eco-friendly alternative to traditional cement-based materials. The optimal mixture, containing 15% nanomagnetic material, enhances the rock's density and mechanical properties, making it more resistant to deformation and failure. The nanomagnetic cementitious material offers several advantages, including improved flowability, better bonding strength, and increased durability. Additionally, the use of nanomagnetic materials and fly ash contributes to the sustainability of the cementing process, reducing the environmental impact compared to traditional cement-based slurries.

Overall, the research provides new insights into the development of advanced rock-cementing materials for reinforcing cracked rocks. The findings suggest that the nanomagnetic cementitious material can significantly improve the stability and strength of rock formations, making it a promising solution for geo-engineering and underground infrastructure applications. The study highlights the potential of nanomagnetic cementitious material to enhance the performance of rock-binding operations, offering a sustainable and effective alternative to traditional methods.