Unlocking Strong and Releasable Adhesion through Metamaterial Designs

Published in Materials

Adhesive materials have long been used to create strong bonds between surfaces, but their removal and reusability have often been challenging. Traditional adhesives are either permanent and strong or reversible with limited strength. However, many applications require adhesives that can overcome this trade-off and provide both strong adhesion and easy removal for extended reuse. In this work, we introduce a new class of adhesive materials called “metamaterial adhesives” which offer a promising solution to this paradoxical combination of properties.

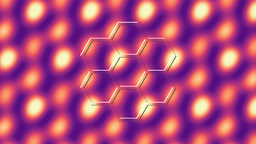

Understanding Metamaterial Adhesives

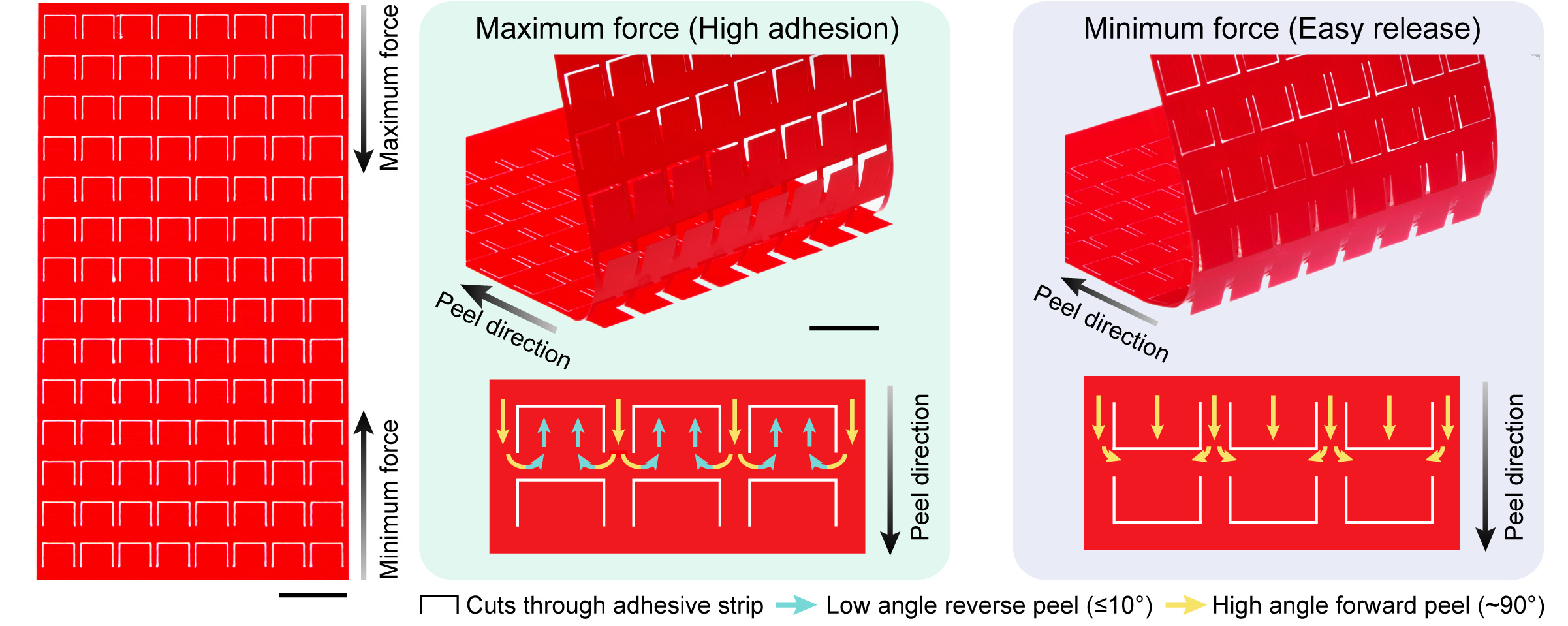

A metamaterial is a structurally engineered material that offers properties beyond those found in naturally existing traditional materials. Our metamaterial adhesives are specifically designed to provide strong and reversible adhesion with directional and spatially selective adhesive strength, a versatile feat that is challenging for traditional adhesives. The metamaterial adhesives are created by incorporating programmed nonlinear cut architectures into conventional adhesive films. These cuts control how cracks propagate across the adhesive sheet, trapping and reversing crack direction for high adhesion in one peel direction, while allowing normal forward propagation for low adhesion in the opposite direction.

The mechanism of reverse crack propagation is key to the enhanced adhesion of metamaterial adhesives. As cracks propagate forward through the unpatterned region past a preceding row of a patterned region, they accelerate and pass through the interconnects, eventually being arrested at the base of the cut. When further loading is applied, the crack propagation direction is reversed, causing the crack to propagate backwards into the adhered rectangular regions at low peel angles. This unique behavior significantly enhances the adhesion up to 60x compared to the same material without cut architectures. The size and design of the cuts play a crucial role in optimizing adhesion enhancement, and the performance of metamaterial adhesives can be customized by modifying the cut structure based on a material-specific characteristic length, serving as a design parameter to meet the specific requirements of different materials and applications.

Benefits and Applications

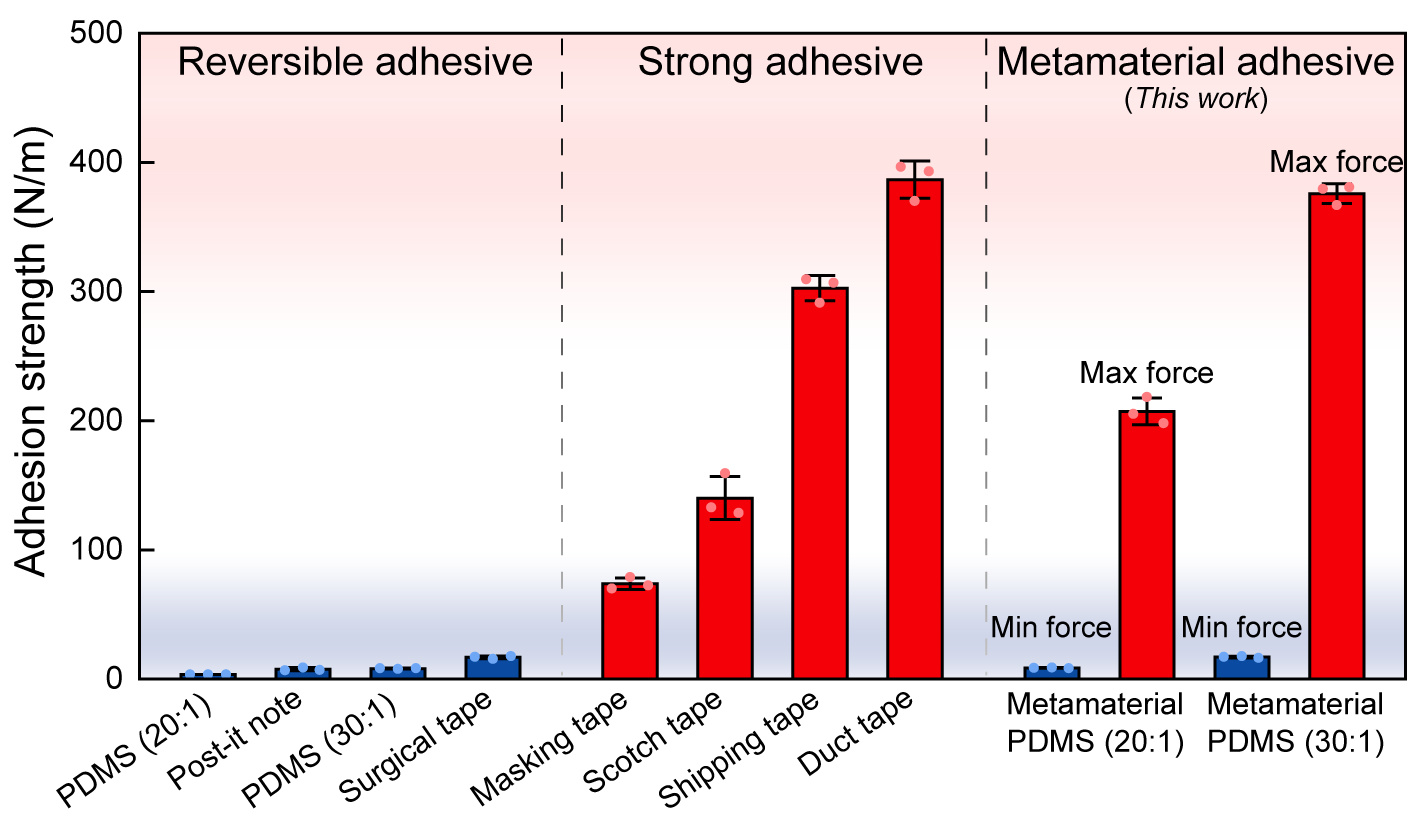

Metamaterial adhesives offer several advantages over traditional adhesives. They achieve a high level of adhesion comparable to strong adhesives like duct tape while providing easy release and reusability similar to Post-it Notes. The adhesion strength and its directionality can also be precisely controlled across the adhesive film, enabling selective strength in multiple specific regions simultaneously.

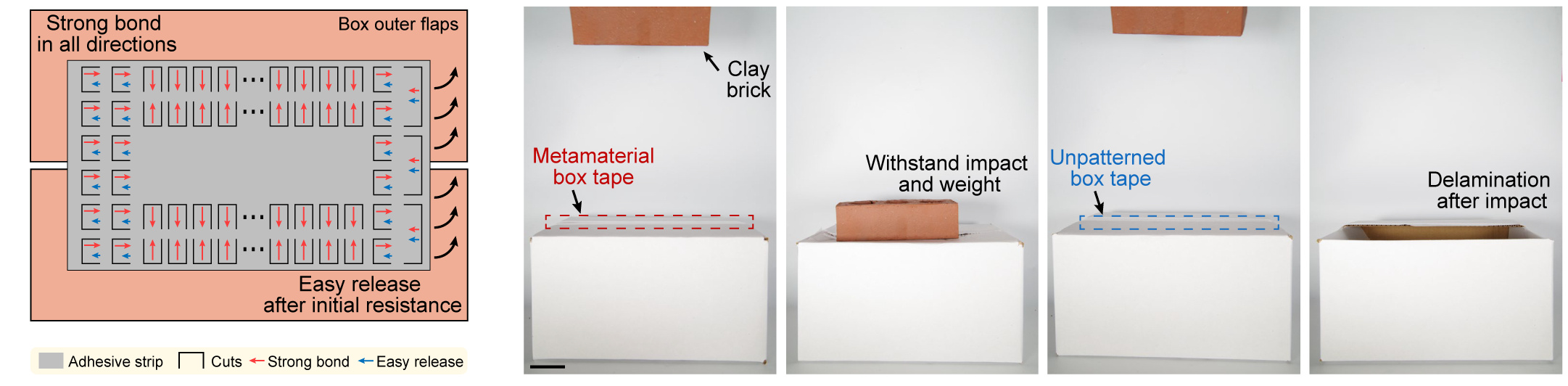

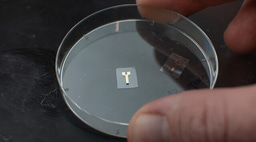

One demonstration of their capabilities involved dropping a 1.5 kg brick onto the flaps of a shipping box sealed with metamaterial adhesive tape. Despite enduring the force of impact during five consecutive drops, the adhesive remained securely adhered, surpassing conventional expectations. It was only after two drops using commercial shipping tape that the box completely collapsed. This striking display showcased the adhesive's ability to withstand extreme conditions while maintaining its gripping power.

The versatility of metamaterial adhesives makes them suitable for various applications, including robotics for locomotion and grasping, wearable electronics for secure attachment and effortless removal of devices used for health monitoring, as well as manufacturing processes that require assembly and disassembly to minimize waste, repurpose materials, and facilitate recycling. They can be effectively utilized on diverse materials, surfaces, and environments. They can be used underwater and on different substrates, including glass, plastic, aluminum, steel, and Teflon. The adhesion performance of metamaterial adhesives surpasses that of other reversible or strong adhesives, combining adhesion enhancement, directionality, and strength in a single material.

Digital Fabrication and Design

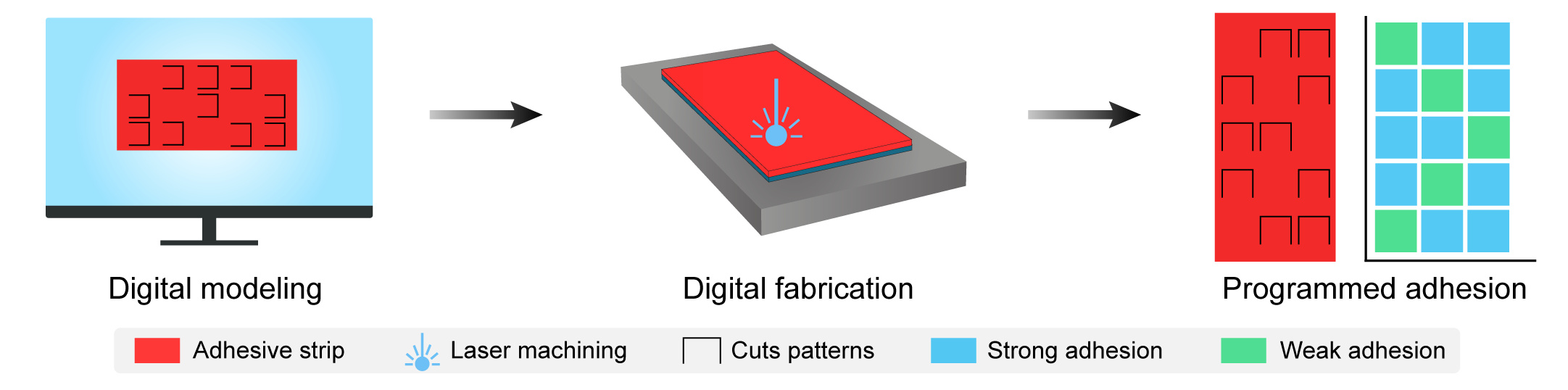

Metamaterial adhesives are manufactured using a digital fabrication approach. Computer-aided design (CAD) is used to create the cut patterns, which are then rapidly patterned in an adhesive film using laser cutting technology. This digital manufacturing process allows for precise control over the adhesive characteristics at any location across the film. In a matter of minutes, metamaterial adhesives can be swiftly designed and fabricated by imprinting desired adhesion profiles onto off-the-shelf adhesive films that typically exhibit uniform adhesive strength.

Conclusion

Metamaterial adhesives represent a leap forward in adhesive technology, breaking the barriers between strong adhesion and easy removal. Using nonlinear cut architectures, these adhesives deliver enhanced adhesion, precise directionality, and reusability, surpassing the limitations of traditional adhesives. With the advent of digital fabrication, we can now automate and customize the design and production of metamaterial adhesives, tailoring them to suit specific needs. The reverse crack propagation mechanism of metamaterial adhesives holds promise for advancements in toughing bulk materials, controlling adhesion in micro/nano systems. In summary, metamaterial adhesives provide exceptional control over adhesion in diverse materials and applications. Their versatility and potential for further development make them a promising avenue for pushing the boundaries of adhesive technology.

For more details, check out our paper “Metamaterial adhesives for programmable adhesion through reversible crack propagation” in Nature Materials.

Follow the Topic

-

Nature Materials

A monthly multi-disciplinary journal that brings together cutting-edge research across the entire spectrum of materials science and engineering, including applied and fundamental aspects of the synthesis/processing, structure/composition, properties and performance of materials.

Please sign in or register for FREE

If you are a registered user on Research Communities by Springer Nature, please sign in