Unlocking the potential of liquid crystal elastomers

Published in Materials

Lack of local phase control technology has hindered active utilization of liquid crystal elastomers in a wide range of fields. Unveiling a novel laser-induced dynamic crosslinking method that enables local phase patterning with three distinct phases, we unleash the full potential of liquid crystal elastomers.

Liquid crystal elastomers (LCEs) have the combined characteristics of liquid crystals and elastic materials, exhibiting molecular realignment in response to external stimuli alongside resilience to substantial deformations. This dual nature empowers LCEs with a wide array of mechanical and optical properties, rendering them invaluable in applications such as actuators, soft robotics, sensors, optical devices, and shock mitigation systems. Consequently, LCEs have garnered considerable attention as a highly promising material with multifaceted potential.

The mechanical and optical properties of LCEs are intricately linked to their molecular alignment, which dictates their phase classification—polydomain, monodomain, or isotropic. Each phase manifests distinct properties, with transitions between them enabling reversible alterations in mechanical shape and optical characteristics. For instance, the transition from a polydomain to an isotropic phase renders LCEs transparent, while the monodomain-isotropic transition facilitates shape modification through thermal cycling.

While recent advancements, including 3D printing technologies, have enabled control over molecular alignment, substantial limitations persist. Presently, most research efforts primarily address the monodomain-isotropic phase transition, overlooking strategies to harness the full spectrum of phases. Furthermore, once set in a specific phase, LCEs typically cannot be reconfigured to another phase, constraining their applicability.

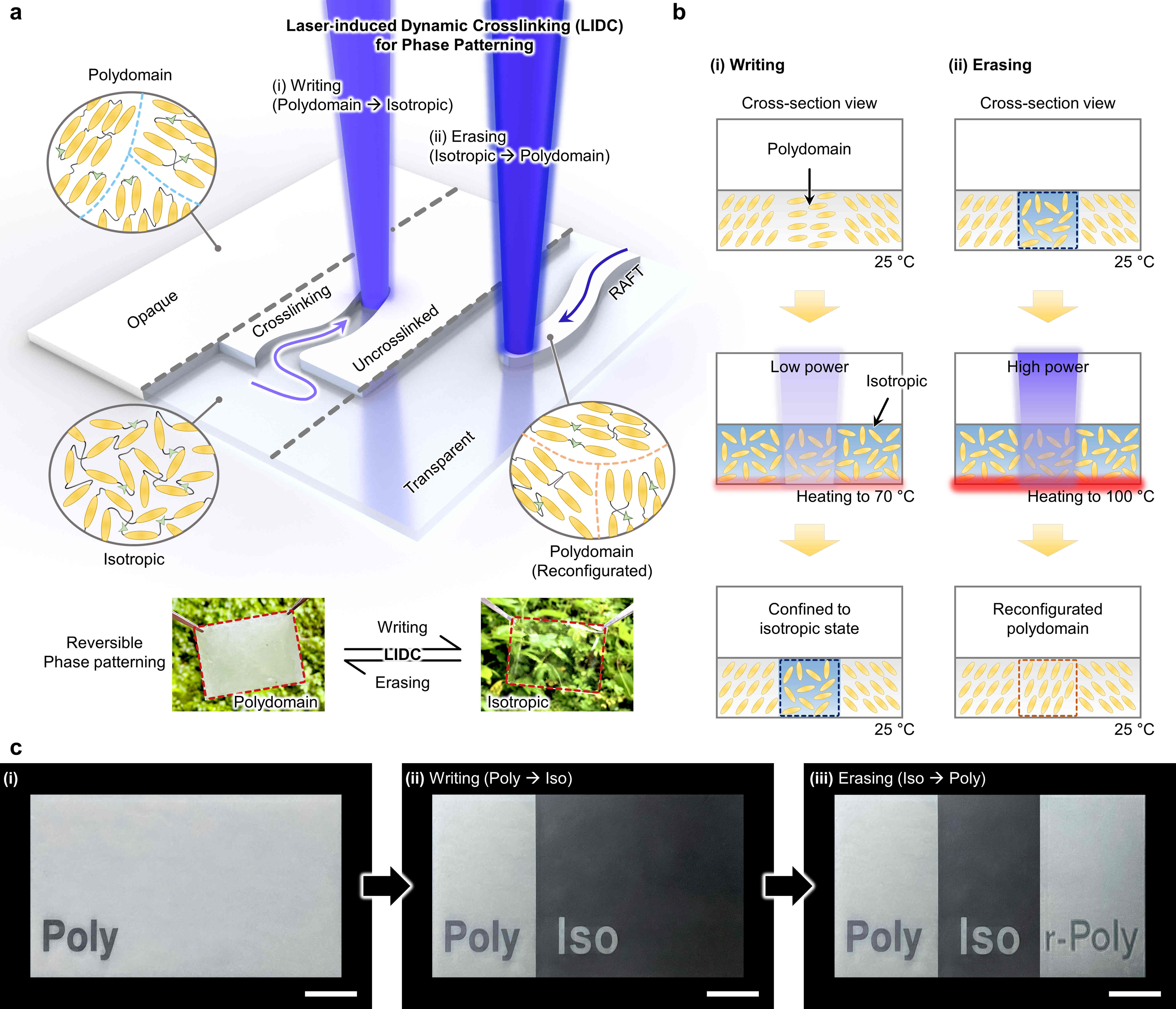

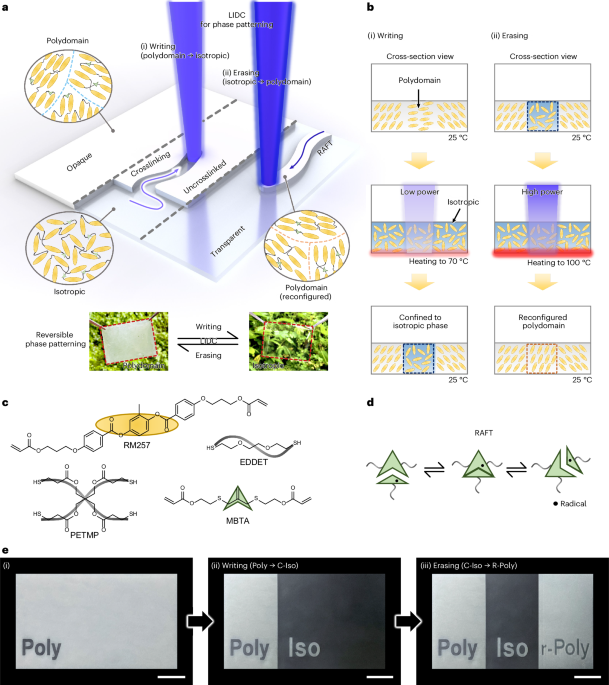

Based on this motivation, our research team has devised a novel methodology for controlling the phase of LCEs, as delineated in a recent publication in Nature Materials. This innovative approach, named laser-induced dynamic crosslinking (LIDC), enables reversible phase patterning through the precise application of a UV laser coupled with dynamic crosslinking mechanisms. Notably, LIDC enables the fabrication of isotropic phase LCEs at room temperature, facilitating the production of transparent LCEs without the necessity of thermal stimulation. Furthermore, LIDC offers the unique capability of restoring the produced phase or effecting transitions to alternative phases in a reversible manner, thereby underscoring its potential to revolutionize the versatility and utility of LCEs in various applications.

Figure 1. The LIDC process. a, Schematic illustration of reversible selective phase patterning of LCEs via LIDC. b, Molecular organizations of LCEs during the writing process (i) and the erasing process (ii). c, Monolithically patterned LCE: polydomain (Poly) LCE (left), C-Iso LCE after the writing process (middle) and R-Poly LCE after the erasing process (right). Scale bars, 10 mm.

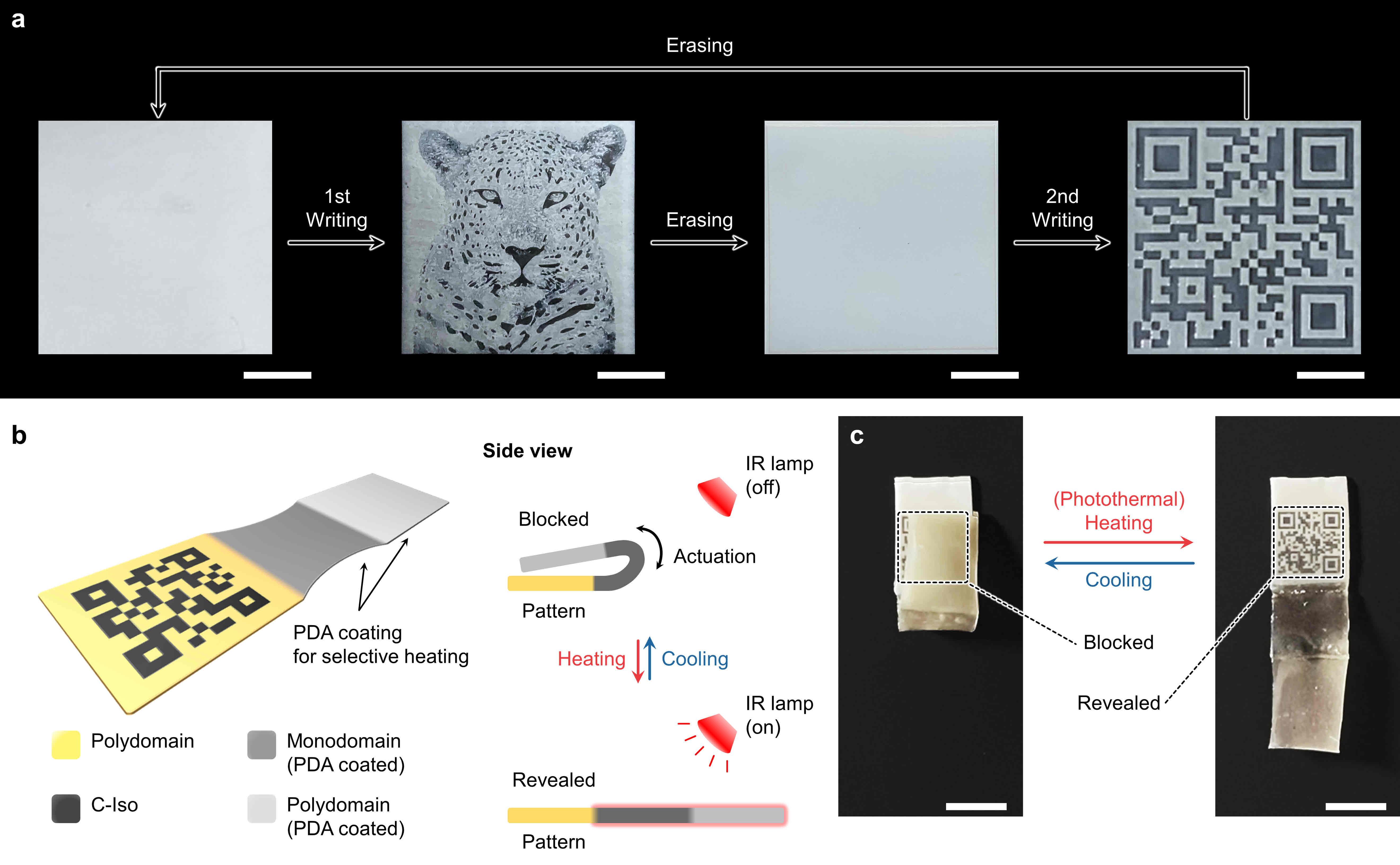

The main principle underlying this technology revolves around the utilization of energy derived from secondary crosslinking to constrain the mobility of reactive mesogens, effectively locking the LCE networks into an isotropic configuration. By introducing an integrated parameter indicative of the energy density employed in crosslinking LCE networks, we have attained precise grayscale phase patterning through parameter adjustments. Leveraging the high resolution and controllability of the laser process, we have demonstrated the capability to achieve intricate patterning with varying degrees of transparency, thereby showcasing the technology's efficacy in generating informational patterns such as QR codes.

The confined network architecture can undergo reprogramming facilitated by the intentional inclusion of a dynamic bond agent, thereby enabling the reusability of LCE films. This strategic introduction of the agent also accompanied the decrease in the transition temperature of the LCEs, which serves to enhance the viability of LCEs in wearable and human-centric applications.

The developed phase patterning technology not only enables the induction of transparency variations by patterning polydomain and isotropic phases but also facilitates motion induction through conventional mechanical methods capable of generating monodomain phases. With the exceptional resolution afforded by this process, the fabrication of millimeter- or micrometer-scale soft robots becomes increasingly feasible. Furthermore, the ability to pattern all three phases enhances the functionality of liquid crystal elastomers across numerous potential applications. These materials are now not only confined to the realms of actuators and soft robotics but have also emerged as powerful display tools capable of representing users' intentions, whether to reveal or conceal information.

Figure 2. Repeatability of LIDC and thermal stimulus-responsive properties of patterned LCEs. a, Images representing the demonstration of the repeatability of LIDC. Scale bars, 10 mm. b, Schematic illustration of LCEs patterned with three phases and selectively coated with polydopamine (PDA) for concurrent utilization of both patterning and actuation. c, Images of the patterned LCE with the pattern blocked (left) and revealed (right) by actuation via photothermal heating. Scale bars, 10 mm.

Considering these advancements, we anticipate that this phase patterning technology will not only expand the functionality of liquid crystal elastomers but also provide researchers and engineers with a versatile tool that empowers them to tailor liquid crystal elastomers to suit diverse needs with unprecedented freedom and precision.

More details on this study can be found in our recent article "Phase patterning of liquid crystal elastomers by laser-induced dynamic crosslinking" published in Nature Materials.

(https://doi.org/10.1038/s41563-024-01845-9)

Follow the Topic

-

Nature Materials

A monthly multi-disciplinary journal that brings together cutting-edge research across the entire spectrum of materials science and engineering, including applied and fundamental aspects of the synthesis/processing, structure/composition, properties and performance of materials.

Please sign in or register for FREE

If you are a registered user on Research Communities by Springer Nature, please sign in