Multifunctional and Biodegradable Self-Propelled Protein Motors

Published in Bioengineering & Biotechnology

In Nature, we find chemical motors all around us, from the molecular scale (myosin contracting our muscles) to the millimeter scale (locomotion of semi-aquatic insects). Some semi-aquatic bugs can move on the water surface by secreting chemicals that reduce the local surface tension behind them and generate a propulsive force, known as Marangoni propulsion. In an effort to replicate these natural motors, different self-propelled chemical motors based on Marangoni propulsive forces have been developed over the years utilizing a diversity of materials and fuels. However, most self-propelled motor systems have significant limitations that constrain their overall performance: low efficiency (high volume of fuel is required for locomotion), short mobility lifetime, lack of control, difficult miniaturization, and toxicity. Such restrictions pose design, performance, control, and sustainability challenges that need to be addressed to expand the applications of such motor systems to real world scenarios.

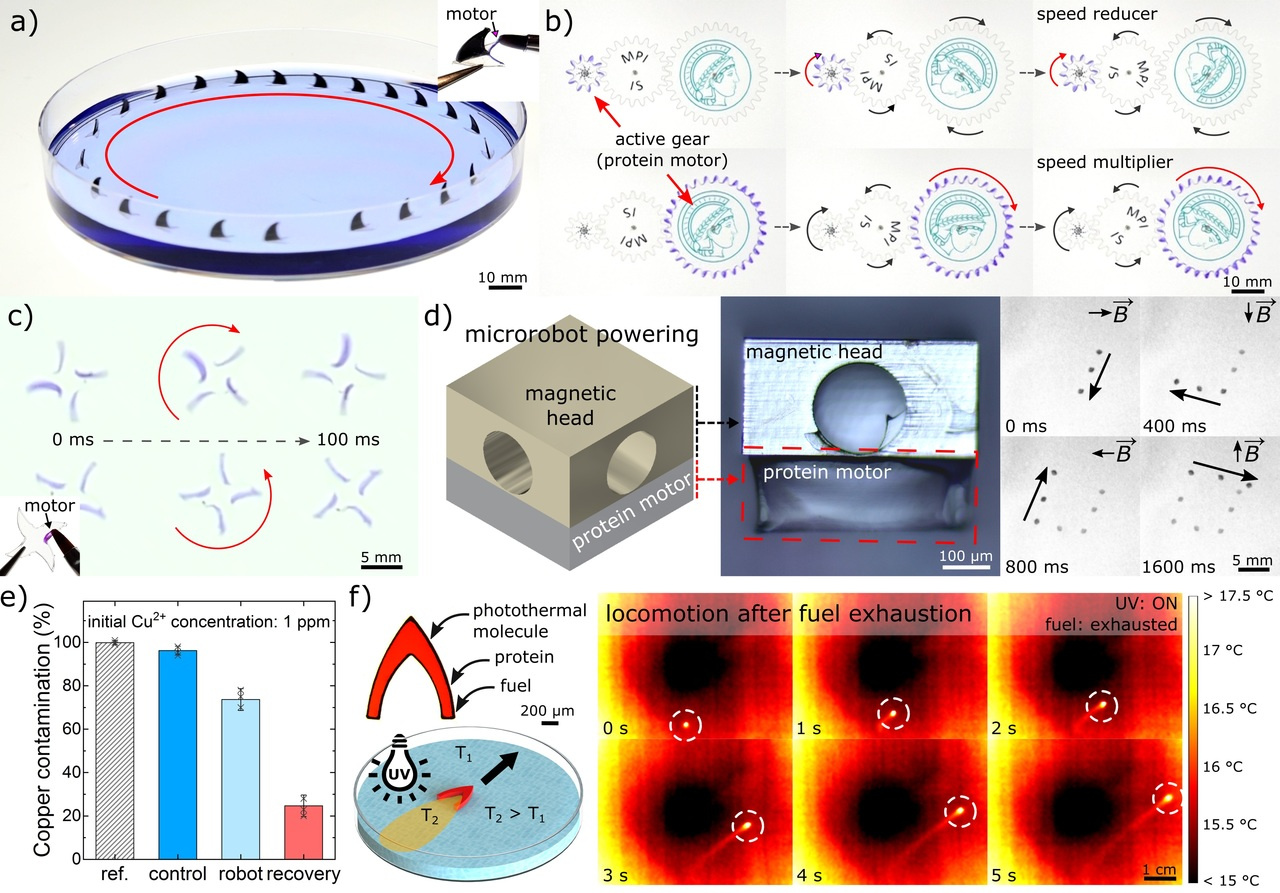

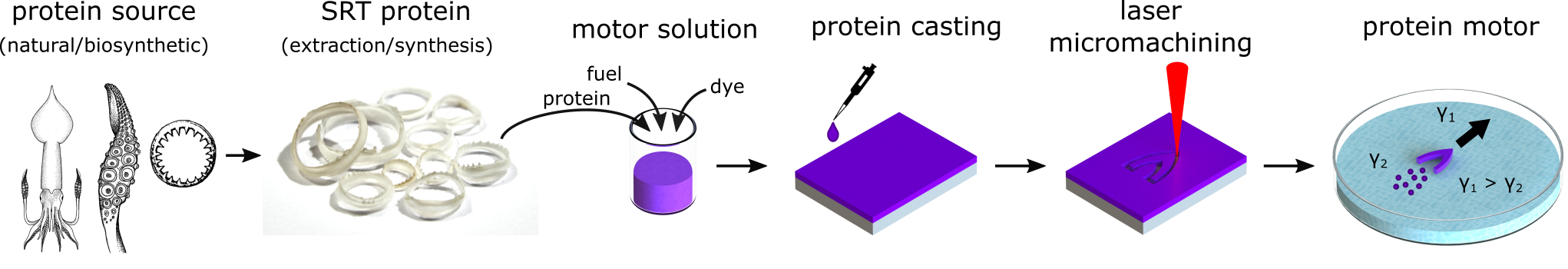

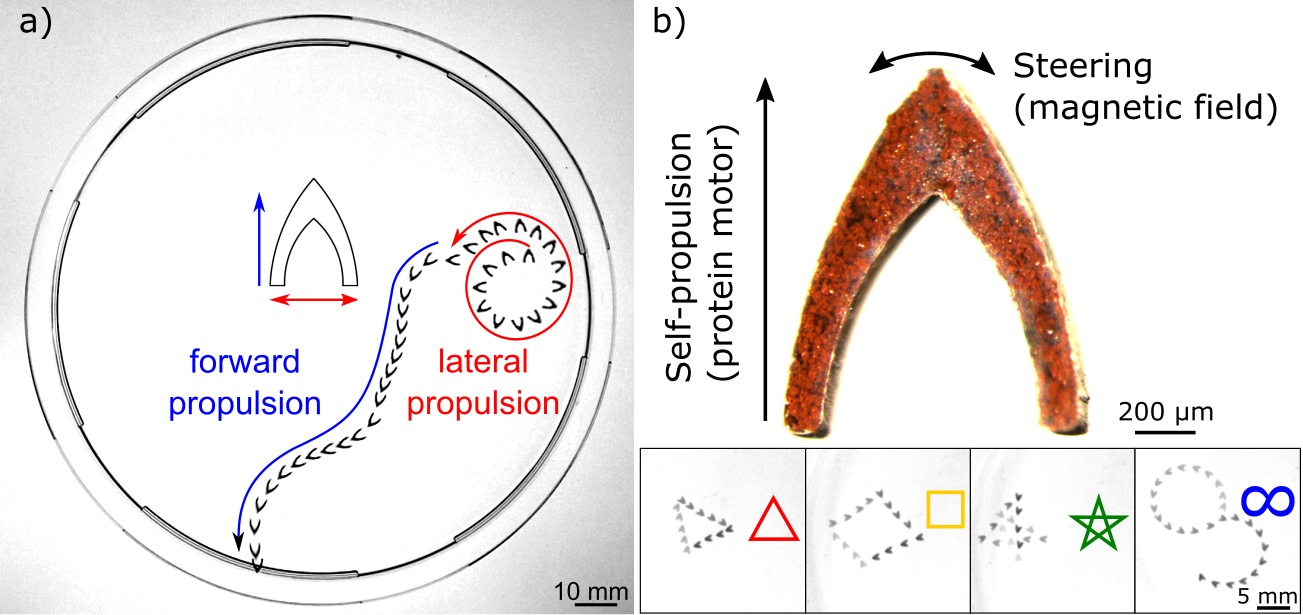

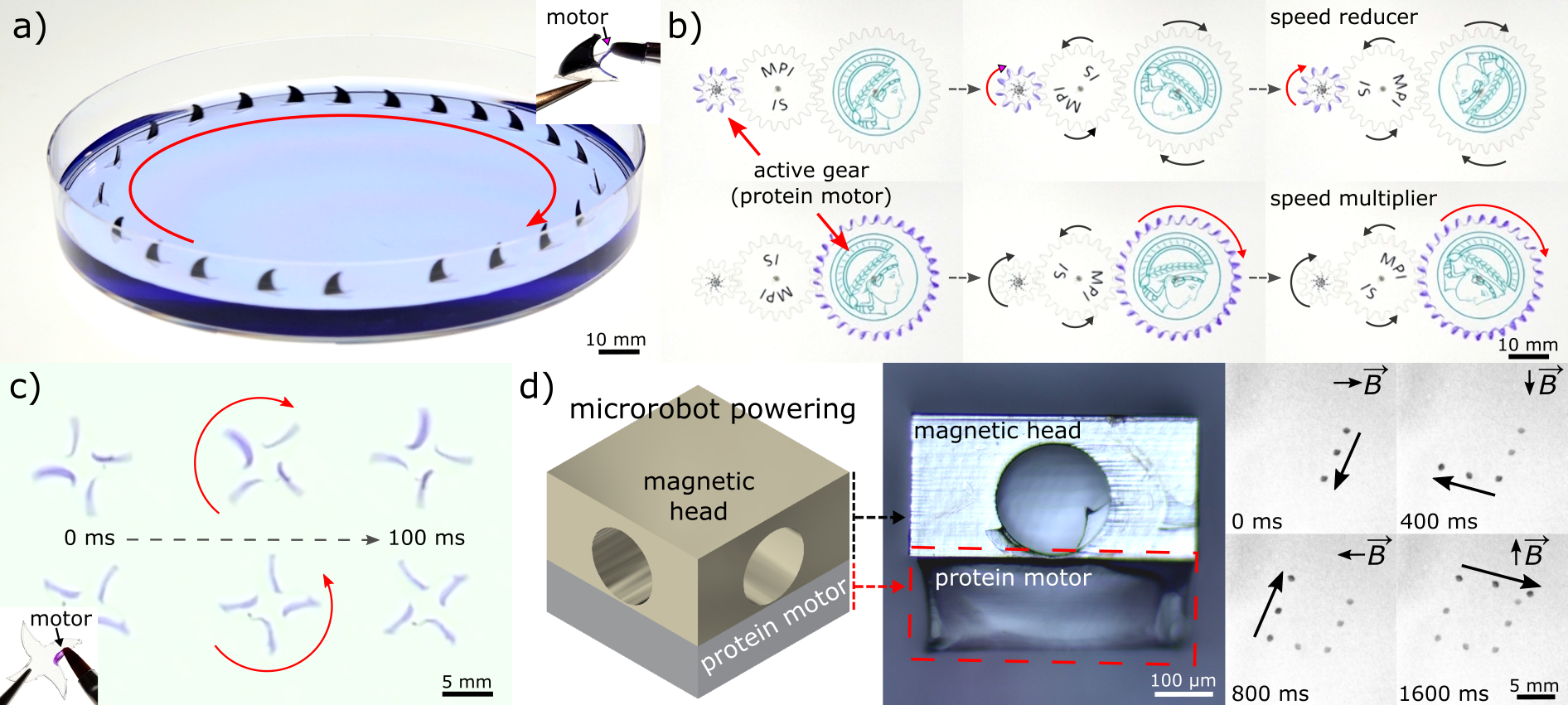

Our research team (Dr. Abdon Pena-Francesch @abdon_pf, Dr. Joshua Giltinan, Prof. Metin Sitti @metin_sitti) from the Max Planck Institute for Intelligent Systems (Stuttgart, Germany) is working on overcoming these limitations by developing new self-propelled motors from biologically derived materials. In our recent publication in Nature Communications, we have developed multifunctional and biodegradable self-propelled motors from cephalopod-derived proteins and an anesthetic metabolite. Due to the tunable nanostructure of the protein materials (β-sheet self-assembled proteins extracted from the suction cups of squids) and the physical/chemical properties of the fuel (a metabolite of a general inhalation anesthetic), our protein-based motors have orders of magnitude higher performance output, efficiency, and mobility lifetime than previously reported Marangoni motors. We optimized the motor design, miniaturized it down to a hundred microns (with speeds up to 400 mm/s), and controlled the locomotion via motor design and magnetic steering (protein magnetic nanocomposites), achieving programmable complex locomotion.

After understanding the propulsion mechanism and optimizing the performance across length scales (speed, efficiency, mobility lifetime, control, etc.), we asked ourselves how we could push our protein motors past current limitations of self-propelled systems:

“Regardless of the performance and efficiency, all motors need fuel to work… What happens when they eventually run out of fuel?”

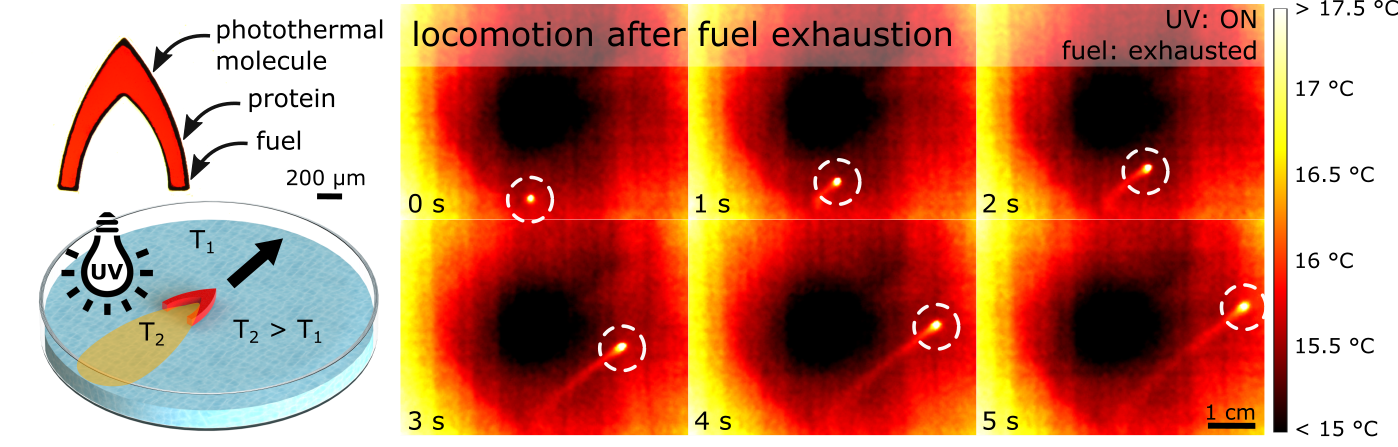

An intrinsic limitation of self-propelled motors is the availability of chemical fuel, since motors have no means of doing work when the fuel is completely exhausted. However, we can induce locomotion to the protein motors after the fuel is exhausted via non-contact photothermal propulsion, giving the motors a second operational lifetime.

“Are the motors toxic to the environment? Are they biocompatible or biodegradable?”

Most synthetic chemical motors present biocompatibility challenges because: i) the motor itself is not biocompatible, ii) the fuel is highly cytotoxic, and iii) the propulsion mechanism requires hazardous chemical reactions in the swimming media. However, our protein motors present a fully biocompatible alternative: i) the protein that constitutes the motor is not only biocompatible but also biodegradable via disruption of the hydrogen bonding network and enzymatic degradation; ii) the fuel is a metabolite of sevoflurane (FDA-approved and widely used inhalation general anesthetic), which can be excreted in urine; iii) hazardous chemicals are not required in the liquid media, thus the protein motors can operate in water and other physiological fluids.

“Ok, the motors perform great. So what?”

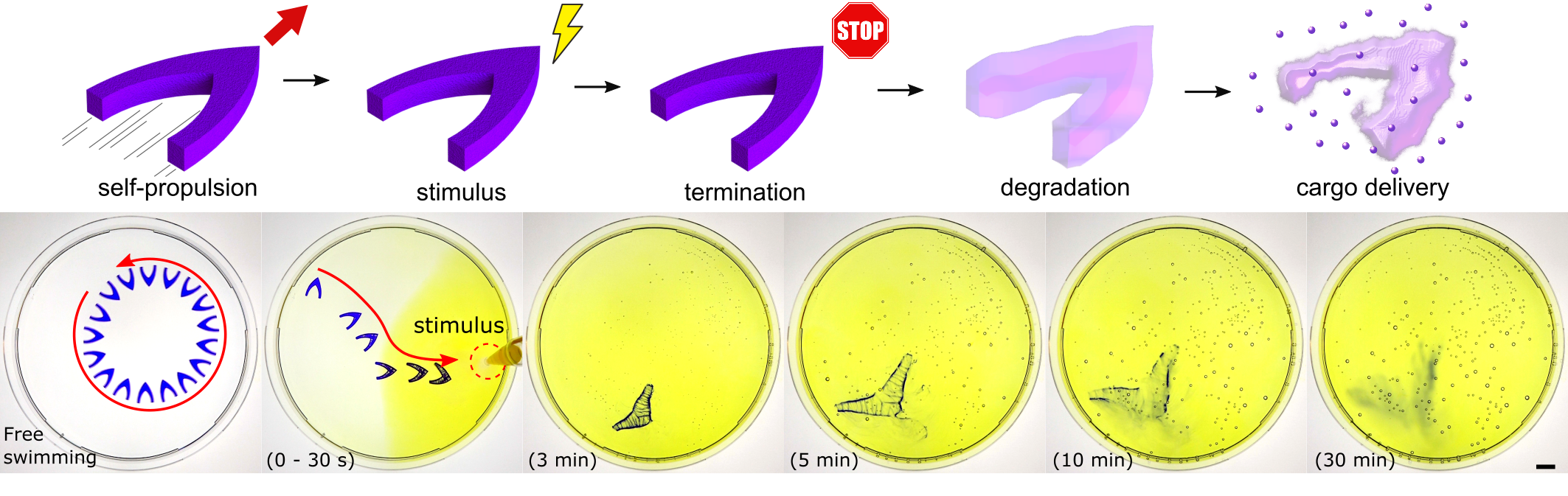

Most previously reported self-propelled motors are non-functional passive elements, solely used for fuel storage, and with little control over the locomotion. To demonstrate their use in diverse applications, we explore multiple functionalities of our protein motors by taking advantage of the programmable protein nanostructure and properties. For example, we demonstrate stimuli-responsive drug release via the self-destruction of the motors for targeted cargo delivery, removal of heavy metal water contaminants for environmental remediation, and modular powering of inanimate objects (such as microrobots and small-scale devices).

These protein motors can be integrated onto virtually any material as a modular propulsion source, and can be functionalized with diverse nanoparticles and biomolecules, opening up the design space for control, sensing, and actuation schemes for small-scale robots, machines, and devices. To our knowledge, this is the first biodegradable self-propelled surface motor that is capable of such multifunctionality, high performance, and precise control at the air-liquid interface. Future work will explore protein motors as modular biodegradable propulsion sources in microrobotics for minimally invasive medical operations in physiological environments with natural or engineered air-liquid interfaces for sensing and therapeutic applications.

For more details, you can find the full paper here: https://www.nature.com/articles/s41467-019-11141-9

Follow the Topic

-

Nature Communications

An open access, multidisciplinary journal dedicated to publishing high-quality research in all areas of the biological, health, physical, chemical and Earth sciences.

Related Collections

With Collections, you can get published faster and increase your visibility.

Women's Health

Publishing Model: Hybrid

Deadline: Ongoing

Advances in neurodegenerative diseases

Publishing Model: Hybrid

Deadline: Mar 24, 2026

Please sign in or register for FREE

If you are a registered user on Research Communities by Springer Nature, please sign in