Paving the Future of Intelligent Asphalt Defect Detection with Machine Learning

Published in Computational Sciences, Civil Engineering, and Mechanical Engineering

Road networks are critical to economic activity and public safety, yet traditional pavement inspection remains largely manual and reactive. Visual surveys are slow, inconsistent, and costly, and many structural failures begin below the surface, invisible to the naked eye. In my survey, I synthesize recent machine-learning advances that enable faster, more objective, and predictive pavement management, providing the foundation for data-driven, proactive road maintenance.

What is reviewed

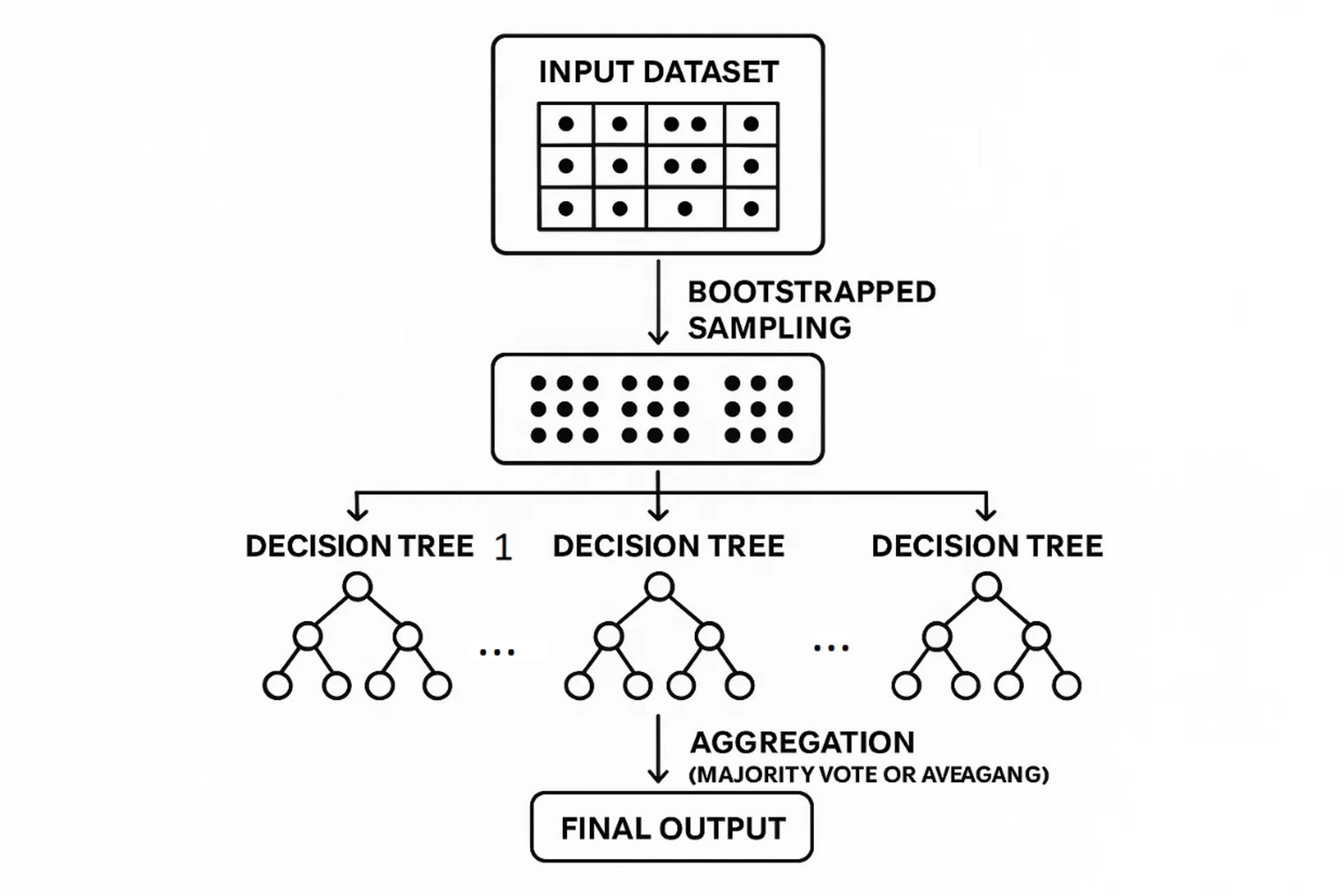

I systematically examine four interconnected areas. First, supervised detection methods, ranging from handcrafted features to modern convolutional neural networks (CNNs) and hybrid CNN–RNN architectures, which extract patterns from visual and sensor data. Second, edge and federated deployment strategies that allow in-field, privacy-preserving monitoring without centralizing sensitive data. Third, reinforcement learning and metaheuristic approaches for maintenance and rehabilitation scheduling, translating detection outputs into cost-effective action plans. Finally, I explore multimodal sensing, combining RGB imagery, thermal cameras, LiDAR, IMU, and ground-penetrating radar (GPR), with a particular focus on subsurface integration to detect latent structural issues.

Key technical takeaways

I found that multimodal fusion is essential for early detection of latent structural problems. Surface-level imagery alone may miss moisture infiltration or base-layer failures, while thermal and GPR signals provide critical depth and diagnostic insight. Edge and federated learning approaches enable inspection fleets to collaborate on model improvement without centralizing raw imagery, effectively balancing privacy, bandwidth, and scalability. Hybrid temporal models, such as CNN combined with LSTM or BiLSTM, reduce false positives on moving platforms by integrating visual and inertial data. Importantly, optimization algorithms close the loop: detected distresses, including crack density, rutting depth, or International Roughness Index (IRI) forecasts, can feed reinforcement learning or metaheuristic schedulers that optimize long-term maintenance and rehabilitation under budgetary, traffic, and environmental constraints. Emerging tools like AutoML and explainable AI further accelerate deployment and improve operator trust, offering neural architecture search for edge models and SHAP/LIME interpretability for predictive maintenance decisions.

Practical recommendations for implementers

I recommend starting with a pragmatic sensor mix. For continuous mapping, RGB cameras and IMU sensors provide robust baseline data, while thermal cameras and GPR are valuable for targeted campaigns where subsurface risk is likely. Benchmarking on the target hardware is critical, evaluating both inference latency and model accuracy on representative embedded GPUs or smartphones. Federated updates allow fleet-scale learning without centralizing raw data, improving scalability and privacy. Domain adaptation is necessary to handle geographic or material shifts, either by collecting a small local labeled set or applying transfer learning techniques. Finally, I emphasize that detection outputs should be directly integrated into maintenance and rehabilitation pipelines, ensuring that maps and predictive insights translate into actionable schedules that account for traffic, cost, and operational constraints.

Research gaps and open challenges

Despite progress, several challenges remain. Public, well-annotated, geographically diverse datasets are still scarce, limiting generalizability. Standardized runtime and on-device benchmarks are needed to evaluate edge AI solutions fairly. Developing robust and reproducible multimodal fusion pipelines, particularly involving GPR, is an active research frontier. Ethical and environmental considerations are also important, including the privacy of geotagged imagery and the carbon footprint of large-scale model training, which require careful mitigation strategies.

Impact beyond pavements

The methodologies I surveyed extend beyond asphalt roads. Similar approaches can be applied to other infrastructure domains, such as bridges and rail tracks, and even non-transport areas including agriculture and medical imaging. Establishing reproducible benchmarks and open datasets will accelerate cross-domain adoption and facilitate more resilient, data-driven infrastructure management practices.

For the full literature synthesis, unified taxonomy, benchmark proposals, and deployment checklists, see:

Asadi, Y. Paving the Future of Intelligent Pavement Defect Detection with Machine Learning: A Comprehensive Survey of Techniques and Applications. Int. J. Pavement Res. Technol. (2026). https://doi.org/10.1007/s42947-026-00711-y

Chinese Translation / 中文翻译:

以机器学习铺就智能沥青病害检测的未来之路

人工路面检测耗时费力且结果参差不齐。本文综述了机器学习、多模态感知及优化方法如何革新沥青病害检测,并将检测结果直接与养护调度相衔接,从而构建更智能、更安全的道路体系。

道路网络对经济活动与公共安全至关重要,然而传统的路面检测仍主要依赖人工且属于被动响应式。目视巡查速度慢、结果不一致且成本高昂,许多结构性损坏始于肉眼不可见的表层之下。在本综述中,我系统梳理了近期机器学习技术的进展,这些技术能够实现更快速、更客观、可预测的路面管理,为数据驱动的主动式道路养护奠定基础。

综述内容

我系统性地审视了四个相互关联的领域。第一,监督式检测方法,涵盖从手工特征到现代卷积神经网络以及CNN-RNN混合架构,这些方法从视觉与传感器数据中提取模式。第二,边缘计算与联邦学习部署策略,支持在不集中敏感数据的前提下进行现场、隐私保护的监测。第三,强化学习与元启发式方法在养护与修复调度中的应用,将检测结果转化为具有成本效益的行动计划。最后,我探讨了多模态感知技术,融合RGB图像、热像仪、激光雷达、惯性测量单元和探地雷达,特别关注用于探测潜在结构问题的地下数据集成。

关键技术要点

研究发现,多模态融合对于早期发现潜在结构问题至关重要。仅靠表层图像可能遗漏水分渗透或基层损坏,而热信号与探地雷达信号则能提供关键的深度信息和诊断洞察。边缘与联邦学习方法使得检测车队能够在无需集中原始图像的情况下协作改进模型,有效平衡隐私、带宽和可扩展性。混合时序模型(如CNN结合LSTM或BiLSTM)通过集成视觉与惯性数据,降低了移动平台上的误报率。重要的是,优化算法完成了闭环:检测到的病害(包括裂缝密度、车辙深度或国际平整度指数预测)可作为输入,驱动强化学习或元启发式调度器,在预算、交通和环境约束下优化长期养护与修复方案。AutoML与可解释AI等新兴工具进一步加速了部署并提升了操作者的信任度,为边缘模型提供了神经架构搜索,并为预测性养护决策提供了SHAP/LIME可解释性。

实施者实用建议

建议从务实的传感器组合入手。对于连续测绘,RGB相机与IMU传感器可提供可靠的基线数据;而在可能存在地下风险的针对性检测中,热像仪和探地雷达则具有重要价值。在目标硬件上进行基准测试至关重要,需在代表性的嵌入式GPU或智能手机上同时评估推理延迟与模型准确性。联邦更新支持车队规模的学习而无需集中原始数据,提升了可扩展性与隐私性。为应对地理或材料差异,领域自适应是必要的,可通过收集少量本地标注数据集或应用迁移学习技术实现。最后,我强调检测输出应直接集成到养护与修复流程中,确保地图与预测性见解能转化为考虑交通、成本与操作约束的可执行计划。

研究缺口与开放挑战

尽管已有进展,若干挑战依然存在。公开、标注良好、地理分布多样的数据集仍然稀缺,限制了模型的泛化能力。需要标准化的运行时与设备端基准来公平评估边缘AI解决方案。开发稳健且可复现的多模态融合流程(尤其是涉及探地雷达的)是当前活跃的研究前沿。伦理与环境考量同样重要,包括地理标签图像的隐私保护以及大规模模型训练的碳足迹,这些都需要审慎的缓解策略。

超越路面领域的应用前景

本文综述的方法论可延伸至沥青路面之外。类似方法可应用于其他基础设施领域,如桥梁与轨道,甚至非交通领域,包括农业与医学影像。建立可复现的基准与开放数据集将加速跨领域应用,并促进更具韧性、数据驱动的基础设施管理实践。

有关完整的文献综述、统一分类体系、基准测试方案及部署清单,请参见:

Asadi, Y. Paving the Future of Intelligent Pavement Defect Detection with Machine Learning: A Comprehensive Survey of Techniques and Applications. Int. J. Pavement Res. Technol. (2026). https://doi.org/10.1007/s42947-026-00711-y

Follow the Topic

-

International Journal of Pavement Research and Technology

The International Journal of Pavement Research and Technology serves as a platform for the global exchange of ideas in pavement engineering and technology.

Please sign in or register for FREE

If you are a registered user on Research Communities by Springer Nature, please sign in