Impact of the aqueous corrosion induced alteration layer on mechanical properties of pharmaceutical glasses

Published in Chemistry, Materials, and Pharmacy & Pharmacology

Behind the paper

Qiuju Zheng, Hongtu He, Yuanzheng Yue

In our new paper published in npj materials degradation “Impact of the aqueous corrosion induced alteration layer on mechanical properties of pharmaceutical glasses”, we provided insight into the profound effects of water corrosion on the surface chemistry and mechanical properties of glass. In this Behind the Paper blog, instead of going into the details of the study, we will tell how this research originated, evolved, and ultimately ended as a publication.

Inspiration

As all we know, the outbreak of the global pandemic (COVID-19) in 2019 affected billions of human lives. Like many scientists, we asked ourselves how we could contribute to mitigating the surge of SARS-CoV-2 infections. One of the mitigating measures is to get people vaccinated to prevent infection of COVID-19. To store and transport various kinds of vaccine, more than 100 billion borosilicate glass vials as packaging materials are needed globally every year. As glass scientists, we began to think about the chemical and mechanical durability of these glass vials in response to their interaction with vaccines, and whether this could potentially impact human health. In this context, the first author, Prof. Qiuju Zheng from Qilu University of Technology in China, initiated a project aiming to understand the structure-property relationship of the pharmaceutical borosilicate glass, which is important for developing the chemically durable pharmaceutical glasses.

To successfully conducted this project, Prof. Zheng’s team has been collaborating with the Shandong Pharmaceutical Glass Co., Ltd. - a global leading producer of pharmaceutical glasses, Prof. Hongtu He’s team (Southwest University of Science and Technology) and Prof. Yuanzheng Yue (Aalborg University, Denmark). Through this collaboration, we realized that the following measures must be taken to ensure the chemical and mechanical stabilities of glass vials. 1) Glass compositions with ultrahigh chemical durability should be designed. 2) the surface and subsurface damage of glass during manufacturing process should be avoided. 3) the contact load during the handing and transportation as well as packaging and storage process should be minimized to prevent potential contact damage on glass surface.

The research team made significant efforts to detect the variations in the surface composition and microstructure change using Time-of-flight secondary-ion mass spectroscopy (ToF-SIMS) and Raman Spectroscopy. The content of the water (i.e., hydrous species) incorporated into the corroded glass surface was determined by sum frequency generation (SFG) spectroscopy, while both surface and subsurface damages of corroded glass were investigated through nanoindentation, nanowear tests and Vickers indentation tests. We found that the water content in the alteration layer is the key factor to affect the mechanical properties. After systematic structural and mechanical analyses, we became clear about how the water content in the glass surface impacts the mechanical properties of the glasses. To the best of our knowledge, our work is the first to reveal the connection between the water content in the alteration layer and the mechanical properties of glass.

Interesting and surprising results

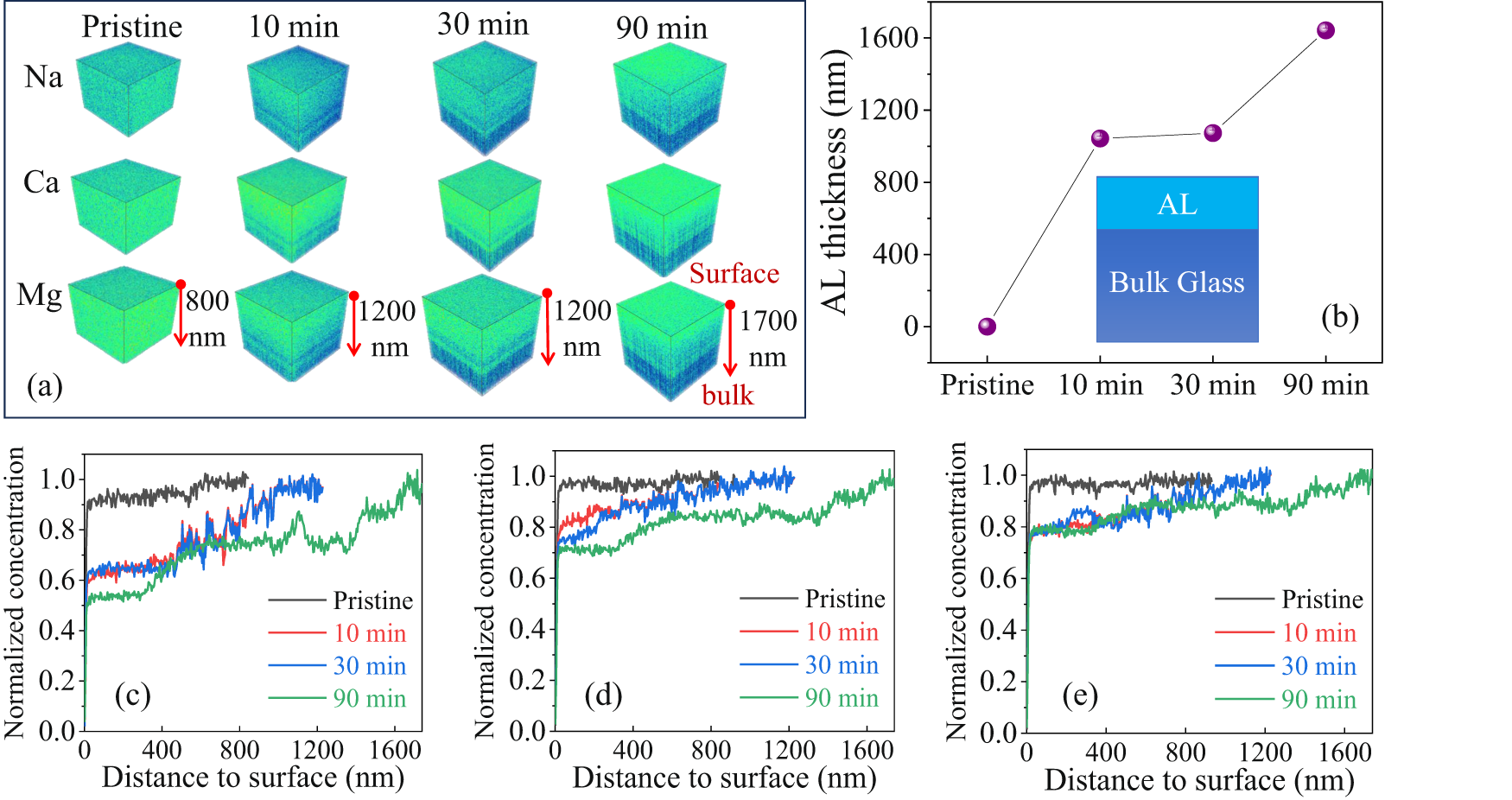

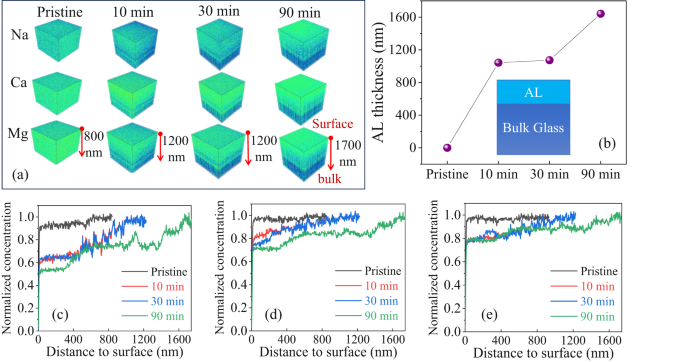

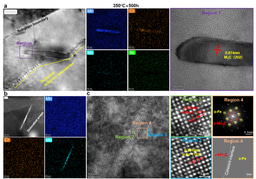

ToF-SIMS and its 3D imaging revealed that the modifying ions in glass structure network such as sodium (Na), Calcium (Ca), and Magnesium (Mg) could be leached out of glass surface, causing the remaining Si-O-Si network change to a “silica-like” or “silica-rich” surface layer, i.e., “alteration layer (AL)”. The thickness of AL increases with the corrosion time (Figure 1).

Figure 1. a ToF-SIMS 3D profile of network modifier distribution in BAS glass surfaces corroded for various time. b Alteration layer thickness of BAS glass treated under various corrosion conditions. The concentration of (c) Na, d Ca, and e Mg are normalized to the silicon concentration at the same sputter depth and then normalized by the bulk concentration of each type of ion.

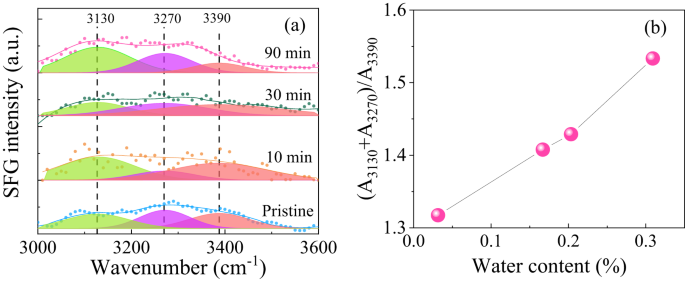

As the modifying ions are leached out, the hydrous species or water-related molecules come into the AL, causing more water content inside the AL on glass surface. This is further confirmed by ToF-SIMS and its 3D imaging of hydrogen (H) as well as Raman spectroscopy. Using the surface sensitive sum frequency generation (SFG) spectroscopy, the adsorbed water molecules on corroded glass surface in humid environments were revealed to have stronger hydrogen-bonding interactions with a shorter O-H…O distance, and such effect was enhanced with increasing the corrosion time (Figure 2).

Figure 2. a SFG spectra of glass surfaces under various corrosion conditions, b Oscillator strength ratio of the sum of ∼3130 cm−1 band (A3130) and ∼3270 cm−1 band (A3270) with the ∼3390 cm−1 band (A3390) as a function of water content in the AL.

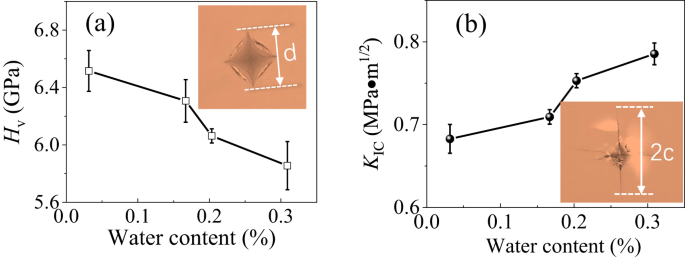

Mechanical tests of corroded glass surfaces confirmed that the mechanical properties of glass surface, involving the nanohardness and the reduced modulus as well as the nanowear resistance and the Vickers hardness decreased with corrosion time (Figure 3a). By correlating the water content in the AL with the mechanical properties of glass surface, the significant role of water on the mechanical degradation of BAS glass was discovered. On the other hand, the indentation fracture toughness of BAS glass increased with corrosion time (Figure 3b), which is not governed by the water content in the AL anymore, but by the corrosion-induced “silica-like” structure in the AL. This was confirmed by the subsurface densification of BAS glass by nanoindentation and nanowear.

Figure 3. a Vickers hardness (HV) and b indentation fracture toughness (KIC) of glass surfaces as a function of water content in AL

In summary, the water and glass interactions can affect the mechanical and chemical properties of glass. The formation of AL, along with the presence of water-related species in the AL, offering us opportunities to design the next generation of pharmaceutical glasses with higher toughness to benefit human’s health in the future. We will continue to reveal the nature of the AL and the water-related species in AL, and thereby find the way to avoid the mechanical and chemical degradation of glass in various applications, contributing to the development of materials science, mechanical engineering, and chemical engineering.

What’s next?

Our methods have opened up a new way to understand the surface chemistry and mechanical properties of glass. We are currently exploring the application of our methods to understand the impacts of surface chemistry changes under various conditions on the mechanical properties of glass.

Where to find our paper?

To find the scientific insight for aqueous corrosion induced AL and its impact on mechanical properties of glass, please read our full paper “Impact of the aqueous corrosion induced alteration layer on mechanical properties of pharmaceutical glasses” published in npj Materials Degradation (2024) 8:17; https://doi.org/10.1038/s41529-024-00431-3.

Follow the Topic

-

npj Materials Degradation

This journal considers basic and applied research that explores all aspects of the degradation of metallic and non-metallic materials. The journal broadly defines ‘materials degradation’ as a reduction in the ability of a material to perform its task in-service as a result of environmental exposure.

Your space to connect: The Fuel cell technologies Hub

A new Communities’ space to connect, collaborate, and explore research on Electrochemistry, Chemical Engineering, and Fuel Cells!

Continue reading announcementRelated Collections

With Collections, you can get published faster and increase your visibility.

Decoding Degradation: Advances in the Materials Genome

Publishing Model: Open Access

Deadline: Mar 20, 2026

Corrosion and Degradation in Nuclear Materials

Publishing Model: Open Access

Deadline: Sep 03, 2026

Please sign in or register for FREE

If you are a registered user on Research Communities by Springer Nature, please sign in