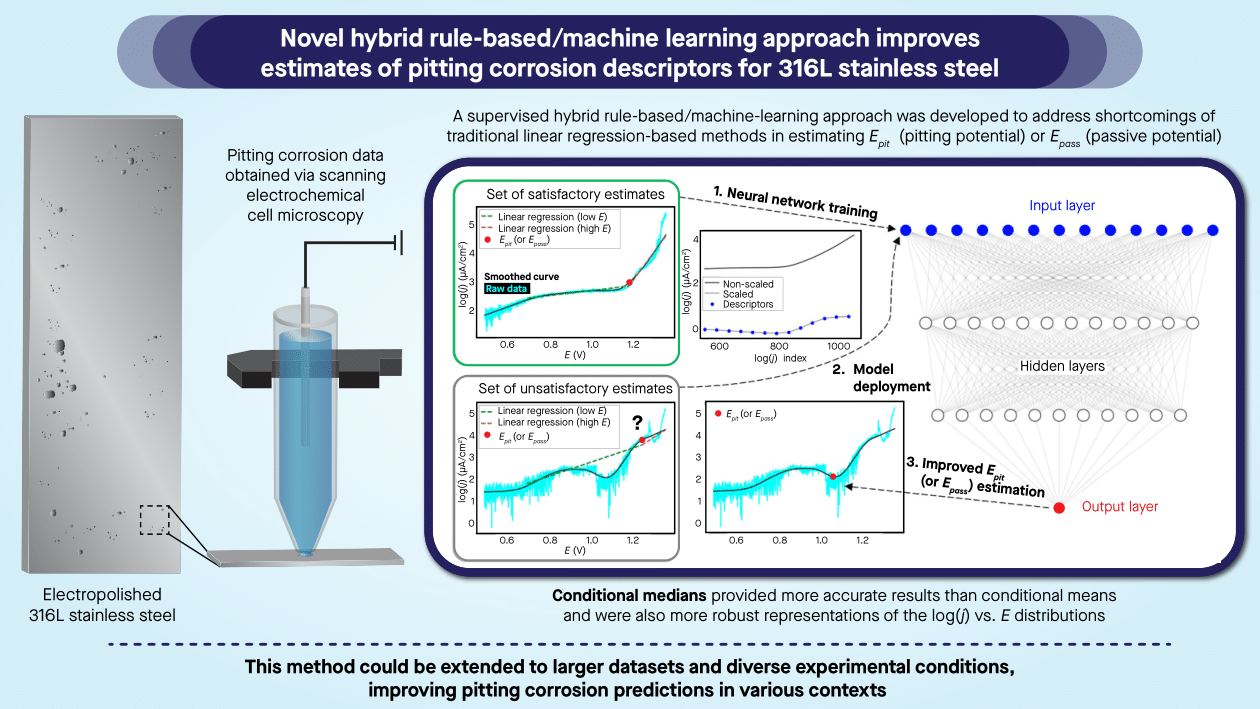

Strong as steel, agile as athletes: data-driven modelling of unpredictable failures

Published in Materials, Computational Sciences, and Mathematics

Can we predict the moment when the strength of a metal or an alloy will give way? This question, seemingly straightforward, shares a surprising relationship with wondering about the career of a high-level athlete; both inquiries resonate with profound significance for the guardians of their respective fields—engineers and physiotherapists alike. These questions don’t merely satisfy a passing curiosity but lay the groundwork for preventing similar failures in the future. We strive to understand the origin, nature, and cause of each unexpected breakdown, whether in the grain of a metal or the muscle fibre of an athlete.

As we endeavour to estimate the “when” of failure, we’re reminded of Benjamin Graham’s wisdom on the margin of safety: it serves to spare us the impossible task of forecasting the future with precision. In essence, a good prediction doesn’t require crystal-clear accuracy—it just needs to be reliable enough to keep us within the bounds of safety.

Take stainless steel, for example, appraised for its outstanding corrosion resistance—it thrives where other metals start to fail, maintaining its passivity even in environments with high corrosiveness. The tenacity under stress of the alloy makes me remember Michael Jordan’s iconic game-winner against Georgetown in 1982, a narrative recounted in the 2023 movie “Air.” Yet, even high-grade stainless steels have their Achilles’ heel: pitting corrosion. This localised attack can spring from the smallest defect, leading to potential collapse. Like the unpredictability of stable pitting growth, predicting the exact moment of an athlete’s injury (physical or psychological), as in the case of Simone Biles’ withdrawal during the Tokyo 2020 Olympics, remains a challenge.

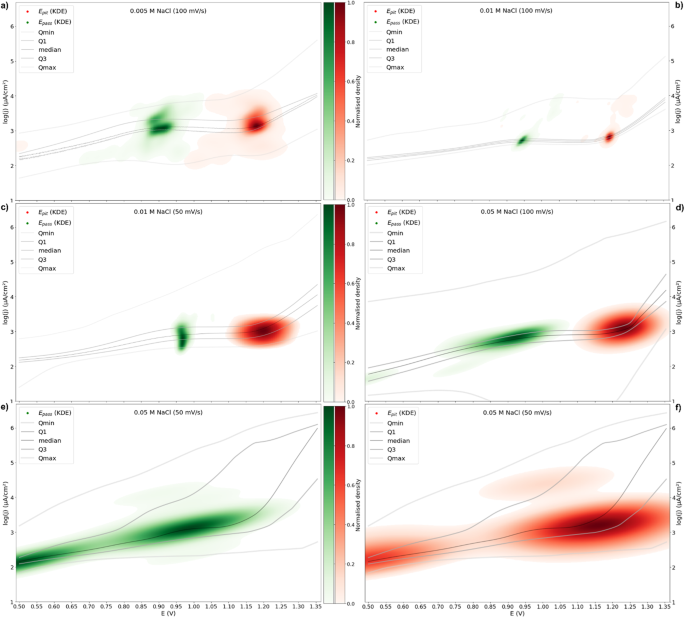

Our predictions, especially concerning rare and extreme “tail events,” are notoriously imprecise1. To improve our foresight, researchers have devised accelerated laboratory tests, such as potentiodynamic polarisation curves (PP), that impose severe conditions on materials to uncover all potential failure modes2. These tests mirror an athlete’s exhausting training regimen, attempting to simulate and prepare for real-world challenges. However, despite the rigour of these simulations, an element of unpredictability lingers, echoing Morgan Housel’s reasoning that growth is a slow build while destruction can strike instantly3.

Pitting corrosion is like a perfect storm, arising when inherent material weaknesses meet with unexpectedly harsh external conditions. These scenarios are reminiscent of Michael Jordan’s phrase about the playoffs revealing true character. In the same vein, engineers must differentiate between a metal’s everyday resilience and performance when faced with extraordinary stress.

The quest for a deeper understanding of these failure mechanisms is gaining momentum, thanks to an influx of data and novel approaches like transfer learning: in the corrosion field, Vincent Vangrunderbeek suggests transfer learning to refine long-term predictions based on accelerated test data4. But the thirst for data is insatiable; more than ever, we shall approach materials R&D with a “Black Mamba mentality,” tirelessly exposing materials to a spectrum of failure scenarios, much like the relentless pursuit of excellence in sports.

To parse through the complexities of these variables, we propose a data-driven method: a machine learning-based model that uses PP data to predict pitting incidents5. The erratic nature of the corrosion response—heteroscedastic, as the jargon goes—necessitates a sophisticated approach that can navigate the waters of big data6.

Source: https://www.instagram.com/p/lB65GLxNt8/?hl=en

We cannot afford an indifferent posture toward Allen Iverson’s infamous “practice” attitude: success in materials research cannot rely on raw talent only but on the rigours of repetitive testing and robust data collection. We hope these comprehensive “practice sessions” will provide us with reliable “training data” to refine our predictive models7.

In the end, like athletes, no stainless steel can expect to “miss practice” and still shine in the game in the long run. The bar is set high for us: continually progressing our understanding and predictive capabilities to ensure the integrity and reliability of the materials that constitute our physical world.

References

- Taleb, N. N. The Black Swan: THE IMPACT OF THE HIGHLY IMPROBABLE. (Penguin Books, 2008).

- Hughes, A. et al. Corrosion Inhibition, Inhibitor Environments, and the Role of Machine Learning. Corros. Mater. Degrad. 3, 672–693 (2022).

- Housel, M. The Psychology of Money: Timeless lessons on wealth, greed, and happiness. (Harriman House Limited, 2020).

- Vangrunderbeek, V. et al. Exploring the potential of transfer learning in extrapolating accelerated corrosion test data for long-term atmospheric corrosion forecasting. Corros. Sci. 225, 111619 (2023).

- Coelho, L. B. et al. Estimating pitting descriptors of 316 L stainless steel by machine learning and statistical analysis. npj Mater. Degrad. 7, 82 (2023).

- Coelho, L. B. et al. Probing the randomness of the local current distributions of 316 L stainless steel corrosion in NaCl solution. Corros. Sci. 217, 111104 (2023).

- Coelho, L. B. et al. Reviewing machine learning of corrosion prediction in a data-oriented perspective. npj Mater. Degrad. 6, (2022).

Follow the Topic

-

npj Materials Sustainability

This is an open access, transdisciplinary journal presenting high-quality research that advances the scientific understanding and engineering design of materials with respect to the sustainability of their production, use and re-use.

-

npj Computational Materials

This journal publishes high-quality research papers that apply computational approaches for the design of new materials, and for enhancing our understanding of existing ones.

-

npj Materials Degradation

This journal considers basic and applied research that explores all aspects of the degradation of metallic and non-metallic materials. The journal broadly defines ‘materials degradation’ as a reduction in the ability of a material to perform its task in-service as a result of environmental exposure.

Related Collections

With Collections, you can get published faster and increase your visibility.

Computational Catalysis

Publishing Model: Open Access

Deadline: Mar 31, 2026

Recent Advances in Active Matter

Publishing Model: Open Access

Deadline: Sep 01, 2026

Please sign in or register for FREE

If you are a registered user on Research Communities by Springer Nature, please sign in