Improving the degradation and magnetization performance of FePC amorphous alloys by annealing treatment

Published in Materials

Behind the paper

Zhigang Qi, Weimin Wang, Xihua Zhang

In our new paper published in npj materials degradation “Improving the degradation and magnetization performance of FePC amorphous alloys by annealing treatment”, we investigated the effects of annealing treatment on the dye degradation performance and magnetization performance of FePC amorphous ribbons. In this blog post, instead of going into the details of the study, we will tell how this research originated, evolved, and ultimately ended as a publication.

Inspiration

The extensive use of synthetic dyes in printing and dying industries has brought serious environmental problems [1]. Owing to their high surface active sites induced by disordered atomic packing structure and residual internal stress, Fe-based amorphous alloys ribbons are one of the catalysts which are applied in degrading various printing and dying wastewaters [2].

The energy-efficient and time-saving annealing treatment is one of the methods, which applies to improve the degradation performance of Fe-based amorphous alloys ribbons [3, 4]. However, the mechanism of annealing still needs to be further clarified. For example, Chen et al found that the multiphase annealed (Fe73.5Si13.5B9Nb3Cu1)91.5Ni8.5 ribbons show much better degradation performance in Orange II than their metallic glass counterparts [5], while it is also reported that Fe78Si9B13 amorphous ribbons showed better degradation performance for 3,5-dichlorosalicylic acid dye solution compared to their annealed ribbons [6].

On the other hand, the annealing treatment is an important method to improve the magnetization performance of the amorphous alloys [7, 8]. Besides, it is reported that the external magnetic field can remarkably enhance the degradation performance of Fe78Si9B13 amorphous ribbons [9]. However, almost no research has studied the relationship between magnetization and degradation performance of annealed Fe based amorphous.

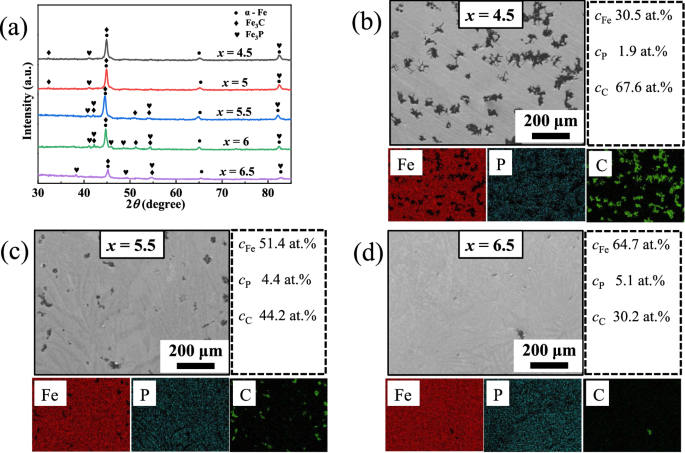

Thus, we prepared the Fe80PxC20-x (4.5 ≤ x ≤ 6.5) amorphous ribbons and annealed them. Meanwhile, we investigated the inner mechanism of improving the dye degradation performance of FePC amorphous ribbons by annealing treatment and explored the relationship between degradation and magnetization performance of FePC amorphous and annealed ribbons.

Surprising results

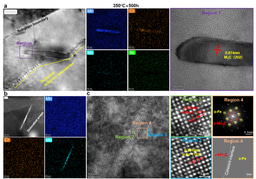

With increasing annealing temperature (Tan), the degradation performance and reusability of the ribbons with cP = 4.5 at.% get better gradually and these of the ribbons with cP = 6.5 at.% become better firstly and then worse. Correspondingly, with increasing Tan, the primary a-Fe grain size of the ribbons with cP = 4.5 at.% increases and their C atom segregation degree rises gradually; meanwhile, the a-Fe grain size of the ribbons with cP = 6.5 at.% increases firstly and then decreases, due to the formation of eutectic a-Fe + Fe3C + Fe3P phases at high Tan. The Tan-dependent similarity between the a-Fe size and the degradation performance/reusability of measured ribbons can be explained by the size effect of galvanic cells in the ribbons’ amorphous matrix and a-Fe precipitation: the larger the a-Fe size, the stronger the electron transportation [10].

Meanwhile, the saturation magnetisation (Bs) and coercivity (Hc) of the ribbons with cP = 4.5 and 6.5 at.% increase with increasing Tan, which shows a near-linear relationship between the reaction rate constant k and ln (Bs·Hc). According to the previous research [11], the additional magnetic field can generate the gradient magnetic force on the surface, which can accelerate Fe3+/Fe2+ cycle for Fenton like reaction. The Fenton-like reaction of the ribbons takes place under the magnetic stirring, so the ribbons are affected by the additional magnetic field. With increasing Bs, the gradient magnetic force increases, which can improve the degradation performance of the ribbons finally. Besides, the Hc represents the ability of the material to resist demagnetization after magnetization [12]. Thus, with increasing Hc, the demagnetization resistance of the ribbons increases and the ribbons are more affected easily by additional magnetic field continually, which can also improve the degradation performance of the ribbons.

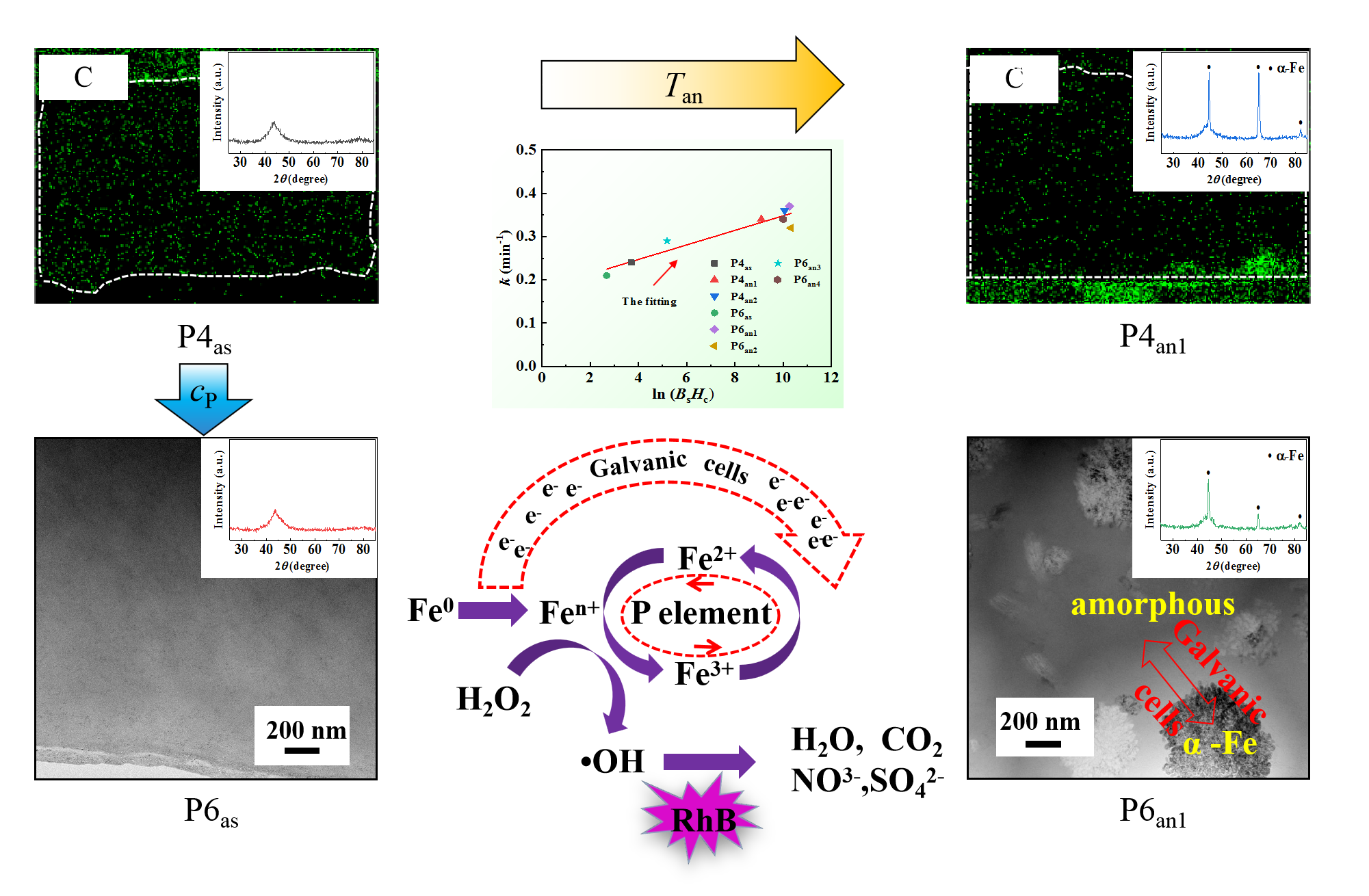

Fig. 1 Schematic illustration of the pathway of RhB solution degradation for as spun and annealed Fe80PxC20-x (x = 4.5 and 6.5) ribbons (P4as, P4an1, P6as and P6an1). Includes the element mapping and XRD analysis of P4as and P4an1, the LRTEM images and XRD analysis of P6as and P6an1, the reaction rate constant k vs. ln (Bs·Hc) of all the ribbons and the pathway of RhB solution degradation for the ribbons.

Fig. 1 shows the schematic illustration of the pathway of RhB solution degradation for as spun and annealed Fe80PxC20-x (x = 4.5 and 6.5) ribbons (P4as, P4an1, P6as and P6an1). Increasing cP can accelerate Fe3+/Fe2+ cycle in the ribbons for Fenton like reaction. Meanwhile, the annealing treatment can promote the precipitation and growth of a-Fe grains in the ribbons. The existence of a-Fe grains with large size facilitates the formation of galvanic cells and promotes inner electron transportation. Thus, the annealed ribbon with cP = 6.5 at.% have better degradation performance and reusability than the others. Meanwhile, the Bs and Hc of the ribbons with cP = 4.5 and 6.5 at.% increase with increasing Tan, which shows a near-linear relationship between the k and ln (Bs·Hc). This work not only studies the mechanism of improving degradation performance for FePC amorphous alloys by annealing treatment, but also reveals a correlation between degradation performance and magnetization performance of FePC alloys.

Where to find our paper?

For more details, please read our full paper “Improving the degradation and magnetization performance of FePC amorphous alloys by annealing treatment” published in npj Materials Degradation (2024) 8:28; https://doi.org/10.1038/s41529-024-00449-7.

References:

[1] Núñez J. et al. Application of electrocoagulation for the efficient pollutants removal to reuse the treated wastewater in the dyeing process of the textile industry. J. Hazard. Mater. 371, 705-711 (2019).

[2] Zhang L. C., Jia Z., Lyu F., Liang S. X. & Lu J. A review of catalytic performance of metallic glasses in wastewater treatment: Recent progress and prospects. Prog. Mater. Sci. 105, 100576 (2019).

[3] Chen S. Q. et al. Multi-phase nanocrystallization induced fast degradation of methyl orange by annealing Fe-based amorphous ribbons. Intermetallics. 90, 30-35 (2017).

[4] Chen Q. et al. Nanostructured metallic glass contributing to efficient catalytic degradation of dye wastewater. J. Non-Cryst. Solids. 598, 121952 (2022).

[5] Chen S. Q. et al. Unexpected high performance of Fe-based nanocrystallized ribbons for azo dye decomposition. J. Mater. Chem. A. 5, 14230-14240 (2017).

[6] Zhang L. B. et al. Insight into efficient degradation of 3,5-dichlorosalicylic acid by Fe-Si-B amorphous ribbon under neutral condition. Applied Catalysis B: Environmental. 294, 120258 (2021).

[7] Herzer G. Modern soft magnets: Amorphous and nanocrystalline materials. Acta Mater. 61, 718-734 (2013).

[8] Han M. et al. Revealing the effect of rapid annealing on nano-crystallization behavior and soft magnetic properties of Fe-Co-B amorphous alloy. Journal of Materials Research and Technology. 26, 5425-5436 (2023).

[9] Ge Y. X. et al. Remarkably enhanced Fenton-like catalytic activity and recyclability of Fe-based metallic glass by alternating magnetic field: mechanisms and industrial applications. J. Mater. Chem. A. 10, 23314-23322 (2022).

[10] Liang S. X. et al. Compelling rejuvenated catalytic performance in metallic glasses. Adv. Mater. 30, 1802764 (2018).

[11] Zhou T. et al. Rapid decomposition of diclofenac in a magnetic field enhanced zero-valent iron/EDTA Fenton-like system. Chemosphere. 193, 968-977 (2018).

[12] Zha L. et al. Growth of quasi-texture in nanostructured magnets with ultra-high coercivity. Acta Mater. 195, 282-291 (2020).

Follow the Topic

-

npj Materials Degradation

This journal considers basic and applied research that explores all aspects of the degradation of metallic and non-metallic materials. The journal broadly defines ‘materials degradation’ as a reduction in the ability of a material to perform its task in-service as a result of environmental exposure.

Related Collections

With Collections, you can get published faster and increase your visibility.

Decoding Degradation: Advances in the Materials Genome

Publishing Model: Open Access

Deadline: Mar 20, 2026

Corrosion and Degradation in Nuclear Materials

Publishing Model: Open Access

Deadline: Sep 03, 2026

Please sign in or register for FREE

If you are a registered user on Research Communities by Springer Nature, please sign in