Low-temperature sintering of Ag nanoparticles for high-performance thermoelectric module design

Published in Materials

The use of conventional fillers often leads to the dilemma of low operating temperature (unfavorable for the output power of the thermoelectric device) or high welding temperature (unfavorable for the thermal stability of the thermoelectric material). In other words, the lack of non-destructive connection technology has hindered the development of medium- and high-temperature thermoelectric devices (especially those incorporating temperature-sensitive and phase-change materials).

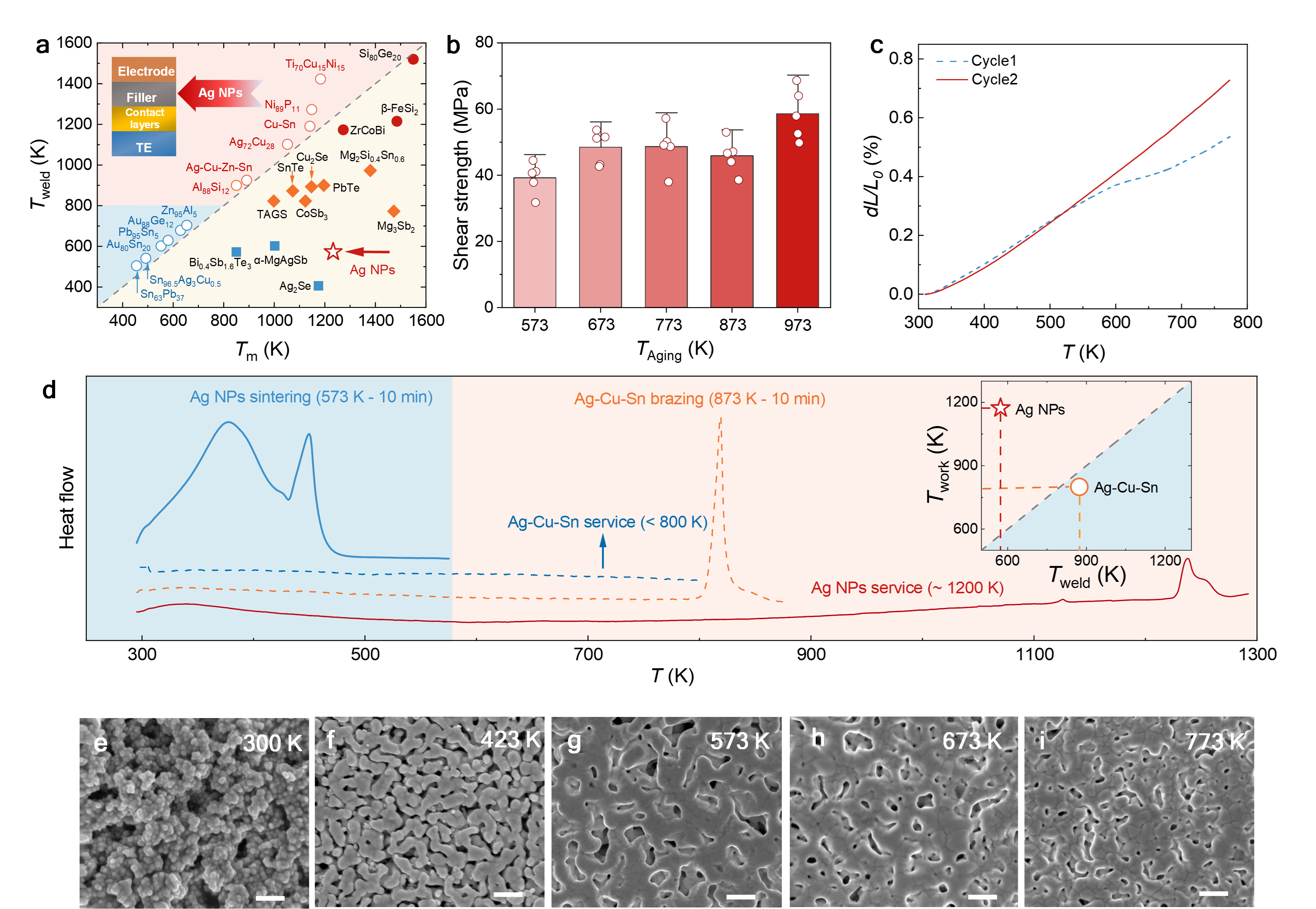

Figure. 1 | Characterization of Ag NPs and corresponding sintered junctions. (a) Welding temperatures (Tweld) of traditional fillers, thermoelectric materials, and silver nanoparticles (Ag NPs) vs. their respective melting temperatures (Tm). Dashed line: Tweld = Tm. Inset: schematic illustration of the designed contact between the thermoelectric material and the electrode in the module, showing where Ag NPs are applied. (b) Variation of shear strength of Ag NP junctions (sintered at 573 K) with aging temperature. (c) Thermal expansion behaviors of Ag NPs at 300-773 K after being sintered at 573 K. (d) DSC heat flow curves for Ag NPs and Ag-Cu-Sn brazing alloy during simulated sintering and high-temperature service processes. Inset: Maximum service temperatures of Ag NPs and Ag-Cu-Sn vs. their welding temperature. Dashed line: Twork = Tweld. Surface morphology of Ag NPs sintered (e) at 300 K, (f) at 423 K, (g) at 573 K, and after sintering at 573 K aging (h) at 673 K and (i) 773 K.

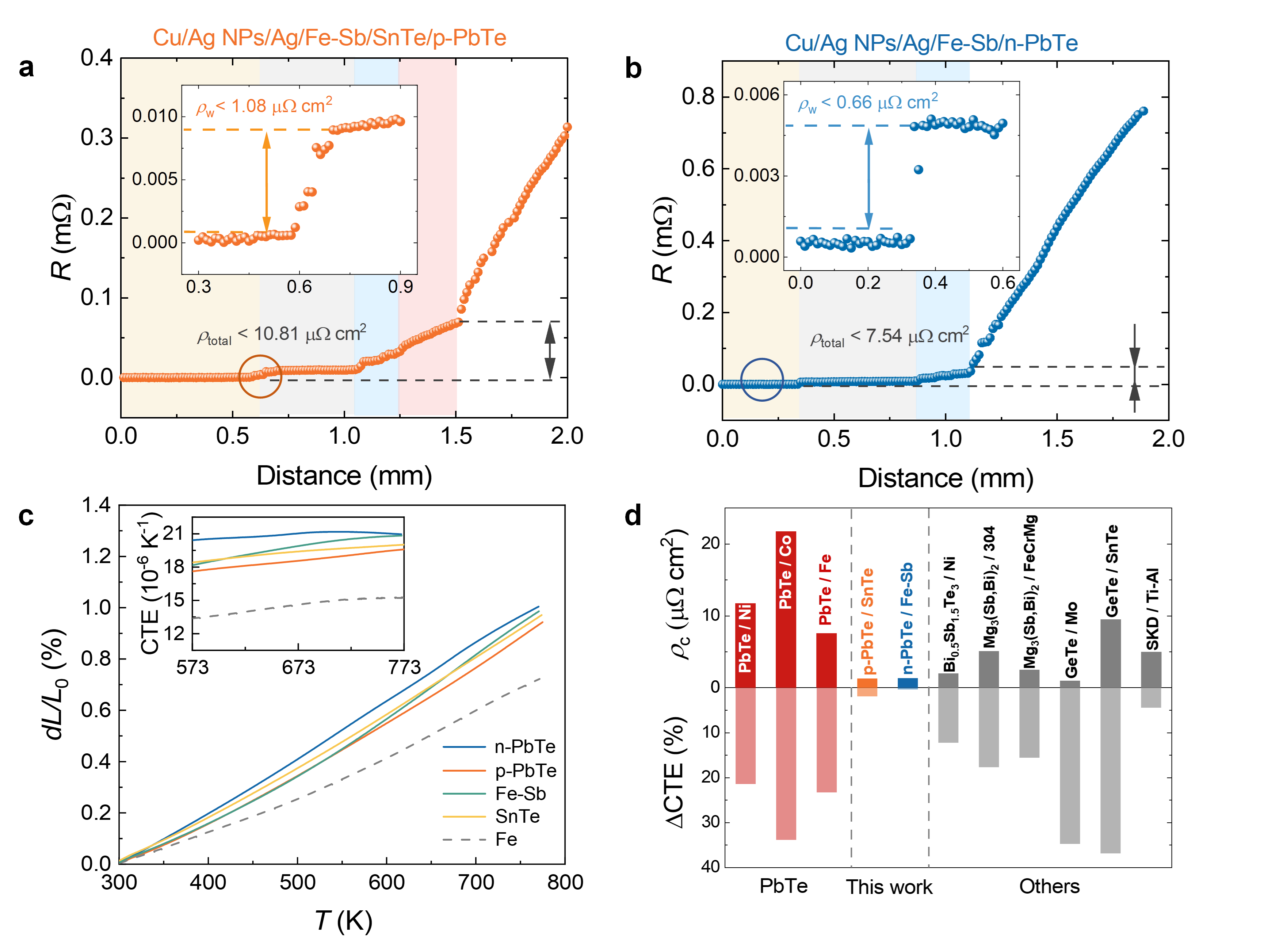

Fe-Sb and SnTe have been selected as connection materials to match the thermal expansion of PbTe, and negligible electrical contact resistivity (ρc) and the difference in the coefficient of thermal expansion (∆CTE) have been realized (Figure 2).

Figure. 2 | Characterization of the PbTe-based module connection layer. Measured contact resistivity (ρc) after Ag NP sintered bonding for the (a) p-type and (b) n-type junctions. Insets to (a) and (b): magnified images of the Ag NP sintered interface for the p-type and n-type junctions marked with circles, and the welding contact resistivity (ρw). (c) Temperature-dependent expansion behaviors of PbTe and connection materials in the range 293-773 K. Inset: CTE variation of the corresponding materials at 573-773 K. (d) Contact resistivity (ρc) and ∆CTE for this connection design in comparison with those from other reports.

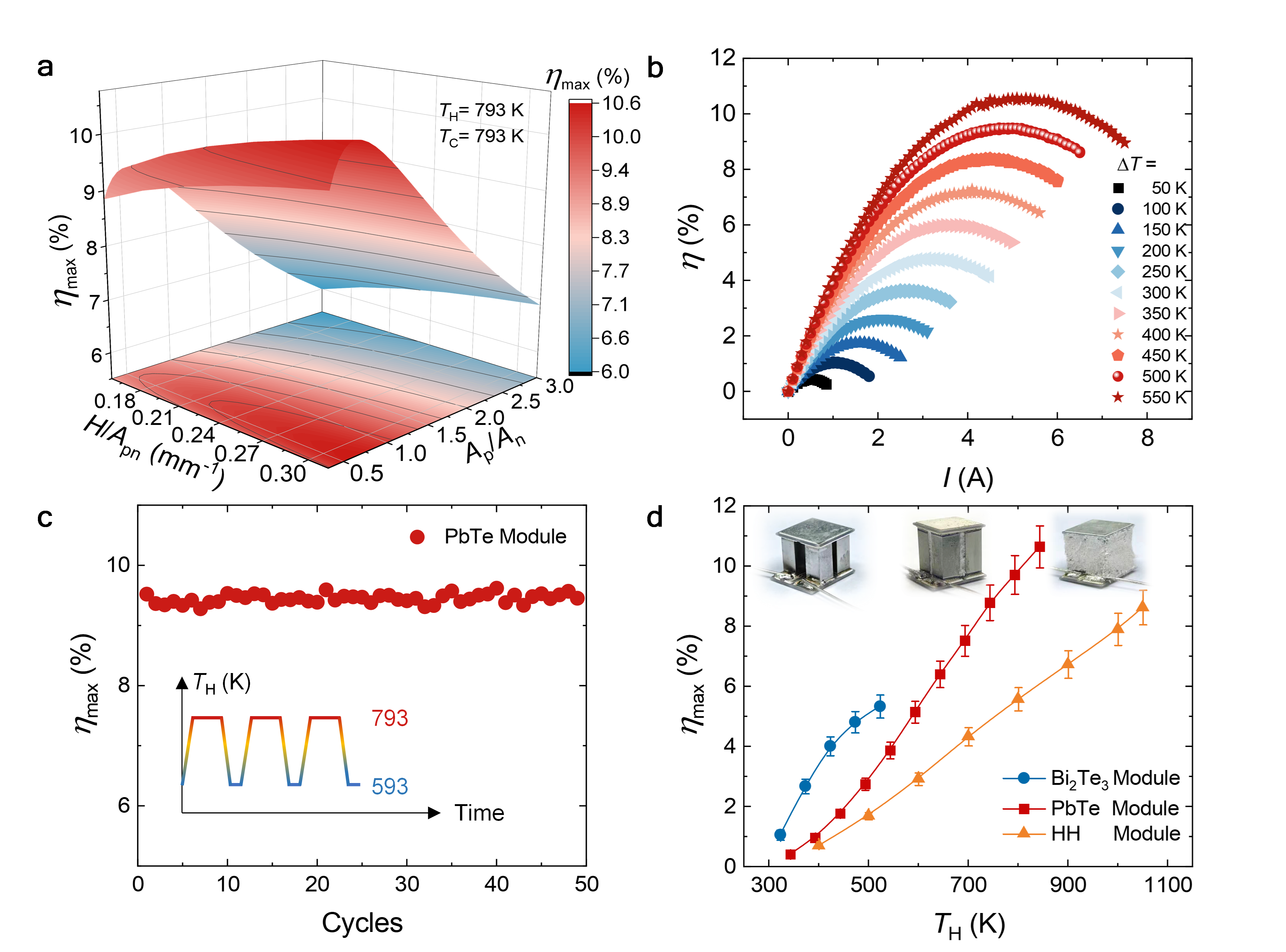

A record high energy conversion efficiency of ~11% in a single-stage PbTe module at a temperature difference of 550 K has been realized, and the performance is higher than that of previous reports. More importantly, this low-temperature sintering technology has also been applied to the fabrication of low-temperature Bi2Te3-based and high-temperature half-Heusler-based modules. Due to the advantages of this technique, the module preparation process can be greatly simplified, a wide service temperature range (from room temperature up to 1233 K) can be realized, and the impact of welding thermal cycles (to further improve module efficiency) can be minimized. This technology can effectively overcome the major obstacle in the preparation of thermoelectric modules, and is suitable for almost all thermoelectric materials (Figure 3).

Figure. 3 | Performance of the thermoelectric modules. (a) Finite-element-simulated maximum efficiency (ηmax) as a function of the cross-sectional area ratio of the p- and n-type legs (Ap/An) and the ratio of height to the total cross-sectional area of the legs (H/Apn). (b) Measured conversion efficiency as a function of current at different hot-side temperatures. (c) ηmax of the PbTe-based module throughout thermal cycling between hot-side temperatures of 593 and 793 K. Inset: schematic illustration of the thermal cycling over time. (d) Maximum conversion efficiency (ηmax) as a function of hot-side temperature for the Bi2Te3-based, PbTe-based, and half-Heusler-based modules. Insets: optical images of (left to right) the Bi2Te3-based, PbTe-based, and half-Heusler-based modules.

This work titled “Low-temperature sintering of Ag nanoparticles for high-performance thermoelectric module design” was published in the latest volume of Nature Energy (https://www.nature.com/articles/s41560-023-01245-4).

Follow the Topic

-

Nature Energy

Publishing monthly, this journal is dedicated to exploring all aspects of this on-going discussion, from the generation and storage of energy, to its distribution and management, the needs and demands of the different actors, and the impacts that energy technologies and policies have on societies.

Related Collections

With Collections, you can get published faster and increase your visibility.

Microgrids and Distributed Energy Systems

Publishing Model: Hybrid

Deadline: Mar 31, 2026

Please sign in or register for FREE

If you are a registered user on Research Communities by Springer Nature, please sign in