Uncover the story behind stable nanocrystalline thin films

Published in Materials

Nanocrystalline thin films show highly attractive material properties, such as high hardness, strength and wear resistance. Therefore, it makes such thin films very interesting for engineering applications. However, a big drawback concerns the emerging large residual stresses that result from their fabrication by deposition and the subsequent susceptibility to defects. One solution, as suggested by 1, is to stabilize the nanocrystalline structure by alloying with a minority element.

Tungsten-titanium (W-Ti) thin films represent an interesting nanocrystalline system, not only from the scientific point of view but also for industrial applications, e.g. as for diffusion barriers in the semiconductor industry. Nevertheless, the mechanism behind the stability of nanocrystalline thin films was not really clear until now.

Commonly, the material structure influences the material characteristics, therefore information about the structure-property relationship is a key ingredient to uncover the story behind stable nanocrystalline thin films.

Utilizing advanced field emission electron microscopy and high-resolution transmission electron microscopy, we have the possibility to gain a profound knowledge about the underlying microstructure and chemical element distribution within the nanocrystalline thin film.

The local detection of the emerging residual stress over the thickness represents a major challenge. Methods, which are material and surface independent, can be utilized in a lab environment as well as enable possibilities for automated acquisition, are clearly in favor.

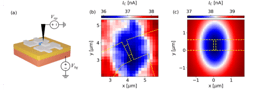

Therefore, the group Brunner at MCL, Austria, utilizes the ion layer removal (ILR) method, an in-situ focused ion beam-scanning electron microscopy (FIB-SEM)-based approach, to detect locally the residual stress within the nanocrystalline thin films. We fabricate micro-cantilevers showing different titanium concentrations (at% Ti). The deflection of the cantilever is selectively modified by removing material by the ion beam in the so called ILR-zone at nm-scales. A general regression neural network (GRNN) is developed to extract the resulting deflection automatically from the generated SEM data. Further, the extracted deflection as a function of the milled material thickness is used to determine the local residual stress along the film by applying finite element modelling. The obtained stress distribution on nm-scales, is correlated with the performed microstructure analysis accompanied with elemental analysis. In addition, machine learning helps to predict the residual stress crossing between the compressive to the tensile regime with respect to the minority element concentration.

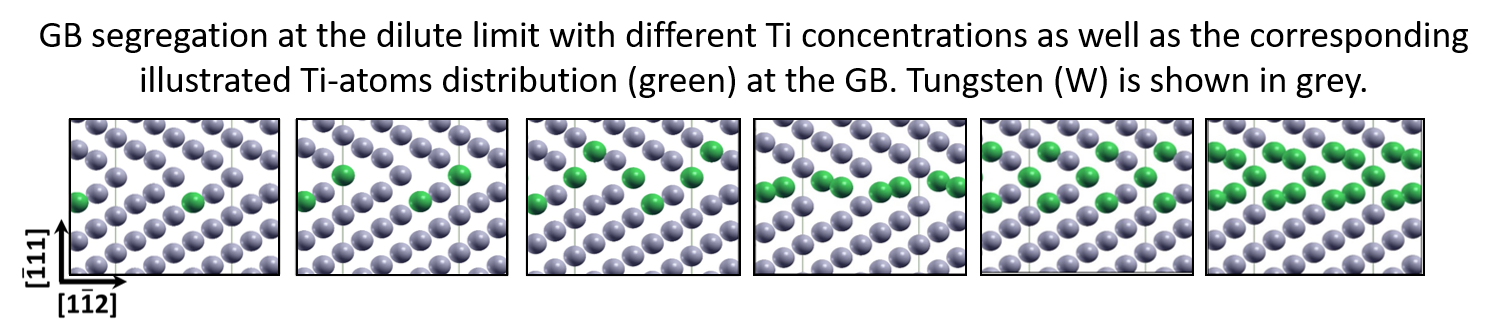

The findings are linked with density functional theory to inquire why the observed Ti enrichment can be strongly reduced at smaller concentrations. We show how it significantly affects the stress configuration stored in the nanocrystalline thin film. For the first time, a thermodynamic treatment of both the bulk and the grain boundary with ab-initio calculations is demonstrated by this work.

The presented results provide a deeper understanding about the stabilization of nanocrystalline thin films by alloying with a minority element. The unique framework linking experimental, and modelling methods as well as machine learning assisted analysis gives insights into how the minority element concentration within nanocrystalline thin films impacts the residual stresses generated after the deposition process. Ti enrichment can be strongly reduced at smaller concentrations. It significantly affects the stress stored in the nanocrystalline thin films. Thus, the consideration of the concentration dependent interaction between the minority element and host element in the bulk and at the grain boundary is crucial.

A link to the manuscript can be found here: Probing the composition dependence of residual stress distribution in tungsten-titanium nanocrystalline thin films | Communications Materials (nature.com)

1. Chookajorn, T., Murdoch, H. A. & Schuh, C. A. Design of stable nanocrystalline alloys. Science 337, 951–954 (2012).

Follow the Topic

-

Communications Materials

A selective open access journal from Nature Portfolio publishing high-quality research, reviews and commentary in all areas of materials science.

Related Collections

With Collections, you can get published faster and increase your visibility.

Advanced characterizations of high-entropy materials

Publishing Model: Open Access

Deadline: Mar 31, 2026

Fundamental science and applications of silk proteins

Publishing Model: Open Access

Deadline: Mar 31, 2026

Please sign in or register for FREE

If you are a registered user on Research Communities by Springer Nature, please sign in