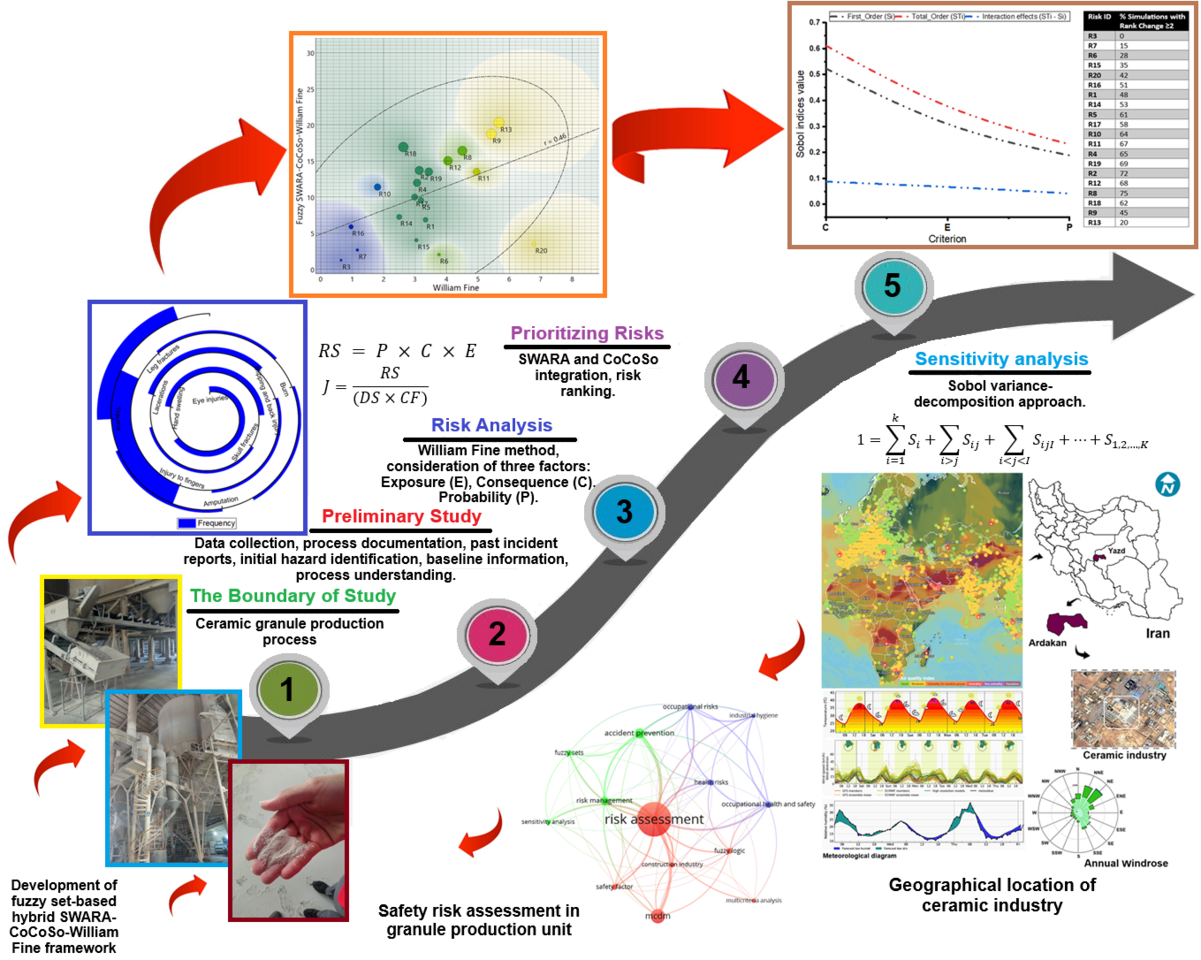

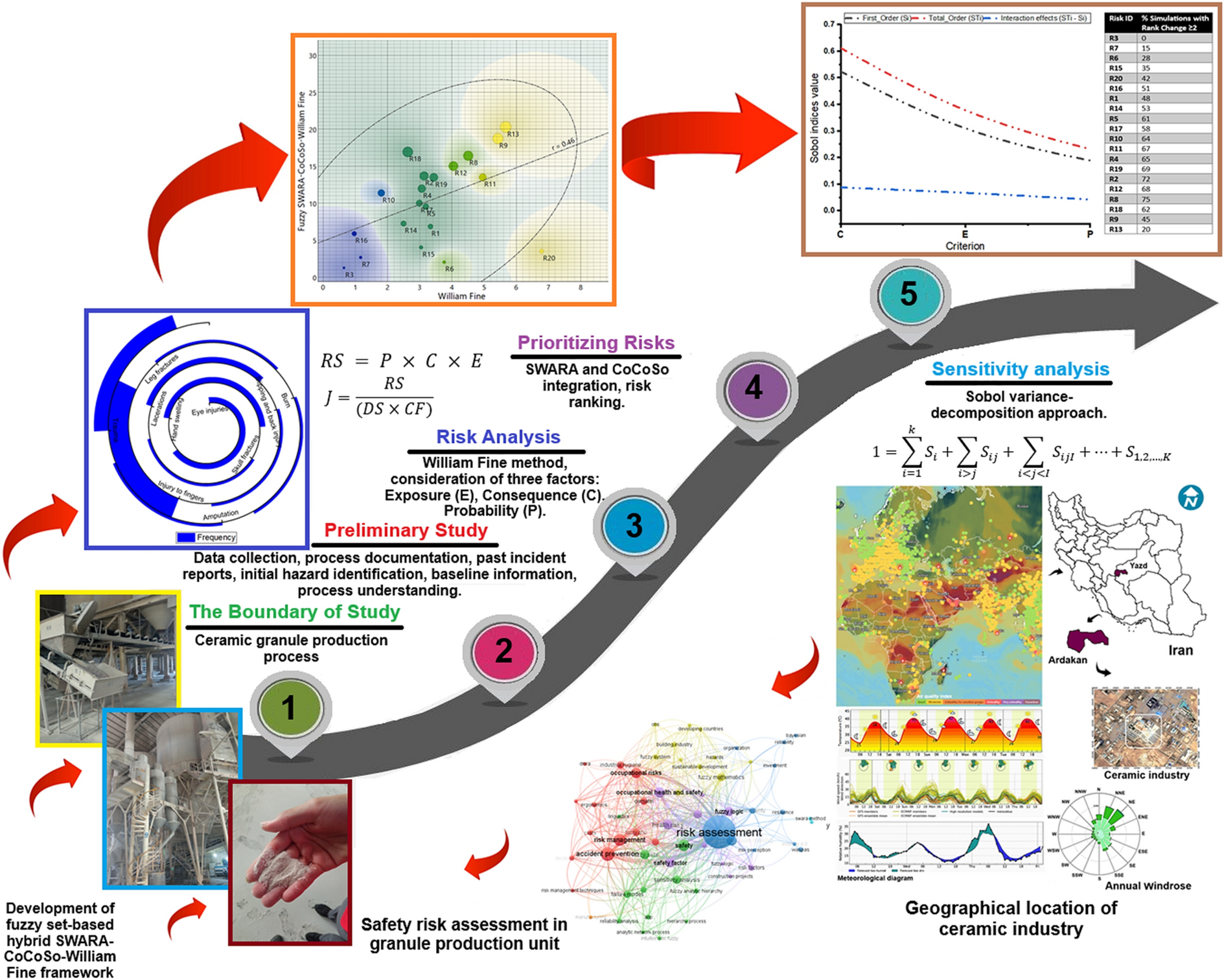

A fuzzy set-based hybrid SWARA-CoCoSo-William Fine framework for safety risk assessment in a ceramic granule preparation unit

Published in Civil Engineering, Mathematics, and Statistics

This study addresses the challenge of uncertainty in Occupational Health and Safety Risk Assessment (OHSRA) by proposing a novel hybrid framework. The authors enhance the traditional William Fine risk assessment method by integrating two fuzzy Multi-Criteria Decision-Making (MCDM) techniques.

Core Methodology: The framework combines:

-

Fuzzy SWARA (Step-wise Weight Assessment Ratio Analysis): Used to determine the relative weights of the three William Fine criteria—Consequences (C), Exposure (E), and Probability (P)—under uncertainty, using linguistic expert judgments transformed into Triangular Fuzzy Numbers (TFNs).

-

Fuzzy CoCoSo (Combined Compromise Solution): Used to rank the 20 identified workplace hazards based on the weighted criteria, providing a more nuanced prioritization than the simple multiplicative score of the traditional method.

Case Study: The model was applied to the granule preparation unit of an Iranian ceramic factory, identifying risks ranging from dust exposure and equipment entrapment to poor ergonomics and noise.

Key Findings:

-

Criterion Weights: Consequence (C) was deemed the most critical factor (weight ~0.46), followed by Exposure (E, ~0.31) and Probability (P, ~0.23).

-

Top-Priority Risks: Both the traditional and hybrid models identified the same critical risks requiring immediate control:

-

R3: Dust emission during soil transfer.

-

R7: Excessive noise from sieves and pumps.

-

R6: Poor ergonomics in manual handling.

-

R15: Poor illumination in work areas.

-

-

Enhanced Discrimination: The fuzzy hybrid model provided a more refined and stable ranking of medium-priority risks compared to the traditional method, which often grouped hazards with similar scores.

-

Robustness Validation: A Sobol sensitivity analysis (via 10,000 Monte Carlo simulations) confirmed the model's stability. The Consequence (C) criterion had the strongest influence on the output, and the rankings for the highest and lowest-priority risks were highly stable despite weight variations.

Conclusion & Contribution: The integrated Fuzzy SWARA-CoCoSo-William Fine framework successfully incorporates expert judgment ambiguity, offers a systematic weighting and ranking process, and delivers more robust, transparent, and reproducible risk prioritization. It provides safety managers with a superior decision-support tool for targeting resources and implementing control measures (like Local Exhaust Ventilation for dust, hearing protection for noise, and ergonomic interventions) in complex industrial environments like ceramic manufacturing.

Follow the Topic

-

Proceedings of the Indian National Science Academy

This is a peer-reviewed journal, publishing original research and reviews across various scientific disciplines. The journal covers a broad range of scientific fields including physics, chemical sciences, earth & planetary sciences, and more.

Please sign in or register for FREE

If you are a registered user on Research Communities by Springer Nature, please sign in