Advancements and Innovations in Low-Temperature Hydrogen Electrochemical Conversion Devices Driven by 3D Printing Technology

Published in Chemistry and Mechanical Engineering

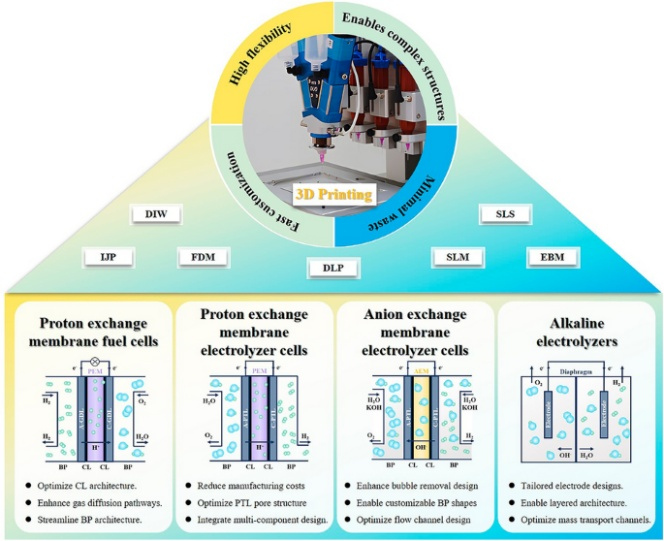

As global hydrogen demand surges, the high cost and long lead times of traditional machining limit the scale-up of PEM fuel cells and water electrolyzers. Now, a multi-institution team led by Prof. Min Wang (China University of Petroleum), Prof. Gaoqiang Yang (Hunan University) and Prof. Feng-Yuan Zhang (University of Tennessee) has delivered a comprehensive roadmap on additive-manufacturing every key component—CL, GDL, PTL, BP—at <100 °C. The work shows how 3D printing can cut platinum use, eliminate assembly steps and push devices to 2 A cm-2, offering a fast track to low-cost green-hydrogen systems.

Why 3D-Printed Hydrogen Components Matter

• Ultra-Low Precious-Metal Loading: Ink-jet and DIW patterning reduce Pt to 0.02 mg cm-2 while boosting utilization above 16 kW g-1.

• Rapid Prototype-to-Test Cycle: CAD-to-cell in 24 h accelerates flow-field optimization without moulds or tooling.

• Monolithic Integration: All-in-one bipolar electrode (AIOBE) fuses CL/PTL/BP/gasket, slashing interfacial resistance 14×.

Innovative Design and Features

• Printing Portfolio: DIW, IJP, DLP, SLS, SLM and EBM are matched to CL (μm pores), GDL (graded porosity), PTL (ordered bubble highways) and BP (complex channels).

• Multi-Material & Multi-Scale: Core–shell nozzles co-print Ti-alloy frames with conductive polymer channels; 10 µm binder-jetting meets sub-millimeter electrolyzer tolerances.

• Low-Temperature Compatibility: <100 °C operation widens material choice to PLA, ABS, nickel and titanium alloys.

Applications and Future Outlook

• PEMFC: 3D-printed stepped flow fields lift power density to 672 mW cm-2; flexible TangoPlus plates enable bendable fuel cells for wearables.

• Electrolyzers: Gradient Ni PTL shrugs off 1 A cm-2 for 1 000 h; SLM Ti BP delivers 2 A cm-2 at 1.715 V without noble-metal substrates.

• Challenges & Opportunities: Sub-µm resolution, surface finish and long-term corrosion remain. Next targets are AI-driven inverse design, recyclable photopolymers and roll-to-roll multi-nozzle systems.

This review provides a blueprint for additive manufacturing to unlock scalable, low-cost hydrogen energy devices. Stay tuned for further advances from Prof. Wang, Prof. Yang and Prof. Zhang!

Follow the Topic

-

Nano-Micro Letters

Nano-Micro Letters is a peer-reviewed, international, interdisciplinary and open-access journal that focus on science, experiments, engineering, technologies and applications of nano- or microscale structure and system in physics, chemistry, biology, material science, and pharmacy.

Please sign in or register for FREE

If you are a registered user on Research Communities by Springer Nature, please sign in