All-Weather 3D Self-Folding Fabric for Adaptive Personal Thermoregulation

Published in Materials and Mechanical Engineering

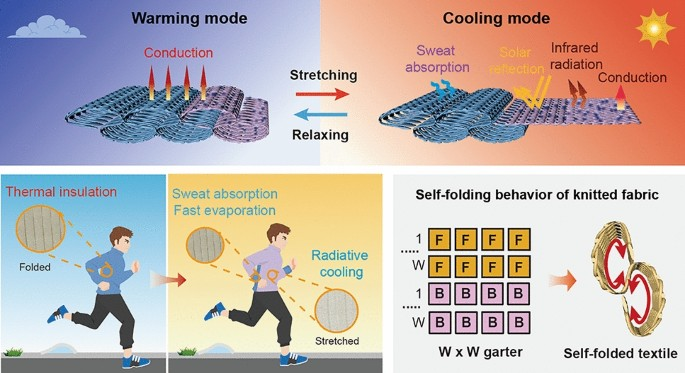

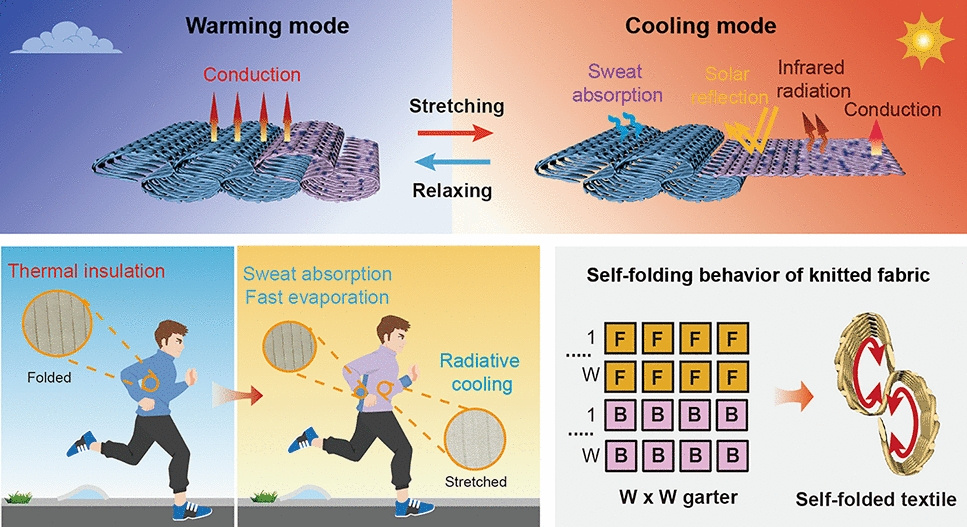

A sudden snow squall at noon, a scorching asphalt marathon, or an air-conditioned office that never quite gets the temperature right—these are the daily extremes our clothes were never built to handle. In a sweeping review published in Nano-Micro Letters, researchers from The Hong Kong Polytechnic University, led by Professor Dahua Shou, introduce a 3D self-folding knitted fabric that thinks like a thermostat. It toggles between radiative cooling and passive warming simply by stretching or relaxing, delivering year-round comfort without extra layers, without batteries, and without compromise.

Why Shape-Shifting Matters

Traditional “dual-mode” textiles either flip two layers like a reversible jacket or rely on bulky phase-change capsules. They add weight, trap sweat, and often fail halfway through a long day. The new fabric sidesteps every limitation by leveraging geometry itself. A single sheet of yarn is programmed—stitch by stitch—to curl into a 3-D accordion when relaxed, then flatten into a 2-D sheet when tugged. No hinges, no electronics, no extra seams.

Inside the Origami Thermostat

Warming Mode – 3-D Air Fortress

- Structure: 7×7 garter loops create 4–6 mm-high ridges that trap still-air cells.

- Thermal Resistance: 0627 m2 K W-1—on par with lightweight down—measured on a guarded hot-plate at 35 °C.

- Moisture Buffer: Cotton/Coolmax yarns absorb 387 % of their weight in sweat and evaporate it at 18 g h-1, beating commercial sports fabrics by 15 %.

- Micro-climate: Restricted airflow between ridges slashes convective heat loss, cutting skin-to-air heat flow by 50 % versus the flattened state.

Cooling Mode – 2-D Radiator Sheet

- Stretch & Snap: One gentle pull (≈ 2 N for 2.5 cm extension) collapses the ridges into a 1.2 mm sheet.

- Surface Chemistry: A TiO2-PDMS coating blankets the yarn. 5 % solar reflectance bounces away visible and near-IR light; 93.5 % mid-IR emissivity beams body heat through the 8–13 µm atmospheric window.

- Real-World Cooling: Under 800 W m-2 solar irradiance, arm sleeves recorded 3 °C lower skin temperature after 30 min compared with uncoated sleeves.

- Air & Vapor Flow: Even with the coating, air permeability remains 7 mL s-1 cm-2—breathable enough for marathon running.

Knitting the Future, Stitch by Stitch

- Material Palette: Ordinary cotton (structure) + Coolmax (moisture wicking) + TiO2(solar shield) + PDMS (elastic binder). All are commodity materials, keeping the cost within commercial apparel budgets.

- Machine-Friendly: Standard flat weft-knitting machines (STOLL CMS 822) produce 7×7 garter units at 7 wales cm-1—a production speed that rivals T-shirt fabric.

- Durability Marathon: 1,000 fold/relax cycles and 5 home-laundry washes later, stretch recovery is still >95 %, and TiO2loss is <1 %.

From Lab Bench to Backcountry

Prototype garments—shirts, sleeves, and full jackets—have already logged field hours in Hong Kong’s 32 °C midday sun and 15 °C mountain dawns. Volunteers reported no clammy feel, even after 4 hours of cycling, thanks to the Coolmax backbone and micro-gaps between coated yarns. The fabric’s 176 g m-2 areal mass is lighter than a standard running tee, and the transition from 3-D to 2-D can be triggered by a simple cuff tug—no zippers, no gadgets.

Next Moves

The team is now embedding humidity-sensitive yarns that automate folding in high humidity (sweat) and unfolding when dry, moving toward a hands-free climate jacket. Military, disaster-relief, and commuter markets are already in discussion, with pilot lines slated for late 2025. Long-term, the same origami-knit logic could wrap EV battery packs, drone skins, or refugee shelters—anywhere the weather refuses to stay put.

Follow the Topic

-

Nano-Micro Letters

Nano-Micro Letters is a peer-reviewed, international, interdisciplinary and open-access journal that focus on science, experiments, engineering, technologies and applications of nano- or microscale structure and system in physics, chemistry, biology, material science, and pharmacy.

Please sign in or register for FREE

If you are a registered user on Research Communities by Springer Nature, please sign in