An Integrated Modified Failure Mode Effects Analysis Shannon Entropy Combined Compromise Solution Approach to Safety Risk Assessment in Stone Crusher Unit of Ceramic Sector

Published in Earth & Environment, Mathematics, and Business & Management

This study proposes a novel Occupational Health and Safety Risk Assessment (OHSRA) model by integrating Modified Failure Mode and Effects Analysis (MFMEA), Shannon Entropy, and the Combined Compromise Solution (CoCoSo) method. The aim is to better assess and prioritize occupational hazards, addressing the inherent ambiguity and uncertainty in expert judgments during risk evaluation.

Key Components:

-

Extended Risk Criteria: The model uses five criteria instead of the traditional three: Severity (S), Occurrence (O), Detectability (D), Prevention (P), and Cost (C).

-

Shannon Entropy: Objectively determines the weights of the criteria based on data variability, reducing subjective bias.

-

CoCoSo Method: Ranks the identified hazards by aggregating multiple scoring strategies, ensuring robust and discriminative results.

-

Sensitivity Analysis: A one-at-a-time (OAT) perturbation test validates the model's stability by varying each criterion’s weight by ±0.05, ±0.10, and ±0.20.

Case Study:

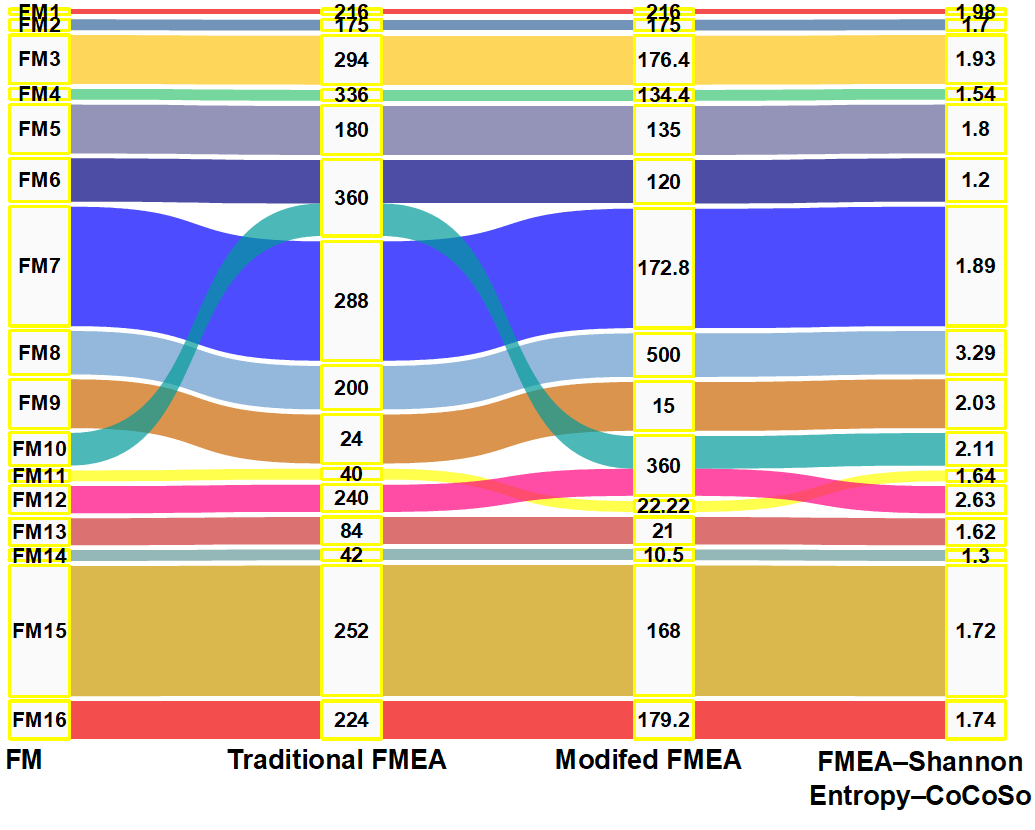

Applied to a stone crusher unit in the ceramic industry, the model identified 16 failure modes (e.g., dust exposure, noise, vibration, mechanical hazards). The integrated approach prioritized excessive dust (FM8), noise (FM12), and vibration (FM10) as the most critical risks.

Results:

-

Criterion Weights: Derived as P > D > O > C > S, highlighting the importance of preventive and detection capabilities.

-

Ranking Robustness: Sensitivity analysis showed minimal rank changes (Spearman’s ρ ≥ 0.98) under weight perturbations, confirming high stability.

-

Comparison: The MFMEA-Shannon Entropy-CoCoSo framework provided more nuanced and reliable risk prioritization compared to traditional FMEA and standalone MFMEA.

Conclusions:

The proposed framework offers a systematic, adaptable, and evidence-based approach for occupational risk assessment. It effectively handles uncertainty, supports informed decision-making, and can be scaled to other high-risk industrial sectors to enhance workplace safety and operational efficiency.

Please sign in or register for FREE

If you are a registered user on Research Communities by Springer Nature, please sign in