Binder-Free Immobilization of Photocatalyst on Membrane Surface for Efficient Photocatalytic H2O2 Production and Water Decontamination

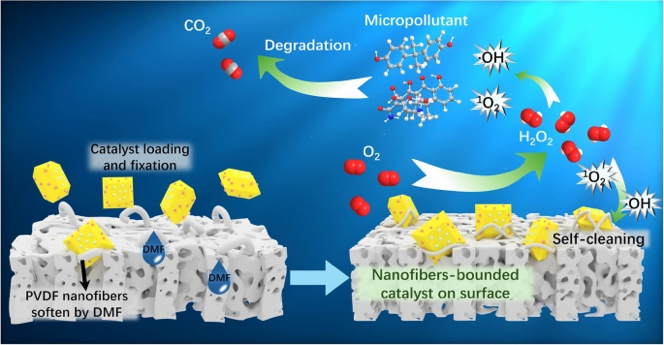

A multi-institute team led by Professors Tian Liu, Alicia Kyoungjin An and Wen-Wei Li has unveiled a binder-free “surface self-bounded photocatalytic membrane” (SSPM) that simultaneously produces green H2O2 and annihilates antibiotics in water. Published in Nano-Micro Letters, the work converts a simple PVDF nanofiber sheet into a high-activity reactor—no glue, no embedding, no energy-intensive steps.

Why Binder-Free Wins

- Instant Catalyst Fixation: A 2-minute dimethylformamide (DMF) bath softens PVDF fibers, allowing 1.6-μm CoOx/Mo:BiVO4/Pd particles to slip into freshly opened micropores; solvent evaporation then shrinks the fibers, mechanically clamping the catalyst with <5 % loss after 20 cycles.

- Mass-Transfer Leap: Surface-bound particles enjoy 4.2× faster O2 access and 19× higher H2O2 diffusion than matrix-embedded controls, pushing production to 7,700 μmol g-1 h-1—outpacing 90 % of reported catalysts.

- Hydrophobic Shield: The 120.9° water-contact-angle surface limits H2O2 back-decomposition, yielding 0.53 mM in 2 h versus 0.12 mM for embedded designs.

- Universal Toolkit: The same stretch-shrink protocol immobilized 800 nm RF523 spheres and hydrophilic variants, cutting fabrication cost by 39 %.

Real-World Validation

- Micropollutant Blitz: Under 254 nm UV (1.08 mW cm-2), the membrane erased 95 % of 10 mg L-1 tetracycline or bisphenol A in 60 min—10× faster than UV alone—while mineralizing 70 % of total organic carbon.

- Lake-to-Tap Resilience: Tests on lake water, tap water and secondary effluent all exceeded 90 % pollutant removal, with negligible activity loss in 5 mM Cl-, NO3- or humic acid.

- Continuous-Flow Ready: A flow-by reactor (0.2 mL min-1) sustained 82 % tetracycline and 93 % BPA removal for 10 h with self-cleaning antifouling action.

Mechanistic Insights

- Multi-Physics Modeling: Oxygen concentration profiles show severe starvation inside embedded catalyst layers, whereas SSPM maintains >0.8 mM O2 at the surface—critical for sustaining the 2-electron O2 reduction pathway.

- ROS Mapping: Scavenger tests reveal ·OH and 1O2 dominate degradation; LC-MS identified 10 BPA and 9 TC intermediates, all eventually mineralized to CO2 and H2O.

- Self-Defouling: In situ H2O2 continuously oxidizes membrane foulants, maintaining 95 % flux after 40 h of operation.

Economic & Regulatory Edge

- Cost Model: At 10,000 m2 yr-1 production, SSPM is projected at $9.95 m-2—39 % cheaper than matrix-embedded equivalents and competitive with commercial PVDF.

- Dry-Storage Advantage: Unlike embedded membranes that lose 40 % activity after 30 days dry storage, SSPM retains >95 % performance, simplifying logistics.

- Regulatory Alignment: All materials are REACH-compliant, and the process uses only DMF and ethanol—solvents already approved for membrane manufacturing.

Scale-Up & Next Steps

- Roll-to-Roll Pilot: A 1 m2 module under construction will integrate SSPM into a skid-mounted UV/H2O2 reactor for 10 m3 day-1 municipal pilot trials in Suzhou.

- Hybrid AOPs: Coupling SSPM with low-pressure UV lamps enables on-site H2O2 generation + micropollutant destruction, eliminating chemical dosing and storage hazards.

- Beyond Water: The stretch-shrink concept is being adapted for gas-phase VOC filters and self-sterilizing air-conditioning meshes.

By transforming passive membranes into active, self-armored reactors, the Li team delivers a plug-and-play upgrade for next-generation UV/H2O2 plants—cleaner water, lower cost, zero binders.

Follow the Topic

-

Nano-Micro Letters

Nano-Micro Letters is a peer-reviewed, international, interdisciplinary and open-access journal that focus on science, experiments, engineering, technologies and applications of nano- or microscale structure and system in physics, chemistry, biology, material science, and pharmacy.

Please sign in or register for FREE

If you are a registered user on Research Communities by Springer Nature, please sign in