Combustion-Assisted Low-Temperature ZrO2/SnO2 Films for High-Performance Flexible Thin Film Transistors

Published in Electrical & Electronic Engineering

Solution-based sol-gel technology has attracted interest in various fields due to the accessibility of advanced materials with ‘tailor-made’ functionalities through inexpensive and environmentally viable processing routes. One of the reasons for the continued advancement of sol-gel technology is the ease of control of the nano-architecture of the resultant materials and the plethora of different material constructs that can be developed. The method’s versatility lies in the comfort of integrating sol-gel technologies with other forms of processing, allowing multidisciplinary approaches to occur with minimal effort.

Hence, many efforts have been made to apply SnO2 and/or ZrO2 by sol-gel processing to maximize each other’s advantages. However, there is a critical issue that needs to be addressed to practically utilize these solution-based technologies. A considerable amount of energy is required to convert the precursor into an oxide film and sufficiently remove internal organic residues, and for this, high-temperature annealing of >400 °C is usually accompanied incompatible with most flexible plastic substrates after precursor deposition. However, there are still challenges in implementing solution-based low-temperature processes so far.

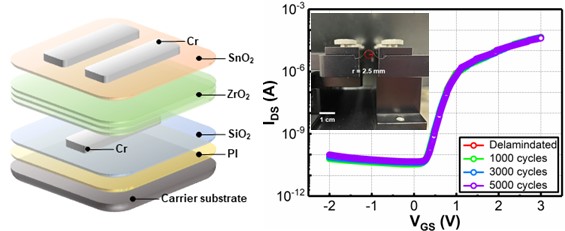

(2) Also, due to the synergistic chemical stability between ZrO2 and SnO2, high-performance electrical properties have been achieved (please refer to our Supplementary Table 4, which compares the characteristics with previous studies): a field-effect mobility of 26.16 cm2/Vs, a subthreshold swing of 0.125 V/dec, and an on/off current ratio of 1.13 × 106 at a low operating voltage of 3 V. Zr4+ (760 kJ/mol) demonstrate stronger bonding with oxygen compared to others (e.g. Al3+ (511 kJ/mol)), which allows for the formation of more complete metal-oxygen bonds and enables a reduction in interface trap sites between the insulator and the semiconductor.

(3) Moreover, we demonstrated flexible ZrO2/SnO2 TFTs with strong mechanical stability, enduring 5,000 bending cycles at a <2.5 mm radius by reducing device dimensions.

(4) In addition to electrical and mechanical properties, we investigated the chemical and material characteristics more clearly and in-depth through various analyses. we determined the temperature at which the precursors are converted to oxides by thermogravimetric analysis (TGA) and differential scanning calorimetry (DSC). Also, the structural properties of SnO2 and ZrO2 films were investigated by grazing incidence X-ray diffraction (GIXRD) and X-ray photoelectron spectroscopy (XPS).

The aforementioned results suggest that the combustion-assisted solution process enables the fabrication of high-performance flexible ZrO2/SnO2 TFTs with relatively low process temperatures and that it is a suitable process for the full implementation of solution-processed metal oxide electronics and flexible electronics where high-temperature processes should be avoided as well.

Follow the Topic

-

npj Flexible Electronics

This journal publishes high-quality papers related to flexible electronic systems, including plastic electronics and emerging materials, new device design and fabrication technologies, and applications.

Related Collections

With Collections, you can get published faster and increase your visibility.

Neuromorphic Circuits and Bio-inspired Systems

Publishing Model: Open Access

Deadline: Mar 31, 2026

Living and Biomaterials based Sustainable Flexible Electronics

Publishing Model: Open Access

Deadline: Aug 24, 2026

Please sign in or register for FREE

If you are a registered user on Research Communities by Springer Nature, please sign in