Conducting Polymer Hydrogel for All-Hydrogel Bioelectronics

Published in Electrical & Electronic Engineering

Vision of Hydrogel Bioelectronics

Biological tissues, especially electrically active tissues and organs (muscle, heart, nerve, spinal cord, brain) are soft and wet materials. However, most of the conventional bioelectronic implants for these tissues have been made of, at least in part, engineering materials that are starkly dissimilar with much higher stiffness and low to no water contents. Furthermore, conventional metallic electrodes are electronic conductors whereas biological tissues are ionic conductors, making their electronic-ionic interfaces often exhibit poor electrical and electrochemical performance (high impedance, low charge injection capacity, etc). As we discussed in our review (Hydrogel bioelectronics, Chemical Society Reviews 48, 1642-1667 (2019)), bioelectronics made out of tissue-like hydrogels offers a promising alternative to address these lingering challenges. However, as all futuristic visions typically are, there were many outstanding challenges to bringing the vision of hydrogel bioelectronics to the real world, especially around novel materials that can satisfy a set of unmet needs in necessary properties.

Searching for Better Conducting Polymer Hydrogels

Owing to their unique combination of tissue-like mechanical properties, high water contents, and coexistence of electronic and ionic conductivity, conducting polymer hydrogels have been one of the most promising classes of materials for hydrogel bioelectronics. However, most existing conducting polymer hydrogels could only provide limited electrical and mechanical properties, often not compatible with various advanced manufacturing techniques necessary for the fabrication of functional devices, when we first explored the problem years ago.

We initially focused on improving the electrical properties of conducting polymer hydrogels. We closely reviewed the previously developed conducting polymer hydrogels to find a new strategy. We found that most existing conducting polymer hydrogels were prepared by compositing non-conductive hydrogel networks with conducting polymers to provide mechanical integrity and robustness, which in turn substantially trade-off electrical properties of the resultant composite conducting polymer hydrogels. Inspired by this observation, we proposed the pure PEDOT:PSS hydrogels with superior electrical properties by eliminating non-conductive additives in conducting polymer hydrogels while maintaining mechanical integrity and stability in wet physiological environments (Pure PEDOT:PSS hydrogels, Nature Communications 10, 1043 (2019)). The resultant pure PEDOT:PSS hydrogels achieved over 20 S cm-1electrical conductivity (one of the highest at that time), tissue-like softness and water contents, and moderate stretchability (~35% strain) while consisting of 100% conducting polymers. Encouraged by this development, we further introduced 3D printability to conducting polymer hydrogels to enable facile, flexible, and programmable fabrication of high-resolution bioelectronic devices (3D printing of conducting polymers, Nature Communications 11, 1604 (2020)).

However, after our initial works were reproduced and used by colleagues in the field, we learned feedback that the mechanical properties of pure PEDOT:PSS hydrogels, especially stretchability and fracture toughness, were insufficient for many bioelectronic applications to provide necessary mechanical integrity and robustness in highly dynamic physiological environments. This feedback made us think about possible ways to improve mechanical properties while keeping favorable electrical properties that we could achieve.

Returning To Composite Hydrogel: How to Solve Trade-Off?

After trying numerous methods over 6 months, we started to question ourselves that pure conducting polymer hydrogels might not be the ideal approach to achieve both superior electrical and mechanical properties. Ironically, we circled back to a composite strategy (mixing non-conductive and conductive polymers to construct hydrogels) and started to think about how to solve the trade-off between mechanical and electrical properties in composite conducting polymer hydrogels.

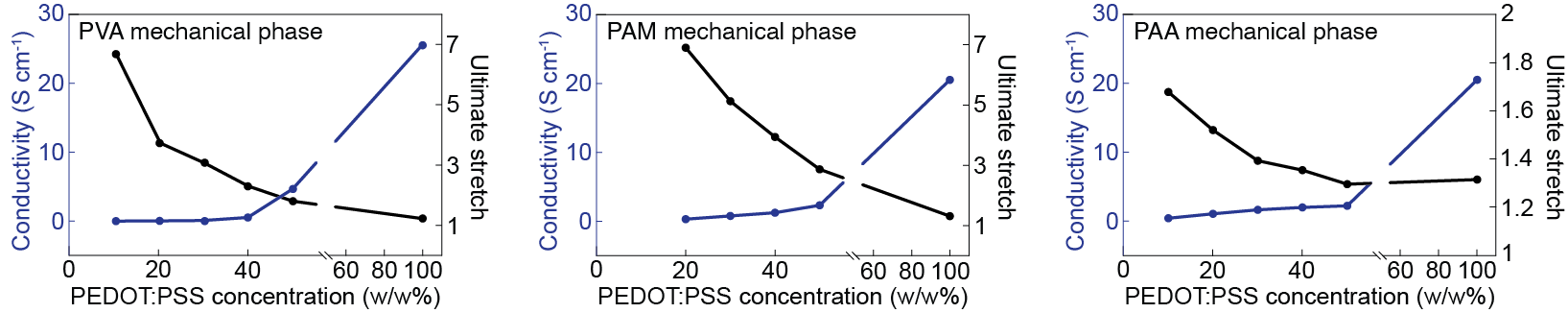

In conventional composite conducting polymer hydrogels, various hydrophilic polymers (typically used to form hydrogels) such as polyvinyl alcohol (PVA), polyacrylamide (PAM), and polyacrylic acid (PAA) are mixed with conducting polymers to act as mechanically reinforcing elements. In such conventional composite conducting polymer hydrogels, the resultant hydrogels exhibit a substantial trade-off between mechanical and electrical properties, rendering them unfavorable to bioelectronic applications where both good electrical and mechanical properties are required. With careful examination of the microstructure of these conventional conducting polymer hydrogels using AFM phase imaging, we found a uniform distribution of conducting polymers in the non-conducting polymer matrix in composite hydrogels which may cause poor connectivity of each domain hindering either mechanical or electrical properties (depending on the dominant phase) of composite hydrogels.

Bi-Continuous Conducting Polymer Hydrogel

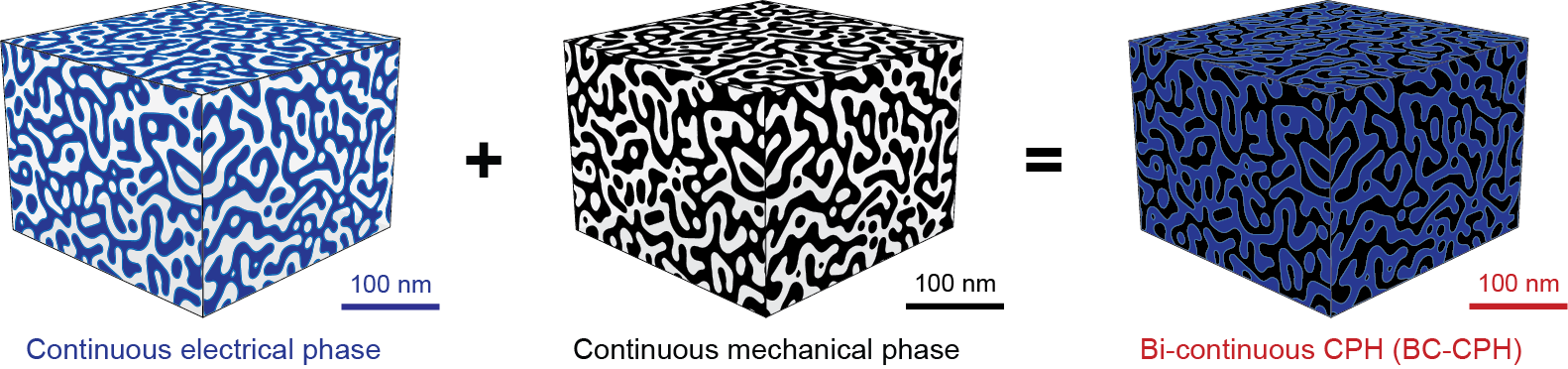

The observations from the conventional composite conducting polymer hydrogels gave us a better understanding of the challenge – poor connectivity of mechanical and electrical phases in composite hydrogels. As the target problem became clearer, we started to have a hint of the solution – how about introducing phase-separation in the precursor of conducting polymer hydrogels to improve the connectivity of each phase instead of uniform mixing? Such phase-separated electrical and mechanical phases in the precursor (or ink) may act as a ‘pre-formed’ network of each phase to allow the preparation of a bi-continuous conducting polymer hydrogel (BC-CPH), where electrical and mechanical phases are continuous, maintaining high connectivity and corresponding favorable properties without substantial trade-off.

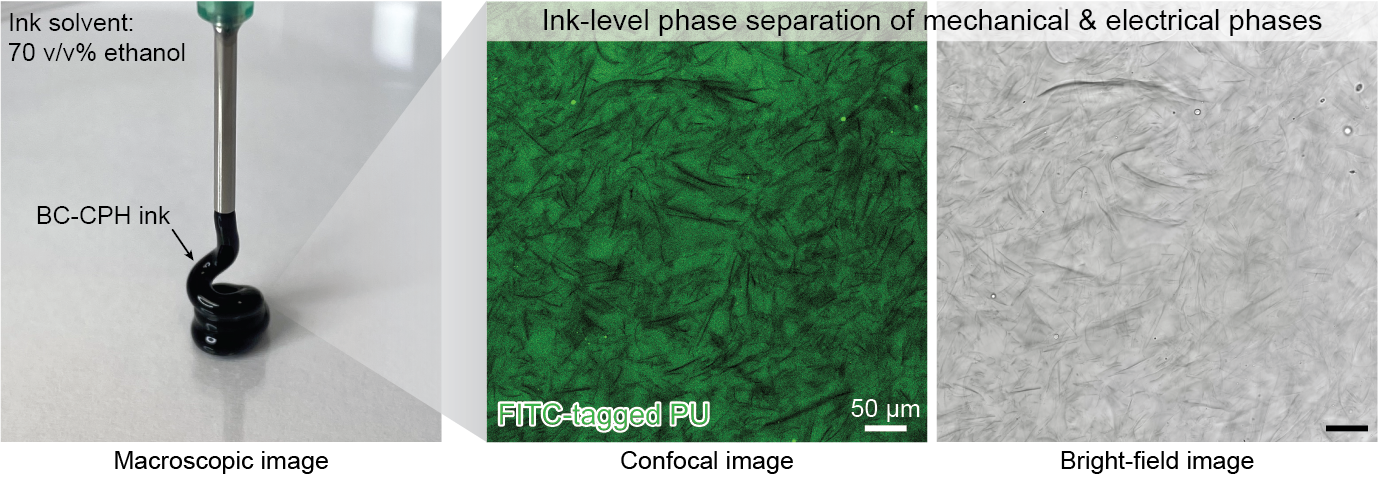

We were excited about this idea, but implementing the idea into the actual materials system was a less trivial task. We wanted to keep PEDOT:PSS as an electrical phase due to its favorable electrical properties, stability in wet physiological environments, and ready commercial-availability in high quality and performance. However, the choice of mechanical phase was not easy. To realize our materials design, the mechanical phase should satisfy (i) the capability to form moderate but not excessive phase-separation with PEDOT:PSS phase, (ii) stability in wet physiological environments, (iii) biocompatibility, (iv) high water contents, and (v) favorable mechanical properties such as low Young’s modulus, high stretchability, and high fracture toughness. After numerous trials, we found that hydrophilic polyurethane dissolved in ethanol-water co-solvent satisfied all of the requirements. The resultant BC-CPH ink showed a well-developed moderate phase-separation of electrical (PEDOT:PSS) and mechanical (hydrophilic polyurethane) phases in 70 % ethanol solution. Interestingly, the phase-separation provided favorable rheological properties to the BC-CPH ink that is readily-compatible with various advanced manufacturing techniques such as multi-material 3D printing by direct ink writing.

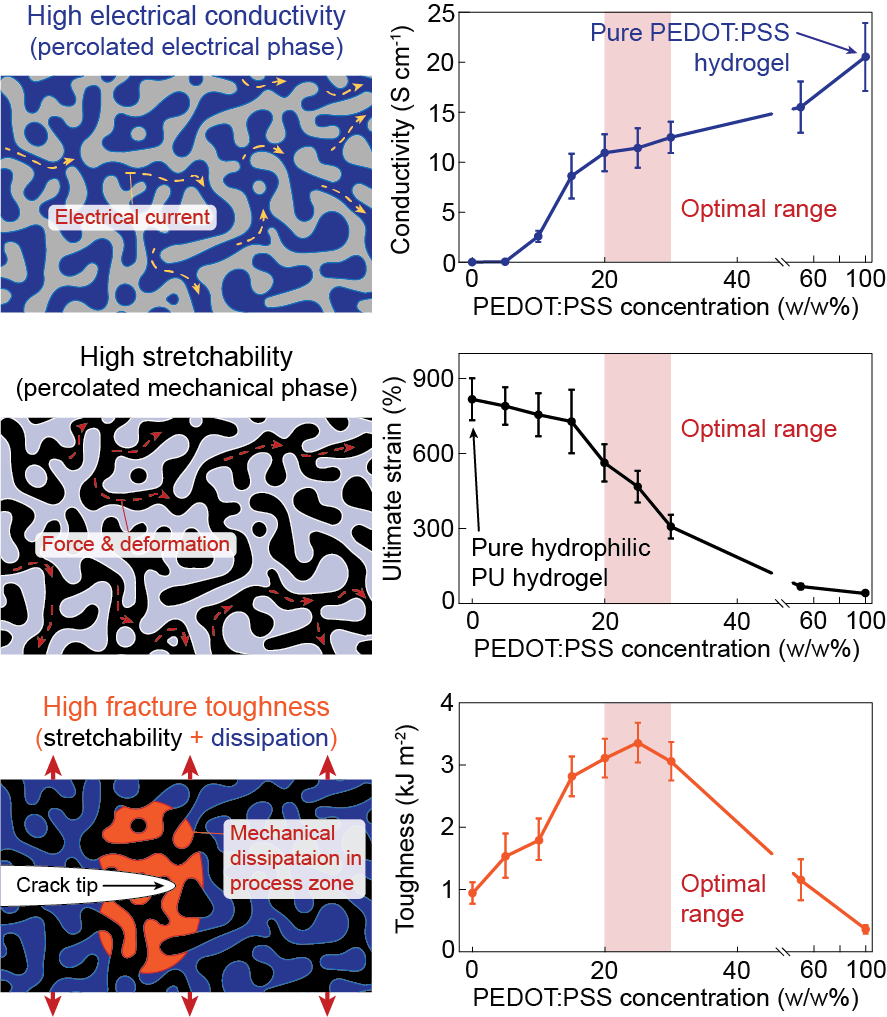

The BC-CPH could be readily prepared by simply evaporating the non-toxic solvent (ethanol and water) from the printed BC-CPH ink followed by swelling in wet environments. After systematically characterizing a range of compositions, we found that the BC-CPH with around 20-30 w/w% PEDOT:PSS to hydrophilic polyurethane showed the optimal balance between electrical and mechanical properties, achieving a remarkable electrical conductivity over 11 S cm-1 and stretchability over 400% strain simultaneously. To our surprise, the fracture toughness of BC-CPH showed the highest value around the optimal composition with over 3,300 J m-2. We realized that the bi-continuous microstructure between highly stretchable mechanical phase (hydrophilic polyurethane hydrogel) and less stretchable electrical phase (PEDOT:PSS hydrogel) render the BC-CPH acting like double-network tough hydrogels, endowing it high fracture toughness via a synergistic combination of high stretchability and mechanical dissipation. As we have worked on tough hydrogels over many years, this was a particularly intellectually amusing discovery!

All-Hydrogel Bioelectronics

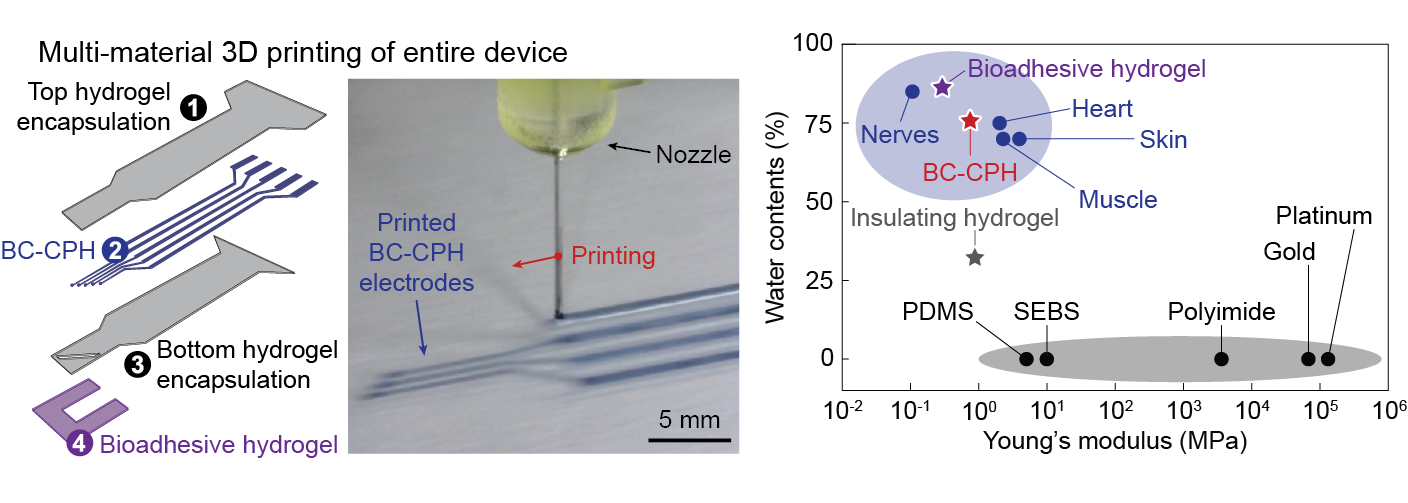

Taking advantage of the 3D printability of the BC-CPH, together with bioadhesive and insulating hydrogel inks, we demonstrated a facile multi-material 3D printing of all-hydrogel bioelectronics in the form of a monolithic hydrogel construct capable of electrophysiological sensing and stimulation. The resultant all-hydrogel bioelectronic devices showed tissue-like softness and water contents with high mechanical and electrical stability and performance in wet physiological environments. To our knowledge, this was one of the first demonstrations of monolithic all-hydrogel bioelectronics readily manufacturable via 3D printing, and we were really excited while making and testing these samples.

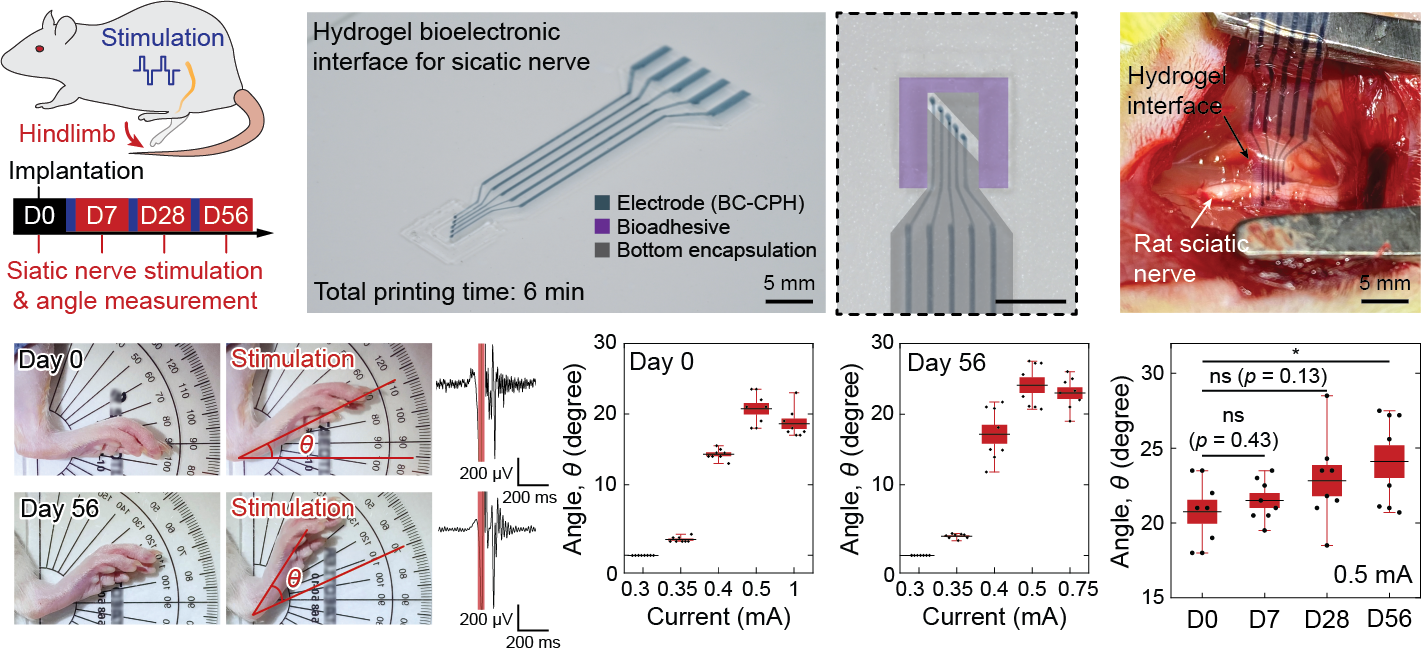

To evaluate the all-hydrogel bioelectronics for electrophysiological applications, we performed a set of in vivo studies for biocompatibility and long-term electrophysiological recording and stimulation efficacy. The in vivo biocompatibility studies revealed that the all-hydrogel bioelectronics elicited significantly lower immune responses compared to conventional elastomeric bioelectronic devices owing to their tissue-like properties and composition. The all-hydrogel bioelectronics could provide continuous long-term recording (heart) or stimulation (sciatic nerve, spinal cord) over 2 months in rat models. Notably, the recording and stimulation efficacy increased after the initial implantation contrary to decreasing efficacy in conventional bioelectronic implants. This unique and highly favorable characteristic of the all-hydrogel bioelectronics may originate from their tissue-like properties and subsequent favorable tissue-implant interactions as we previously observed in hydrogel hybrid neural probes (Adaptive and multifunctional hydrogel hybrid probes for long-term sensing and modulation of neural activity, Nature Communications 12, 3435 (2021)).

Outlook

The various unique features of the BC-CPH and the all-hydrogel bioelectronics make us really excited about the potential benefits they can bring to the field of bioelectronics including (i) simultaneously achieving highly favorable electrical and mechanical properties, (ii) tissue-like mechanical properties and water contents, (iii) superior stability and biocompatibility in wet physiological environments, (iv) ready-compatibility to various advanced manufacturing techniques such as 3D multi-material printing, and (v) highly reproducible preparation method based on readily commercially-available materials. We hope that this work would become a powerful new tool for researchers in the field of bioelectronics and beyond.

For more details, check out our paper “3D printable high performance conducting polymer hydrogel for all-hydrogel bioelectronic interfaces” on Nature Materials.

Follow the Topic

-

Nature Materials

A monthly multi-disciplinary journal that brings together cutting-edge research across the entire spectrum of materials science and engineering, including applied and fundamental aspects of the synthesis/processing, structure/composition, properties and performance of materials.

Please sign in or register for FREE

If you are a registered user on Research Communities by Springer Nature, please sign in