Designing a new blueprint for closing and decarbonizing China’s bulk material cycles

Published in Sustainability

Designed by Svetlana Lezina@Metabolic

The urgent need to embrace circular economy in China’s bulk material cycles

Circular economy (CE) is not a novel concept, but its relevance has been underscored in contemporary discourse owing to the pressing need to address an array of challenges, notably climate change, waste management, and resource scarcity. It hinges on the principle of prolonging the life cycle of materials within the economy, achieved through strategies such as using less, using longer, and using again. The urgency to expedite the transition towards CE has grown exponentially, particularly in light of the United Nations Environment Programme’s projection that global material use will double by 2060 and the Circularity Gap Report’s evaluation that the world’s circularity has shrunk from 9.1% to 7.2% of total material inputs in the past five years. As such, the pursuit of CE appears to be a promising solution to reduce our environmental footprint and create a more sustainable future through using less, using longer, making clean, and using again.

China, often regarded as a forerunner in the CE, presents a prime experimental ground for assessing the capacity of CE strategies to facilitate substantial emissions reduction. The efforts made by China to decarbonize its economy carry significant implications on a global scale. By quantitatively assessing the decarbonization potential inherent in CE strategies and examining avenues for their practical implementation, China can significantly curtail its own carbon footprint. Moreover, it can stand as an exemplar for other nations striving to combat climate change. This role takes on heightened importance in light of China’s climate ambitions and its sustained commitment to sustainable development. As China strives to achieve carbon neutrality by 2060, it is crucial to fully comprehend the potential and challenges associated with CE strategies.

Key considerations for implementing CE in China’s bulk material cycles

Despite widespread endorsement, the effective implementation of CE, especially in bulk material cycles, has been limited and remains fragile. In practice, we often overlook the following critical factors.

- Limited emission reduction potential of recycling. It must be acknowledged that achieving 100% recycling of end-of-life materials is often technically infeasible, especially for critical metals and composite materials. The scaling up of new recycling technologies that align with existing political, economic, and commercial conditions can be challenging. Furthermore, the energy demands associated with waste handling and recycling processes can be substantial. Additionally, it is essential to recognize that recyclable materials undergo degradation during reproduction, necessitating additional inputs of raw materials.

- Neglecting demand reduction. Demand reduction is often given inadequate attention, yet it holds immense potential within the CE framework. This strategy directly addresses the root causes of unsustainable consumption patterns and contributes to the establishment of a more sustainable economy in the long term. Demand reduction, although currently undervalued, has a significant capacity to mitigate environmental impacts, particularly for materials lacking a viable recycling loop.

- Variability in CE implementation. The ability to effectively implement CE strategies varies depending on multiple factors. It is crucial to carefully consider the timing, optimal strategies, and specific targets for CE adoption. Timing is of the essence, as not all countries or cities possess the potential or adequate infrastructure to facilitate a seamless CE transition. Developed countries or urban centers often exhibit higher per capita material stock in use, resulting in more significant reserves of recyclable materials to support CE practices. Additionally, it is imperative to refrain from generalizing CE strategies across all materials and products. Different materials may require tailored approaches; for example, materials like glass, while theoretically infinitely recyclable, may not yield significant emission reductions through recycling compared to alternative strategies.

Implications of closing China’s bulk material cycles

Bulk materials have played a pivotal role in modern society, elevating living standards, creating employment opportunities, and enabling mobility and communication. However, the production and use of bulk materials have exacted a substantial environmental toll. The production and use of bulk materials heavily relies on the extraction of finite and polluting fossil fuels as a primary energy source, alongside the depletion of natural minerals. It is a sobering fact that approximately 70% of global greenhouse gas (GHG) emissions can be attributed to the production and use of materials. Failure to take immediate action to revolutionize the production and use of bulk materials could prove catastrophic, as the surging demand for housing and infrastructure is expected to further escalate global requirements, thereby undermining ambitious climate goals.

Therefore, we have devised an integrated modeling framework named IMAGINE Materials. This framework systematically investigates the feasibility of establishing a closed-loop system encompassing 13 bulk materials, including cement, steel, aluminum, copper, rubber, plastic, glass, lime, asphalt, sand, gravel, brick, and wood. IMAGINE Materials serves as a means to delineate and evaluate the decarbonization potential inherent in various CE strategies within China. The temporal scope of our analysis spans from 2019 to 2060. We find that:

- When: China has the potential to meet a significant portion of its bulk material demand through recycling by the year 2060. However, the optimal timing for promoting CE strategies may vary among different regions within China.

- Where: Less-developed regions can benefit from the experiences and practices of early adopters in more-developed regions as they prepare to implement CE strategies.

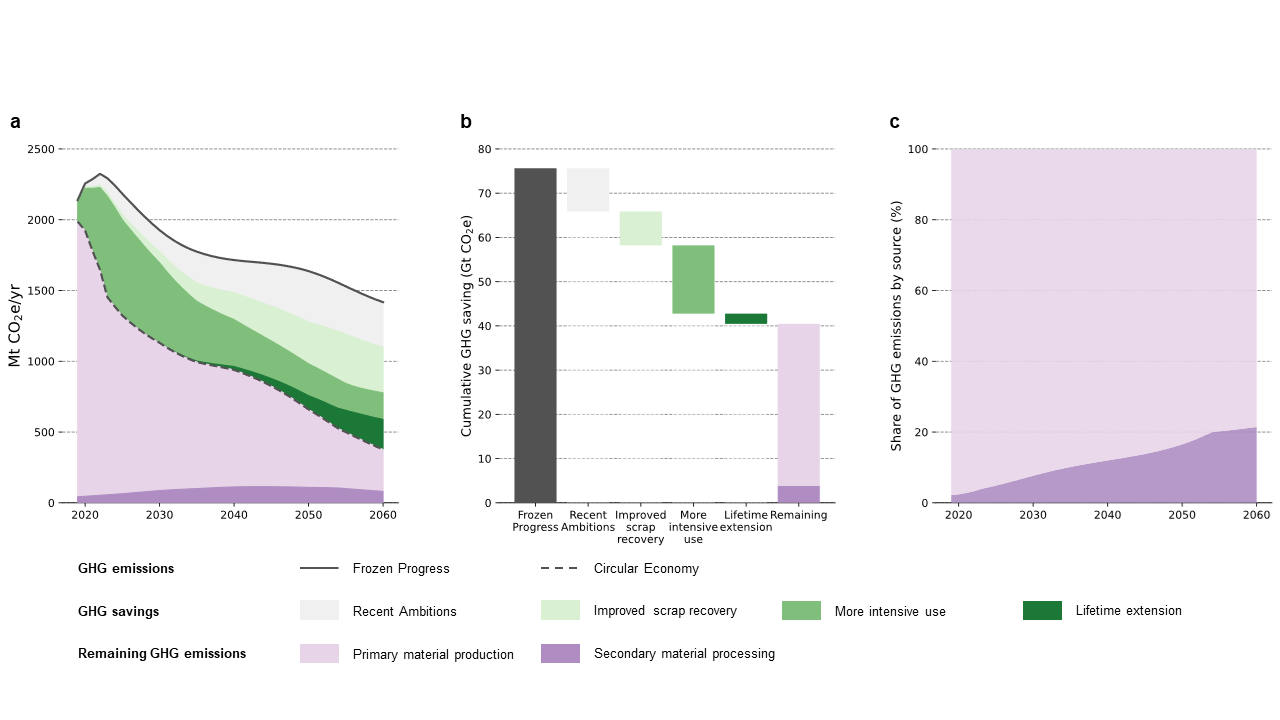

- How much: While improved scrap recovery can contribute to a 10% reduction in GHG emissions from the bulk materials system between the present and 2060, achieving a more intensive use of materials resulting in reduced demand could lead to a substantially greater reduction of 21%. In contrast, extending the lifetime of materials, while beneficial, is associated with a relatively modest impact, yielding only a 3% reduction in emissions.

- Which: The potential for mitigating GHG emissions through material recycling is most prominent for metals. In contrast, for the majority of non-metallic materials such as cement, plastics, and glass, strategies involving more intensive use and lifetime extension may hold greater promise in terms of GHG reduction.

In summary, pursuing CE opens up new opportunities for achieving net-zero emissions, serving as an important alternative in the event that production-side technologies do not materialize in a timely manner. Our study underscores the importance for policymakers to broaden their focus beyond merely improving the recycling rates of scrap. It is equally imperative to accord due attention to strategies aimed at extending product lifetimes and more intensive use.

Figure 1 | GHG savings by three CE strategies and remaining GHG emissions. (a) Annual GHG savings by three CE strategies and remaining GHG emissions from 2019 to 2060. (b) Cumulative GHG savings by three strategies and remaining GHG emissions from 2019 and 2060. (c) Breakdown of remaining GHG emissions by source between 2019 and 2060. Solid lines represent the GHG emissions in the FP scenario.

Concluding remarks

Our study provides a comprehensive overview of intricate provincial material dynamics, shedding light on the prospects and obstacles associated with CE strategies across various materials and regions. Collaborative endeavors aimed at improving scrap recovery and curbing our appetite for primary materials present significant avenues for achieving decarbonization goals.

This research has been published in Nature Climate Change and is available online (https://doi.org/10.1038/s41558-023-01782-6). The associated Research Briefing article is available online (https://www.nature.com/articles/s41558-023-01799-x). All data and code associated with the research are available at http://doi.org/10.6084/m9.figshare.21837195.

Follow the Topic

-

Nature Climate Change

A monthly journal dedicated to publishing the most significant and cutting-edge research on the nature, underlying causes or impacts of global climate change and its implications for the economy, policy and the world at large.

What are SDG Topics?

An introduction to Sustainable Development Goals (SDGs) Topics and their role in highlighting sustainable development research.

Continue reading announcement

Please sign in or register for FREE

If you are a registered user on Research Communities by Springer Nature, please sign in