Designing Amino Functionalized Titanium-Organic Framework on Separators Toward Sieving and Redistribution of Polysulfides in Lithium-Sulfur Batteries

Published in Materials

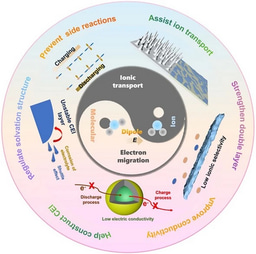

Lithium–sulfur batteries (LSBs) are poised to reshape energy storage with their ultra-high theoretical capacity (1675 mAh g-1) and energy density (2800 Wh kg-1). Yet, the notorious “polysulfide shuttle” continues to erode cycle life and slash sulfur utilization. Now, researchers from the State Key Laboratory of Advanced Processing and Recycling of Non-Ferrous Metals at Lanzhou University, led by Professor Fen Ran, unveil a precision separator coating that turns the old problem into a new advantage. Their work, reported in Nano-Micro Letters, delivers a sub-nanometer ionic gate that not only blocks polysulfides but also re-uses them.

Why This MOF Coating Matters

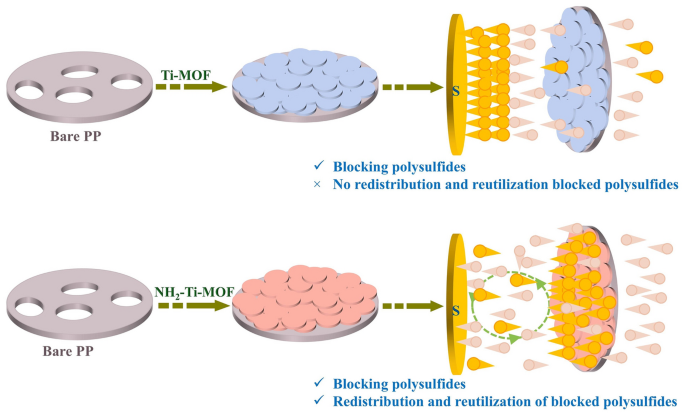

- Sub-nanometer precision gate: The –NH2 functional group shrinks Ti–MOF pore size from 0.95–1.10 nm to a uniform 0.83 nm—exactly the “sweet spot” that sieves out long-chain polysulfides while letting solvated Li+ slip through unhindered.

- Electrostatic recycling station: Positively charged –NH2 moieties act as a dynamic depot, adsorbing escaped polysulfides via electrostatic attraction, then releasing them back to the cathode during charge—boosting active-material utilization and extending cycle life.

- Lewis acid–base fast lanes: Nitrogen lone-pairs form transient Li+–N coordination bonds, lowering desolvation energy and guiding directional Li+ transport, cutting polarization to 0.15 V at 0.1 C.

Engineering the Functional Separator

- One-step solvothermal synthesis of NH2–Ti–MOF nanocakes (~200 nm) followed by low-temperature activation (250 °C, N2) to open micropores without collapse.

- Doctor-blade coating onto commercial Celgard® 2500 yields a dense 9-μm layer (0.37–0.50 mg cm-2) that withstands 180 °C thermal abuse and retains structural integrity even after 1003 cycles.

- Coin-cell validation with Ketjenblack/S cathodes (0.84–1.0 mg cm-2 S) shows an ultralow capacity fade of 0.045 % per cycle over 1 000 cycles at 1 C—outperforming bare PP (0.073 %) and Ti–MOF-only (0.056 %) controls.

Characterizing the Nano-Gate

- Visual shuttle test: In an H-cell, a 0.83 nm NH2–Ti–MOF membrane keeps Li2S6 solution colorless for 24 h, while PP and Ti–MOF separators show visible yellowing—direct evidence of suppressed crossover.

- In-situ Raman mapping: After discharge to 1.7 V, separator-facing Li anode surfaces reveal zeropolysulfide signatures for NH2–Ti–MOF, versus strong S62- peaks for PP.

- DFT & MD calculations: Adsorption energies for Li2S4, Li2S6, and Li2S8 on –NH2 sites jump by 0.3–0.5 eV compared to pristine Ti–MOF, while MD shows a 150.8 kJ mol-1 diffusion barrier for S62- through 0.83 nm pores.

Future Outlook

- Scalable roll-to-roll coating: The cake-like morphology and benign aqueous/methanol processing route promise compatibility with industry-scale separator production lines.

- High-loading cathodes: Preliminary tests at 3.0 mg cm-² sulfur still deliver 403.7 mAh g-1after 153 cycles, indicating robustness under practical areal capacities.

- Next-gen chemistries: The same gating concept can be extended to Na–S, K–S, or even solid-state systems by tuning pore size and surface functionality.

With a single, elegantly engineered layer, the Lanzhou team transforms the separator from passive barrier to active polysulfide gatekeeper—ushering lithium–sulfur batteries toward real-world, long-lifetime deployment.

Follow the Topic

-

Nano-Micro Letters

Nano-Micro Letters is a peer-reviewed, international, interdisciplinary and open-access journal that focus on science, experiments, engineering, technologies and applications of nano- or microscale structure and system in physics, chemistry, biology, material science, and pharmacy.

Please sign in or register for FREE

If you are a registered user on Research Communities by Springer Nature, please sign in