Disclosing degradation mechanism in sustainable solders

Published in Materials

In the microelectronics and power semiconductor industry reliable electrical connections display a crucial topic. Solder balls are in general utilized to provide the electrical contact between the chip package and print circuit board (PCB). The intactness of such solder balls is crucial for the device in terms of lifetime and functionality. In order to provide an improved sustainable technology in this context, the fundamental understanding of degradation mechanisms, in particular of Pb-free solders is important, however remains a vital challenge in the field of materials science.

Due to growing health and environmental concerns, more sustainable connections are essential. Hence, tin (Sn‑) based solder alloys have largely replaced lead‑based alloys in power‑ and microelectronics. Here, Sn – 3.0 wt.% Ag – 0.5 wt.% Cu (SAC305) is one of the most promising Sn‑based solder alloys. Nevertheless, conventional SAC solder balls can already exhibit microstructural degradation in the as‑reflowed condition.

A problem solver in this context is the chemical element Bismuth (Bi). The use of Bi as an alloying element shows great potential to diminish microstructural degradation and to prolong the long-term fatigue stability of SAC solder balls. In this context a deep understanding of the underlying mechanism triggering thermo-mechanical instabilities is essential.

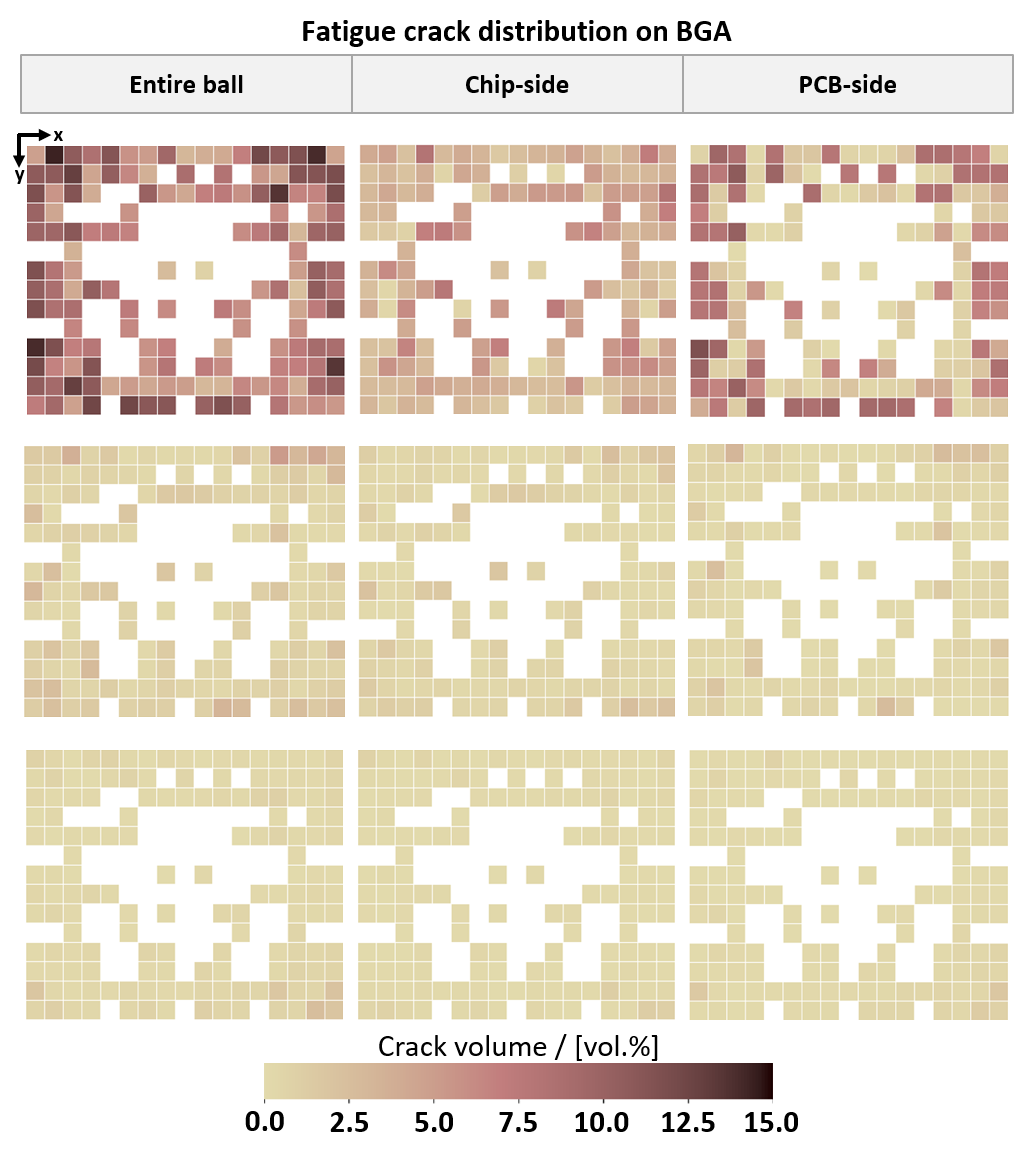

A crucial component for the assessment of the relation between microstructural degradation and functionality is the need of statistical information. That is, the characterization of each solder ball volume on the so-called ball grid array (BGA).

Here, it is essential that the studies are not constrained to machine learning (ML)-based image segmentation alone but also to consider the underlying mechanisms for defect‑formation and correlations with microstructural and mechanical phenomena in the material. In particular, the implications for fatigue crack initiation by the segmented flux pores have not yet been considered. That is, the connection between ML‑based image segmentation and materials science has not yet been made.

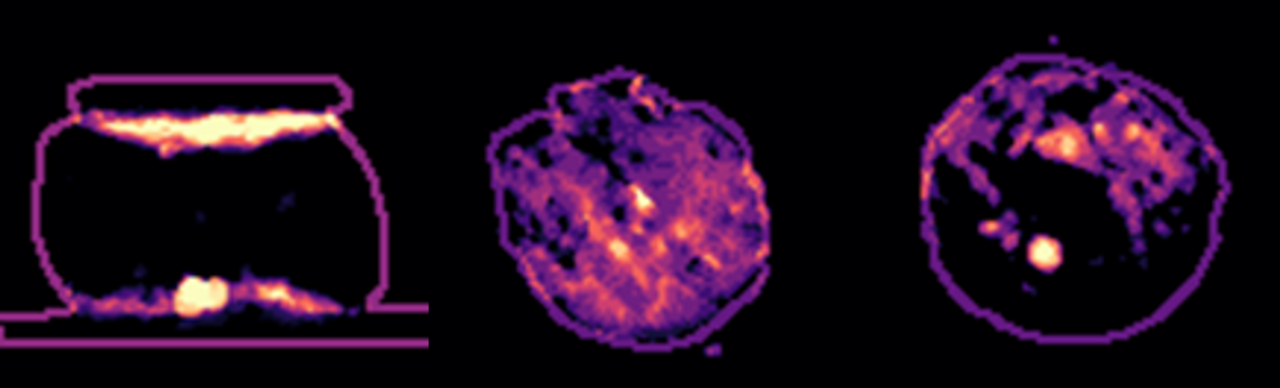

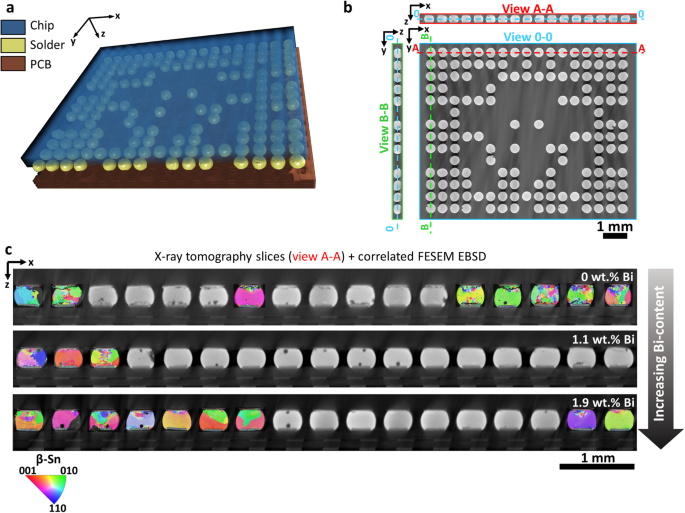

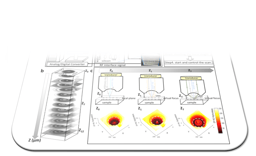

The Materials Center Forschung GmbH, supported by Infineon Technologies AG and the Kompetenzzentrum für Automobil- und Industrietechnik developed within the COMET framework (K2 Center IC-MPPE, Project No. 886385) a workflow, utilizing 3D non‑destructive X‑ray tomography, field emission scanning electron microscopy (FESEM) combined with electron backscatter diffraction (EBSD), finite element method modeling and specifically a machine learning (ML‑) algorithms to statistically investigate crack initiation and propagation in SAC305‑Bi solder balls upon thermal cycling on board (TCoB).

The results uncover that intergranular fatigue cracking is the predominant failure mechanism during TCoB and that dynamic recrystallisation precedes crack initiation. The team found that fatigue cracks are specifically initiated at surface notches, flux pores and printed circuit board‑metallisation intrusions.

The work links the aspects of big‑data analysis with ML‑algorithms and provides an in‑depth understanding about the underlying materials science. It provides essential insights regarding the underlying microstructural and mechanical mechanisms for recrystallisation and cracking, enabling the further improvement of existing technologies.

A link to the manuscript can be found here: Correlative, ML-based and non-destructive 3D-analysis of intergranular fatigue cracking in SAC305-Bi solder balls | npj Materials Degradation (nature.com)

Follow the Topic

-

npj Materials Degradation

This journal considers basic and applied research that explores all aspects of the degradation of metallic and non-metallic materials. The journal broadly defines ‘materials degradation’ as a reduction in the ability of a material to perform its task in-service as a result of environmental exposure.

Related Collections

With Collections, you can get published faster and increase your visibility.

Decoding Degradation: Advances in the Materials Genome

Publishing Model: Open Access

Deadline: Mar 20, 2026

Environmentally Assisted Fracture

Publishing Model: Open Access

Deadline: Mar 13, 2026

Please sign in or register for FREE

If you are a registered user on Research Communities by Springer Nature, please sign in