Dynamic Network‑ and Microcellular Architecture‑Driven Biomass Elastomer toward Sustainable and Versatile Soft Electronics

Published in Electrical & Electronic Engineering and Materials

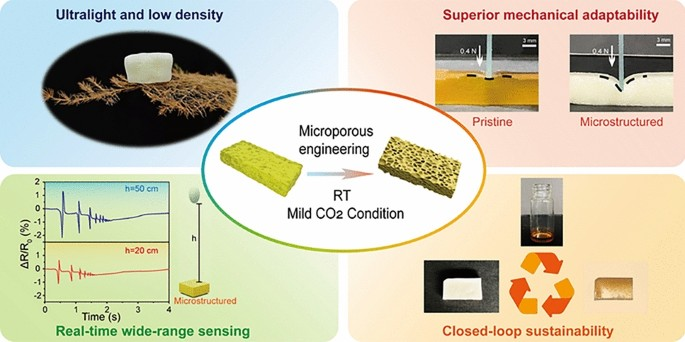

Soft sensors that feel gentle taps yet survive 500 % stretch still rely on petro-based rubbers and energy-intense foaming. A ZJUT–USTC–Xi’an Jiaotong team led by Prof. Shanqiu Liu and Prof. Jingguo Li now twists lipoic-acid chemistry into an ultralight (~0.25 g cm-3) biomass conductive elastomer that self-foams at room temperature under 2 MPa CO2, heals in 5 h and recycles five times without property loss. The resulting “micro-spring” lattice delivers a gauge factor of 4.8 under 1 % strain, rebounds 93 % after 200 % pull and tracks handwriting, heartbeat and ball drops in real time.

Why This Matters

- Mild, Scalable Foaming: CO2 plasticises dynamic disulfide/H-bond networks at 25 °C—80 % less energy and pressure than super-critical routes—yet yields 70 % porosity and 5× volume expansion.

- Micro-Spring Sensitivity: Closed cells act as strain amplifiers; GF jumps 3× in tension and 2.75× in compression versus the dense film, while cyclic drift stays <1 % over 100 cycles.

- Self-Healing & Closed-Loop Recycling: Cut samples rejoin at room temp, restoring 90 % mechanical and 98 % electrical performance; ethanol depolymerisation separates nano-fillers, ionic liquid and polymer for direct reuse.

- Green Feedstock: All building blocks (lipoic acid, SiO2, imidazolium sulfate) are bio-sourced or recyclable, cutting cradle-to-gate CO2 footprint by 45 %.

Innovative Design & Features

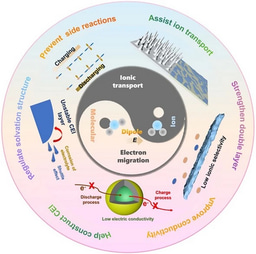

- Dynamic Crosslink Toolbox: Disulfide metathesis provides covalent reversibility; ionic liquid forms CO2-affinity sites that lower nucleation energy and furnish long-range ionic pathways (~0.65× dense-state conductivity).

- Tunable Architecture: Pore size (20–200 µm) and density are dialled by CO2 pressure (1–5 MPa) and nano-filler loading, giving density as low as 0.18 g cm-3—light enough to rest on a dandelion.

- Multi-Modal Sensing: Detects <1 % micro-strain, 50 µN contact force, 0.3 s rapid deformation and 5 °C temperature steps; handwriting and droplet impacts generate distinct, reproducible resistance patterns.

Applications & Future Outlook

- Wearable Health Patches: 300-µm film laminated on fabric monitors pulse, respiration and joint flexion with <0.05 s lag, surviving 10000 bend cycles.

- Soft-Robot Skin: Foam strips wrapped around grippers provide tactile feedback for delicate fruit handling, maintaining sensitivity after 500 % inflation.

- Circular Manufacturing: Team is scaling a roll-to-roll CO2chamber (1 m min-1) and exploring wireless BLE modules that dissolve in ethanol for tech-metal recovery.

By marrying a biomass backbone with CO2-blown micro-springs, the work offers a production-ready route to sensing foams that are light, tough, healable and endlessly reusable—pointing toward truly sustainable soft electronics that can be worn, folded, recycled and reborn.

Follow the Topic

-

Nano-Micro Letters

Nano-Micro Letters is a peer-reviewed, international, interdisciplinary and open-access journal that focus on science, experiments, engineering, technologies and applications of nano- or microscale structure and system in physics, chemistry, biology, material science, and pharmacy.

Please sign in or register for FREE

If you are a registered user on Research Communities by Springer Nature, please sign in