Engineering hydrophobic nanomaterials for high-speed impacts

Published in Electrical & Electronic Engineering

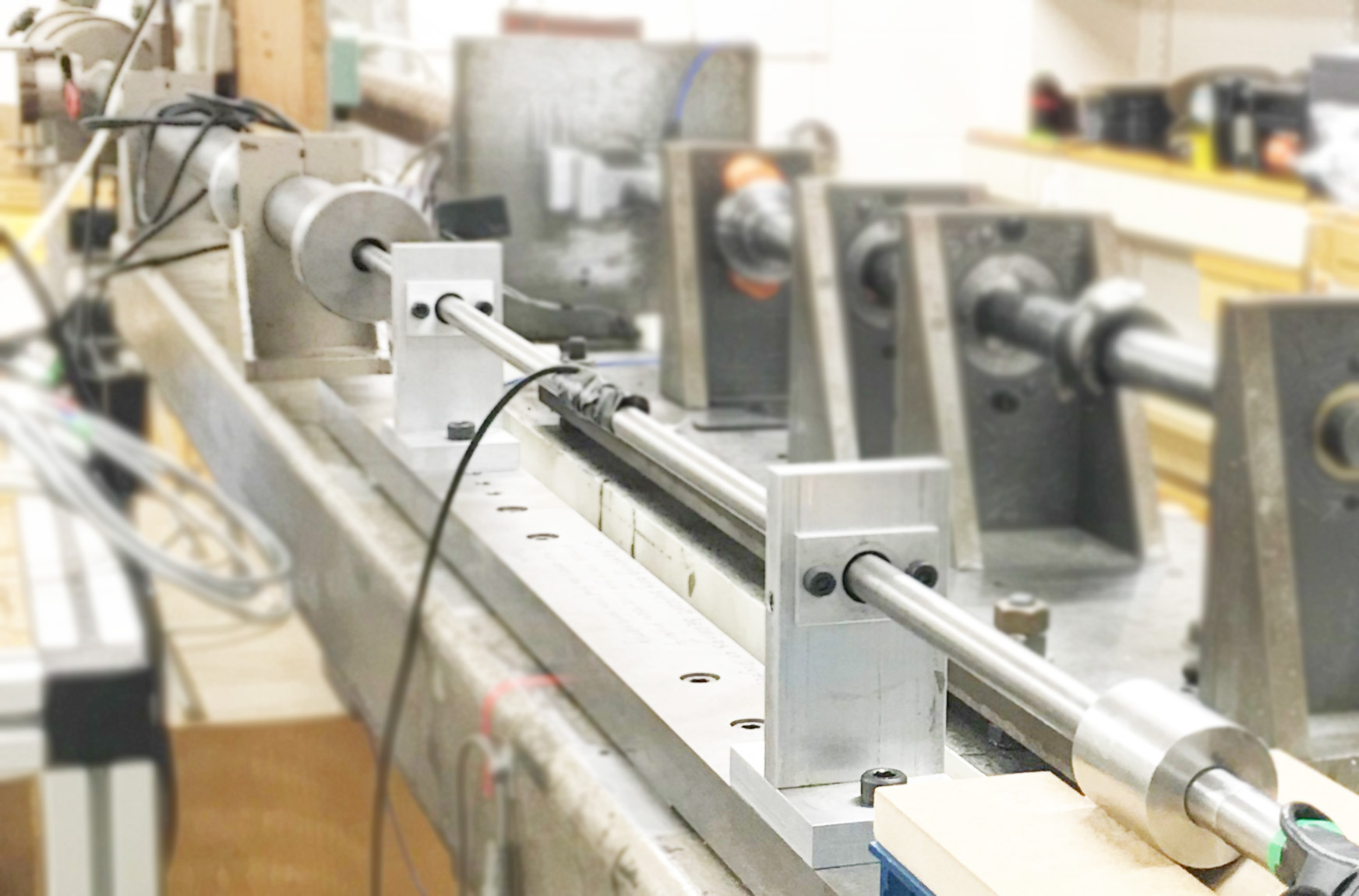

In 2017, Yueting (the University of Oxford, now a lecturer at the University of Birmingham) and I met at a conference in Greece. At that point, he and prof. Tan (Multifunctional Materials & Composites Laboratory) had started to investigate the forced intrusion of water in ZIF-8, the prototypical zeolitic imidazolate framework material. As ZIF-8 is a hydrophobic material, water does not spontaneously intrude inside its characteristic pore network. Instead, an external trigger—such as a mechanical impact—is needed to force water inside the ZIF-8 cages. When this external trigger is removed, water again extrudes from the material, although at a lower pressure than the intrusion pressure. Throughout this intrusion-extrusion cycle, the energy of the mechanical shock is partially converted. Under quasi-static conditions, this process is already well-documented in ZIFs and other hydrophobic materials such as zeolites.

What made our new experimental observations so exciting, however, is that the energy absorption capacity of ZIF-8 increases the higher the impact rate of the mechanical shock, up to 17-fold. In other words, the higher the speed at which the shock impacts the absorber, the more energy it can absorb. This is especially attractive as realistic shock absorption applications—both in an automotive and an industrial context—typically occur at impact rates much higher than those probed under quasistatic conditions. At that point, we met in Greece, and two main challenges arose:

- Can we fundamentally understand why the ZIF-8 absorption capacity increases upon higher impact rates?

- Can we use this same mechanism to design other shock absorption materials?

The intrusion mechanism unveiled

To understand the atomic origin of the intrusion mechanism, we applied a wide variety of computational techniques at the Center for Molecular Modeling (CMM, Ghent University) under the guidance of prof. Van Speybroeck. These enhanced sampling simulations demonstrated that water molecules experience a high free energy barrier to enter a hydrophobic ZIF-8 cage and to hop from one cage to a neighboring one. However, as shown in the video below, this barrier could be lowered by allowing a critical water cluster to form inside the pore. Once a critical cluster of about five water molecules is present, this cluster can interact with water molecules present in adjacent cages through hydrogen bonds. These attractive hydrogen bonds facilitate the hopping of additional water molecules to the cage containing the water clusters, effectively lowering the free energy barrier.

This atomic-level insight could also explain why forcing water inside the hydrophobic ZIF-8 cages leads to a much higher energy absorption capacity when the impact rate is higher than at quasi-static conditions. At quasi-static conditions, the above mechanism indicates that the first few water molecules in a cage need to overcome a high free energy barrier to intrude in the materials. However, afterward, these water molecules conglomerate in a critical cluster on an intrinsic nanosecond timescale and facilitate further water intrusion. As a result, subsequent water molecules need less energy to enter the cage, and the absorption capacity remains limited. In contrast, at high impact rates, the water molecules have insufficient time to conglomerate in clusters inside the cages and every water molecule experiences the same high barrier to intrude. As a result, the energy absorption capacity is enormously enhanced the higher the rate at which the mechanical shock impacts the material.

Designing new shock absorbers

Based on these experiments and simulations, we proposed four design criteria to design other shock absorption materials that should exhibit this attractive rate dependence.

- The material should be hydrophobic;

- The material should consist of discrete nanocages (in contrast to channels);

- The apertures connecting the nanocages should be sufficiently large to ensure reusability;

- Larger nanocages facilitate the formation of larger water clusters and hence increase the energy absorption density at high strain rates.

Based on these four design rules, we identified twenty materials that should exhibit this rate-dependent shock absorption behavior and would hence form attractive shock absorbers, some of which were also confirmed experimentally.

More information

These results were recently published in Nature Materials:

"High-rate nanofluidic energy absorption in porous zeolitic frameworks", Nat. Mater. DOI: 10.1038/s41563-021-00977-6.

Follow the Topic

-

Nature Materials

A monthly multi-disciplinary journal that brings together cutting-edge research across the entire spectrum of materials science and engineering, including applied and fundamental aspects of the synthesis/processing, structure/composition, properties and performance of materials.

Please sign in or register for FREE

If you are a registered user on Research Communities by Springer Nature, please sign in