Environmental sustainability, energy efficiency and uncertainty analysis of agricultural residue-based bioethanol production: A comprehensive life cycle assessment study

Published in Chemistry, Earth & Environment, and Ecology & Evolution

Explore the Research

elsevier.com

elsevier.com

ScienceDirect

About ScienceDirect Shopping cart Contact and supportTerms and conditionsPrivacy policy

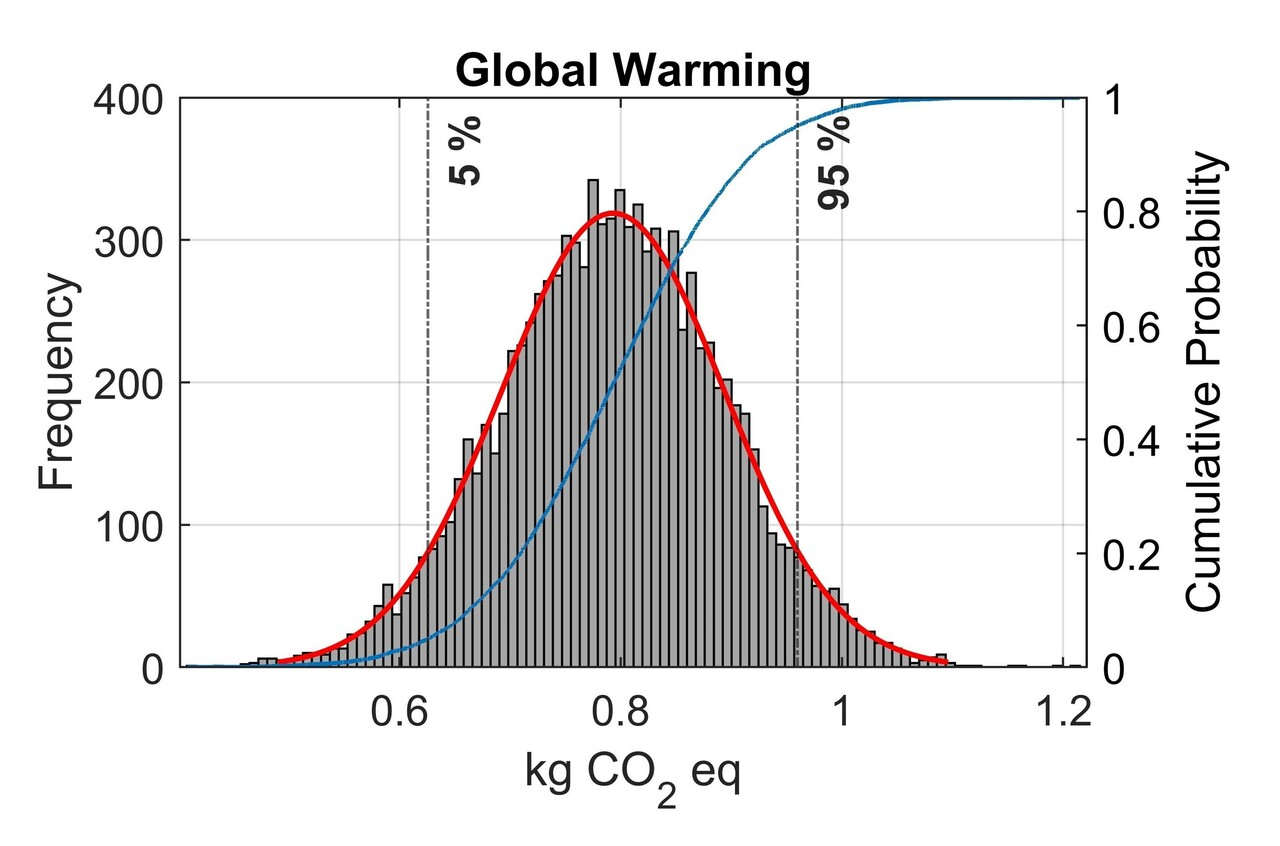

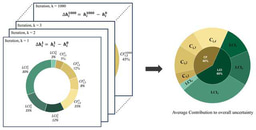

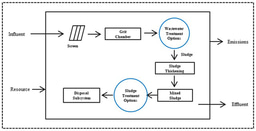

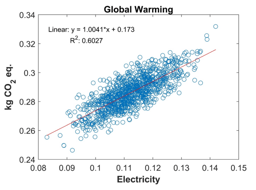

Bioethanol produced from agro-residue provides a sustainable alternative to fossil fuels, mitigating pollution, reducing waste, and promoting a circular economy. However, challenges arise in sustainable sourcing, resource conflicts, water quality concerns, and managing environmental footprints to maximize agro-residue-based bioethanol benefits. The environmental impacts, net energy ratio (NER), net energy value, water footprint, and uncertainties associated with bioethanol production from agro-residues are analyzed in this study. The analysis followed a cradle-to-gate approach using 1 L of bioethanol produced as a functional unit (FU), allowing for a direct comparison of the environmental performance of the different feedstocks. The result shows that rice strawbased bioethanol exhibited higher environmental impacts, particularly in terms of ecotoxicity, ionizing radiation, human toxicity, and ozone layer depletion, except for greenhouse gas emission, which is lowest for corn stover (0.37 kg CO2 eq. per FU) and highest for cassava straw (1.1 kg CO2 eq. per FU). Furthermore, the Cumulative Energy Demand analysis highlighted a significant reliance on fossil fuels from agricultural biomass throughout the bioethanol production process. The energy balance analysis shows that the agricultural residues are feasible for bioethanol production with NER of 1.20, 3.10, and 3.28 for rice straw, corn stover, and cassava straw, respectively. To enhance the accuracy and reliability of the LCA results, Monte Carlo simulation was employed to account for uncertainty and variability in the data. This methodology provides a better understanding of the impacts of bioethanol production, with a focus on sustainability and advancements in reducing our reliance on fossil fuels.

Please sign in or register for FREE

If you are a registered user on Research Communities by Springer Nature, please sign in