Sustainable biodiesel from used cooking oil: a comparative life cycle, energy, and uncertainty analysis

Published in Chemistry and Sustainability

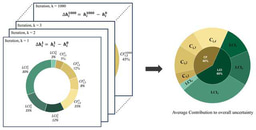

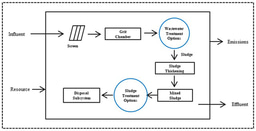

This study focuses on analyzing the environmental impacts of biodiesel production from Used Cooking Oil (UCO) as a waste management strategy. Using a cradle-to-gate life cycle assessment approach, it compares UCO-derived biodiesel with the first-generation biofuel derived from palm oil. The research addresses the pressing need for sustainable energy alternatives that reduce environmental impacts while promoting waste utilization. The study analyzes multiple environmental impact categories, cumulative energy demand (CED), and includes uncertainty analysis to address variability in data and assumptions across the life cycle. Regression and scatter plot analyses are used to identify correlations between inventory inputs and environmental effects. The study shows that the total carbon and environmental footprint per kg of biodiesel produced from UCO was 0.22 kg CO2 eq. and 0.11 mPt, compared to 9.87 kg CO2 eq. and 1.34 mPt for palm oil biodiesel. Electricity, methanol, and steam-derived heat are the primary factors influencing this emission. The total CED for UCO biodiesel was 6.78 MJ, compared to that of palm oil at 18.5 MJ. The net energy ratio of UCO biodiesel is 5.49, outperforming palm oil biodiesel (2.01) and conventional diesel (0.83). The study also shows significant reduction in impacts when including avoided products into the system boundary. The uncertainty of the study is within 10%, which confirms the reliability and robustness of the impact results for UCO biodiesel. This study provides valuable insights for decision-makers in the biofuel industry, promoting waste-to-energy solutions to reduce environmental footprints and support the transition to greener energy systems.

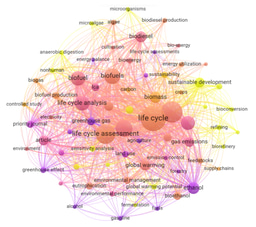

The research gap addressed by this paper lies in the need for a comprehensive and comparative analysis of biodiesel production from UCO, specifically in the context of sustainability, energy efficiency, and uncertainty. While significant research has been conducted on biodiesel production from conventional feedstocks like soybean, palm oil, and other edible oils, more detailed studies are needed to explore the potential of UCO as an alternative, non-food-based feedstock. Current literature often focuses on the environmental benefits of biofuels but may only partially account for part of the life cycle impacts, particularly in the case of biodiesel derived from waste materials. Furthermore, the energy efficiency of converting UCO into biodiesel, including the energy inputs required for collection, processing, and refining, still needs to be explored compared to traditional biodiesel sources. In addition, existing studies frequently need to pay more attention to the uncertainties associated with the availability, quality, and processing of UCO, leading to an incomplete understanding of the risks and variability in biodiesel production outcomes.

The analysis shows that for UCO biodiesel, electricity use has significant contribution in impact categories of ecotoxicity (40%), acidification (41%), global warming (43%), and eutrophication (47%), whereas methanol use in transesterification has significant contribution in carcinogens (78%) and non-carcinogens (35%), ozone layer depletion (52%), and respiratory organics (62%) impact categories. Using fertilizers during cultivation has high environmental impacts on Palm Oil biodiesel, followed by electricity and methanol.

Follow the Topic

-

Environment, Development and Sustainability

This is an international and multidisciplinary journal covering all aspects of the environmental impacts of socio-economic development.

What are SDG Topics?

An introduction to Sustainable Development Goals (SDGs) Topics and their role in highlighting sustainable development research.

Continue reading announcement

Please sign in or register for FREE

If you are a registered user on Research Communities by Springer Nature, please sign in