Exploring the colloid-to-polymer transition for ultra-low crosslinked microgels from three to two dimensions

Published in Chemistry

Soft materials are ubiquitous in every-day life, from the tissues composing our body to food, from day-care products to rubber in tires. The macroscopic properties of these materials, as their capacity to flow or their capability to crystallize or form glasses, are determined by the nature of their building blocks. In the last decades microgels, polymeric crosslinked networks with sizes between micrometers and tens of nanometers swollen in a good solvent, have attracted many attentions as building blocks for smart-soft materials. The interest for microgels relies on two fundamental aspects: (i) their polymeric nature emerges in their responsivness to external stimuli allowing to design soft-materials responsive to changes in their environments (temperature, pH); (ii) their colloidal nature leads to self-organizzation that determines the phase behavior and flow properties of the soft materials.

To date, microgels have always been considered as soft colloids, i.e. particles that maintain their individuality and show phase transitions between disordered and crystalline arrangements in both two and three dimensions. We answered the questions whether is it possible to have microgels with dominant flexible polymer nature. We have used the so called ultra-low crosslinked (ULC) microgels, obtained by precipitation polymerization. Although no crosslinking agents are present during the synthesis, the formation of a polymeric network is promoted via transfer reactions, leading to extremely soft microgels.

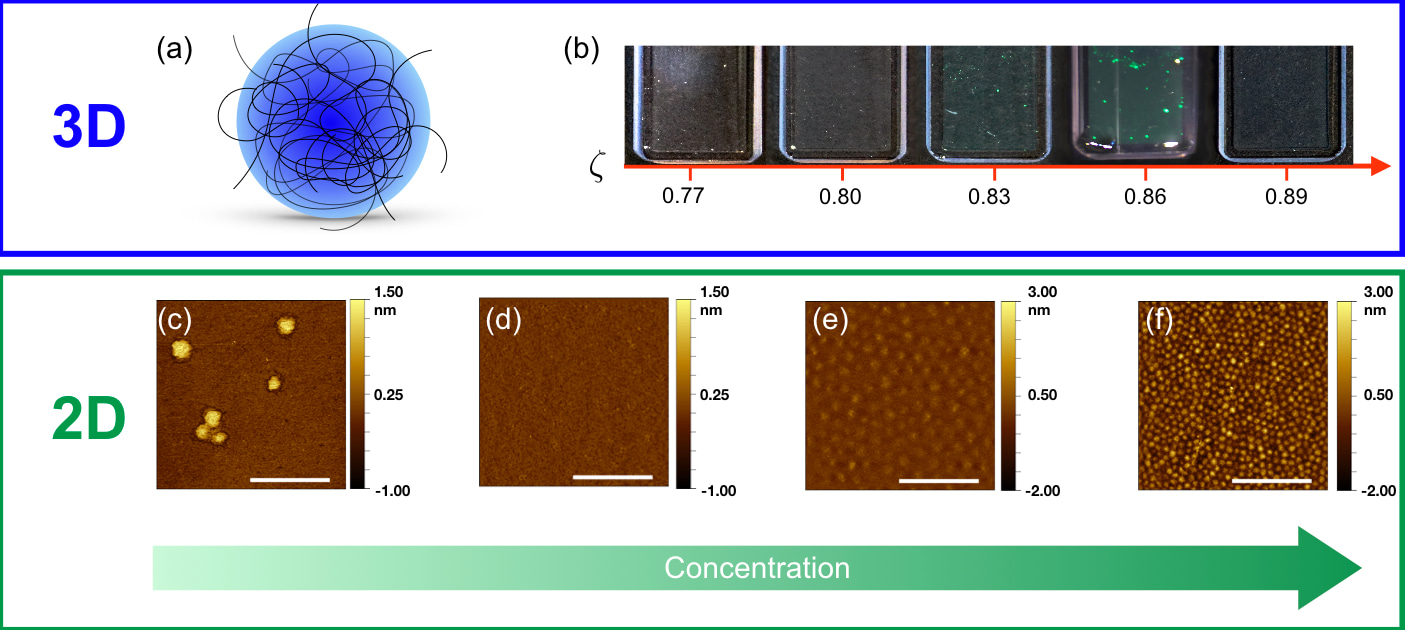

Small-angle neutron scattering reveals that ULC mcirogels possesses a more homogeneous structure with a less extended fuzzy shell with respect to regularly crosslinked microgels [Fig. 1(a)]. The extreme softness shifts the boundary of the transition between liquid and crystalline phase to higher concentrations in bulk [Fig. 1(b)]. Furthermore, bulk suspensions of ULC microgels have lower values for the yielding stress, as revealed by rheology measurements.

Fig. 1 (a) Sketch of a swollen ULC microgels in bulk. (b) Series of samples at different concentrations, generalized volume fration $\zeta$, showing liquid, crystal and glassy pahses. (c) - (f) AFM micrographs of ULC microgels at different concentrations, deposited on a solid substrate.

In constrast to the three-dimensions, for ULC microgels confined in two-dimensions, e.g. at the water-oil interfaces, the extreem softness has huge effects on their phase behavior making them substantially different than regularly crosslinked microgels. The analysis of the compression isotherms of a monolayer of ULC microgels and the atomic force microscopy (AFM) micrographs of the deposited micorgels in dry state on a solid substrate reveal that the flexible polymer nature dominates for low concentrations while the colloidal nature is restored once compression increases. Two important facts are shown in Figs. 1(c)-(f): (i) a transition of ULC microgels from a homogeneous coverage to disordered microgel-like layer that is fully reversible; (ii) a heterogeneous stretching of their loosely crosslinked polymeric with a consequent increase in the size polydispersity that either suppresses or significatively slow down the crystallization kinetic.

The capability of ULC microgels to behave either like flexible or like colloids depending on dimensionality and compression makes them the perfect model system to explore common properties and differences between them and regular microgels and other polymer architectures as star, hyperbranched and linear macromolecules.

If you want to read more about our work, check out this link:

Follow the Topic

-

Nature Communications

An open access, multidisciplinary journal dedicated to publishing high-quality research in all areas of the biological, health, physical, chemical and Earth sciences.

Related Collections

With Collections, you can get published faster and increase your visibility.

Women's Health

Publishing Model: Hybrid

Deadline: Ongoing

Advances in neurodegenerative diseases

Publishing Model: Hybrid

Deadline: Mar 24, 2026

Please sign in or register for FREE

If you are a registered user on Research Communities by Springer Nature, please sign in