High‑Entropy Materials: A New Paradigm in the Design of Advanced Batteries

Published in Chemistry, Materials, and Computational Sciences

As global energy demands surge and fossil-fuel reserves shrink, next-generation batteries must deliver higher energy density, longer cycle life, and extreme-temperature tolerance. Now, researchers from Fuzhou University—led by Prof. Minmin Zhu, Prof. Haizhong Zhang, and Prof. Xinghui Wang—have published a comprehensive review in Nano-Micro Letters showing how high-entropy materials (HEMs) meet these challenges across lithium, sodium, zinc, potassium, and wide-temperature systems. Their work provides a roadmap for entropy-driven battery design from alloy to oxide to MXene.

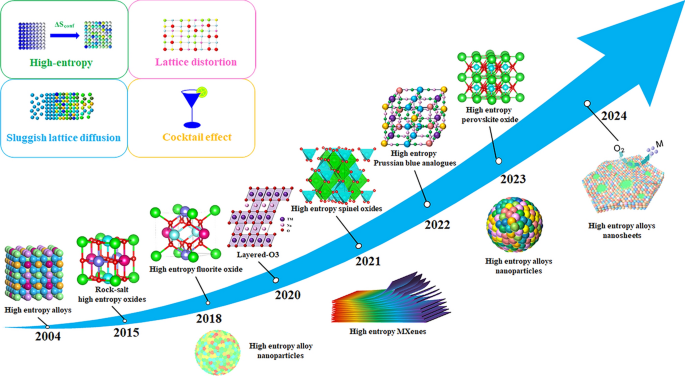

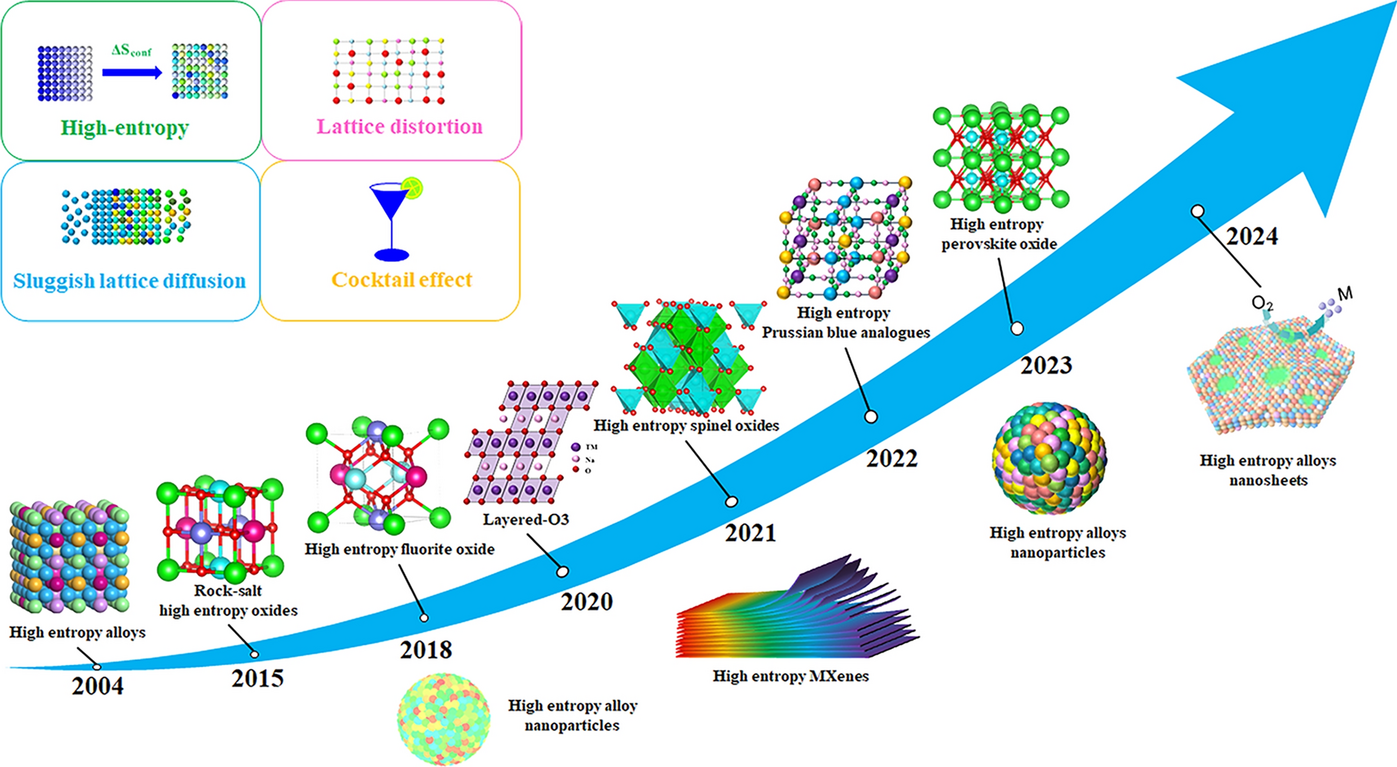

Why High-Entropy Materials Matter

- Structural Stability: High configurational entropy suppresses phase separation, lattice distortion, and transition-metal dissolution, extending cycle life to >5 000 cycles.

- Multi-Element Synergy: The “cocktail effect” tunes redox potential, ionic conductivity, and catalytic activity without costly noble metals.

- Wide-Temperature Resilience: Entropy stabilization maintains >90 % capacity from –50 °C to 80 °C, enabling aerospace and polar applications.

Innovative Design and Features

- Three Main Families: Review covers high-entropy alloys (HEAs), high-entropy oxides (HEOs), and high-entropy MXenes, each offering distinct electron/ion pathways.

- Composition Space: Equimolar or near-equimolar mixing of ≥5 principal elements maximizes configurational entropy (ΔSconf ≥ 1.5 R) to form single-phase solid solutions.

- Synthesis Toolbox: Carbothermal shock, liquid-metal reduction, sol–gel, and additive manufacturing produce nanoparticles, nanosheets, hollow fibers, and 3D-printed electrodes at ≤400 °C.

Applications and Future Outlook

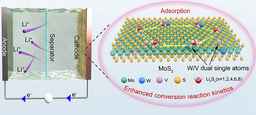

- Next-Gen Anodes: Co-free HEO spinel delivers 1 645 mAh g−1 at 0.2 A g−1 and 596 mAh g−1 after 1 200 cycles in Li-ion batteries.

- Sulfur Cathodes: HEA@N-doped carbon suppresses polysulfide shuttle, achieving 1 381 mAh g−1 initial capacity and 435 mAh g−1 after 400 cycles in Li–S cells.

- Solid Electrolytes: Garnet-type HEO raises Li+ conductivity to 0.62 mS cm−1 at –60 °C, enabling all-solid-state cells with 91 % retention after 100 cycles.

- Machine-Learning Acceleration: Active-learning models predict phase stability and catalytic activity, shrinking discovery time from years to weeks.

The review concludes by outlining scalable low-temperature synthesis, in situ characterization, and open-data platforms needed to translate HEMs from lab to gigafactory. Stay tuned for more breakthroughs from Prof. Zhu, Prof. Zhang, and Prof. Wang at Fuzhou University!

Follow the Topic

-

Nano-Micro Letters

Nano-Micro Letters is a peer-reviewed, international, interdisciplinary and open-access journal that focus on science, experiments, engineering, technologies and applications of nano- or microscale structure and system in physics, chemistry, biology, material science, and pharmacy.

Please sign in or register for FREE

If you are a registered user on Research Communities by Springer Nature, please sign in