The paper in Nature Communications is here: http://go.nature.com/2EH3X92

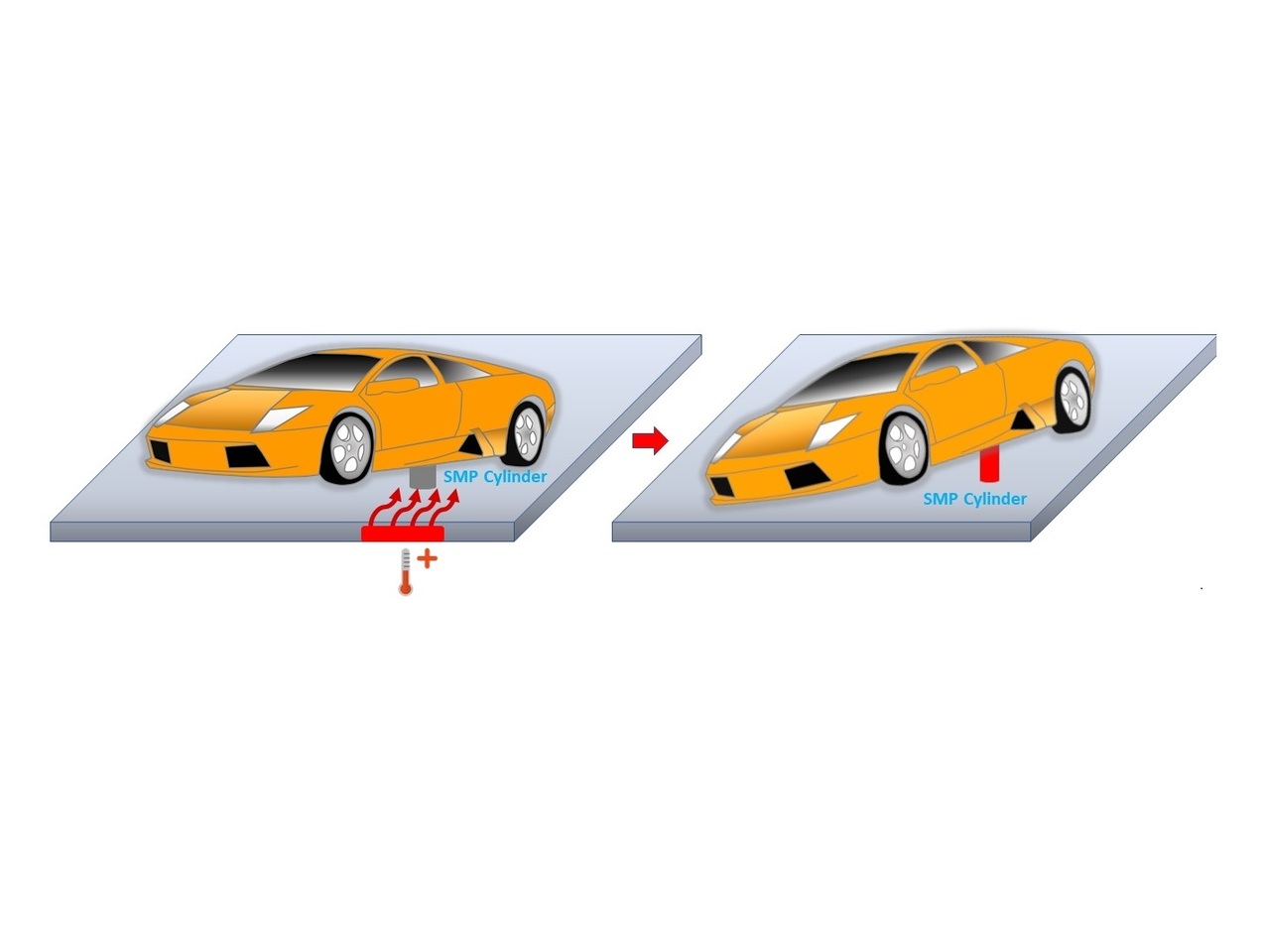

Can you imagine that a cylindrical polymer rod with a diameter of 4.6 cm and programmed height of 11 cm can jack up a car by simple heating? This can be done by our new shape memory polymers (SMPs) which is designed by a new energy storage mechanism.

Thermoset shape memory polymers have been a topic of intensive research for years. In addition to shape memory, which means a deformed temporary shape can restore its original permanent shape upon stimulation, such as heat, light, moisture, pH, etc., SMPs can also release stress if free shape recovery is not allowed. The fact that SMPs can memorize both shape and stress has rendered them with many potential applications such as actuators, self-healing, sealants, morphing structures, stent, suture, soft robot, smart textile, etc.

However, low output in stress and energy in the rubbery state has been a bottleneck for wide-spread applications of thermoset SMPs. In the literatures, the stable recovery stress is from tenths to several MPa and the energy output is several tenths MJ/m3. This suggests that the energy released by a 1cm3 sample can only lift 2 bottles of water (500g/bottle) by 1cm, a capability similar to a baby.

We believe that if more energy can be stored during the deformation process, or programming, more energy output can be achieved. Currently, entropy reduction is the acknowledged mechanism for energy storage in thermoset polymers. In addition to entropy reduction, we believe that enthalpy increase due to chemical bond length change is an option. Conventional polymer networks cannot store energy through enthalpy increase because the coiled segments in the rubbery state can endure giant deformation or ordering or entropy reduction without stretching the chemical bonds, or if the bond is stretched, it causes fracture. Hence, enriching the steric hindrance of the polymer network is a solution. Following this idea, a commercially available epoxy (EPON 826) is reacted with a rigid diamine named isophorone diamine (IPD), which can provide a large steric hindrance. A stable recovery stress of 17 MPa and energy output of 2.12 MJ/m3 in rubbery state and in bulk form are obtained and largely maintained.

If one wants to jack up one side of a car of 2,000kg by 2cm to change tire, 1,000kg force and 196J energy are needed. Based on our test result, which defines both programming strain and recovery strain per the original length, for a 45% compression programmed SMP sample, it can push 6MPa pressure by 10% strain. To push 1,000kg weight up by 2cm, a cylindrical SMP of 20cm tall and 4.6cm in diameter is sufficient. With 45% compression programming, the height becomes 11cm, which grows by 2 cm at 35% remaining strain. The recovery force is 9,966N, higher than the 9,800N force needed. Therefore, this cylinder can jack up the car by 2cm. The volume of the original cylinder is 332.2cm3, which can release 704J of energy. Hence, the energy conversion efficiency is 196J/704J = 27.8%. 100% conversion efficiency is possible if the weight is adjusted by following the recovery stress-strain curve.

Please sign in or register for FREE

If you are a registered user on Research Communities by Springer Nature, please sign in