Porous Microreactor Chip for Photocatalytic Seawater Splitting over 300 Hours at Atmospheric Pressure

As green hydrogen production gains urgency, photocatalytic seawater splitting offers a sustainable path—but catalyst stability in saline conditions remains a bottleneck. Now, researchers from Xiamen University, USTC, and SINANO-CAS, led by Prof. Fengzai Lv and Prof. Zhenchao Dong, present a porous Ag3PO4/CdS microreactor chip that maintains 0.81 % solar-to-hydrogen efficiency for >300 h in natural seawater under ambient pressure and visible light, marking a 30× leap in durability over prior systems.

Why This Chip Matters

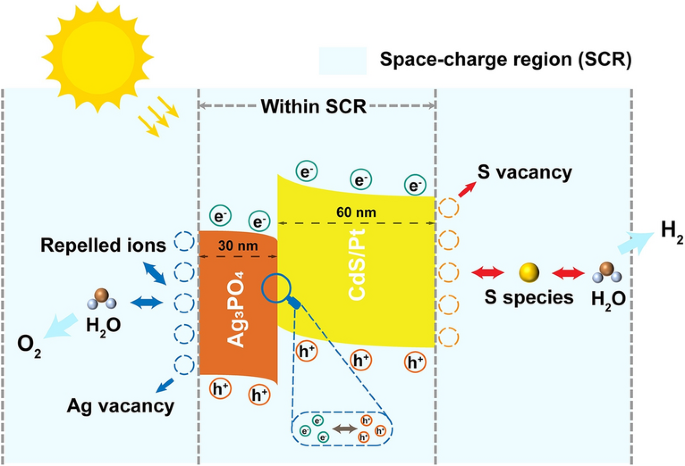

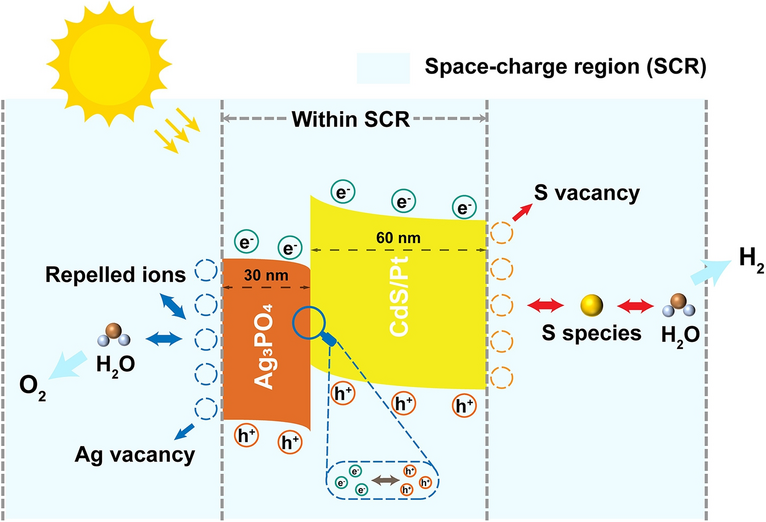

- Catalytic Selectivity: Ag vacancies repel Cl- ions; S vacancies anchor S-species and H2O, suppressing side reactions.

- Space-Charge Engineering: 30 nm Ag3PO4/60 nm CdS heterojunction stays within the 354 nm space-charge region, enabling band-bending-tuned carrier transport without loss of redox strength.

- Gas Separation: Layered geometry physically separates H2 and O2 evolution sites, cutting recombination.

- Scalability: A 256 cm2 outdoor prototype delivers 68 mmol H2 h-1 m-2 under natural sunlight—no vacuum, no cooling, no forced convection.

Innovative Design & Features

- Materials: Film-type Ag3PO4(O2 site) and CdS (H2 site) co-deposited on porous Al2O3; 0.3 nm Pt atomic clusters decorate CdS.

- Vacancy Control: O2 partial pressure during e-beam evaporation tunes Ag and S vacancy densities (EPR g = 2.003).

- Structure: 1–10 µm surface pores enhance mass transfer; cross-sectional EDS confirms sharp, continuous heterointerface.

- Characterization: KPFM visualizes 1.4 V contact-potential drop across the junction; thickness-dependent band bending verified by UPS, XPS, and EIS.

Performance & Outlook

- Stability: 25-day cyclic test (300 h total) shows <16 % activity loss; no delamination after “double-85” test (85 °C/85 %RH).

- Efficiency: 0.92 % peak STH (0.81 % average) in seawater; AQY 12.3 % at 420 nm; 18O-labeling confirms O2 from water oxidation.

- Scalability: Modular 1 m2 panel projected to yield 0.54 mol H2 day-1; circular reactor designed for varied terrain.

Challenges & Next Steps

Vacancy oxidation remains the dominant decay pathway; the team is now exploring in-situ vacancy regeneration and anti-fouling coatings to push lifetime beyond 1000 h.

This work provides a materials-by-design roadmap for saline-water splitting and demonstrates a ready-to-scale prototype that turns sunlight and seawater into fuel—no precious freshwater required.

Follow the Topic

-

Nano-Micro Letters

Nano-Micro Letters is a peer-reviewed, international, interdisciplinary and open-access journal that focus on science, experiments, engineering, technologies and applications of nano- or microscale structure and system in physics, chemistry, biology, material science, and pharmacy.

Please sign in or register for FREE

If you are a registered user on Research Communities by Springer Nature, please sign in