Predicting Plastron Thermodynamic Stability for Underwater Superhydrophobicity

Published in Materials, Microbiology, and Physics

Imagine a world where you dive underwater and remain dry. Imagine being able to glide effortlessly through the water with no frictional resistance. Staying dry underwater is essential for safety, health, functionality, operational efficiency, material integrity, and environmental protection. The following examples demonstrate the benefits of non-wettable coatings.

- Water wave energy is a promising green energy source that is independent of daylight, being second to fossil fuels.

- Scientific instruments and sensors utilized in underwater applications require protection from water ingress to maintain accuracy and reliability.

- Water conducts heat away from the body much faster than air. Staying dry helps retain body heat, preventing hypothermia, which is critical for divers and underwater workers.

- Keeping electrical components dry is critical to prevent short circuits, corrosion, and electrical failures enhancing their long-term durability in harsh underwater conditions, improving operational efficiency and cost-effectiveness.

- Dry underwater environments used in habitats and research stations are a fantastic way of minimizing disruption to marine life and ecosystems, which, in turn, facilitates more sustainable interactions with the underwater environment.

Non-wettable, superhydrophobic surfaces can trap a thin air layer, termed plastron, in rough protrusions providing surface resilience to the detrimental effects of wetting. However, developing such surfaces with long-lasting entrapped air is hampered by the lack of evaluation criteria, availability to create Young's surfaces, and experimental methods. This research describes a methodology for evaluating the thermodynamic stability underwater of superhydrophobic surfaces with the Cassie-Baxter wetting regime by measuring key surface parameters. The technique allowed the prediction of passive plastron stability for over a year of continuous submersion in water, the impeding of mussel and barnacle adhesion, and the inhibition of metal corrosion in seawater.

In general, each superhydrophobic surface can be characterized by measuring two specific apparent contact angles (CAs), which are the macroscopically measurable angles between the droplet and the solid at the three-phase contact line. The apparent CAs can be measured by fitting a model such as Laplace-Young to the droplet edge and the baseline, which is the line connecting the two three-phase contact points in the side-view image of a droplet. These two specific apparent angles are the advancing and receding CAs, which are the largest and smallest metastable apparent CAs on a given surface. Many studies use an average of static CA and CAH values to report the quality of artificially made superhydrophobic surfaces. However, a static CA, which is measured from a droplet after it has landed on the surface, does not contain relevant information about the wetting regime. Furthermore, there are several difficulties with these measurements. First, it is challenging to measure these values for surfaces with remarkably high CA (e.g., >170○) and incredibly low CAH (e.g., <1○). The latter is difficult due to the tendency of drops to roll off rapidly from these surfaces, and the former is due to the unreliability of the measured CAs resulting from minor changes in the baseline location.

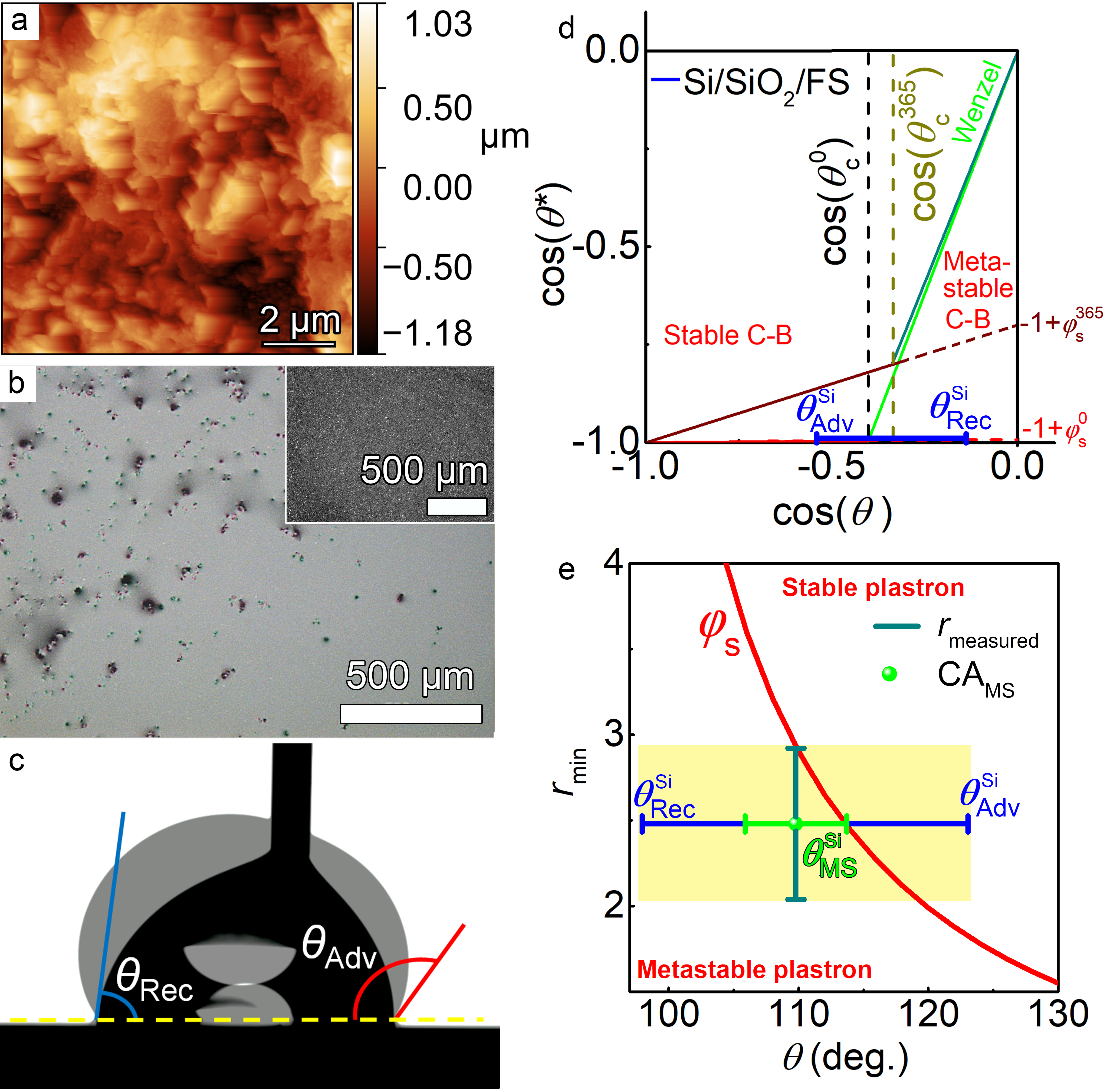

Besides, goniometric measurements do not explicitly reveal the plastron characteristics of submerged solid surfaces. This is because multiple wetting regimes may exist on the same surface, that is Cassie-Baxter or Wenzel, some of which are stable, while others are metastable. More specifically, there is no standard method for characterizing the plastron of submerged superhydrophobic surfaces. To be useful in underwater applications, superhydrophobic surfaces should be in the stable Cassie-Baxter wetting regime that allows for a meaningful lifetime of the plastron. Here, we propose a method for characterizing superhydrophobic surfaces, particularly those in the Cassie-Baxter wetting regime for underwater applications. It is crucial to characterize plastrons on solid surfaces underwater in terms of surface roughness, solid-liquid area fraction, and Young's CA.

- The dimensionless surface roughness parameter (r) as defined by Wenzel is calculated by dividing the actual surface area by the projected area.

- The solid-to-liquid area fraction (φs) represents the portion of the projected surface area, where water is in contact with the solid substrate.

- Young’s CA value is estimated by the most stable CA.

By measuring these three parameters, we can apply the thermodynamic theories described by Lafuma and Quéré, and/or Marmur to determine the wetting regime of the developed SHS, either stable or metastable Cassie-Baxter wetting regime, which predicts the longevity of the plastron as shown in Fig. 1.

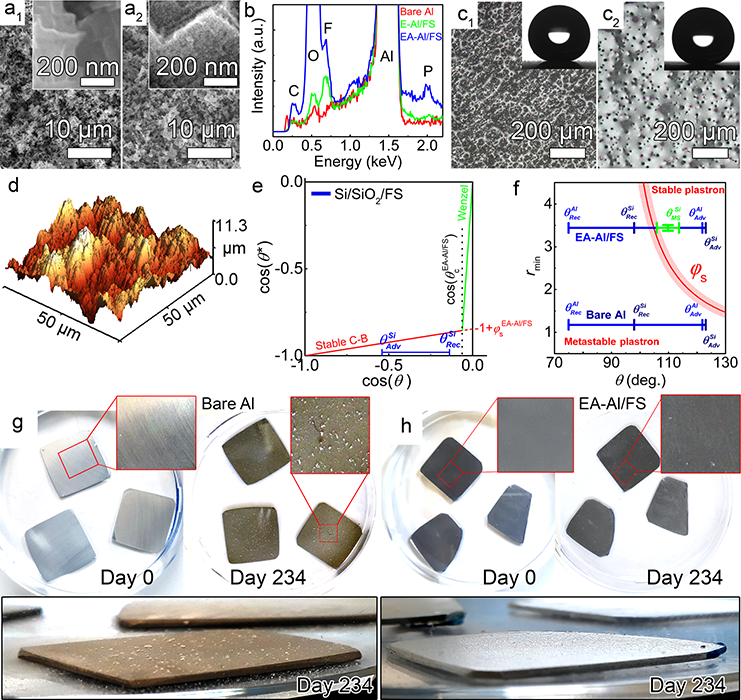

To prove the general applicability of the proposed characterization methodology, it was applied to superhydrophobic surfaces made from aluminum (Al). The micro-nanostructures were fabricated first by (i) chemical etching followed by (ii) electrochemical anodization. These samples were coated with fluorinated surfactant. The static CAs were measured and found to be comparable. Both types of superhydrophobic surfaces exhibit a Cassie-Baxter wetting regime with comparable advancing and receding CAs resulting in the landed drops rolling off instantly. The roughness parameter was measured by atomic force microscopy yielding a two-times higher value for etched/anodized Al samples. The plastron shape and coverage were estimated using digital still imaging and bright-field optical reflectance microscopy on the submerged samples. While both exhibit highly reflective surfaces underwater due to plastrons that cover the entire sample area, the bright-field optical reflectance microscopy images reveal a completely different plastron shape and solid-liquid area fraction. While the plastron on the etched/anodized Al samples was continuous with randomly distributed round pinning points, the etched Al samples demonstrated an irregular, broken shape. Using the theories above, the stability of plastrons underwater was estimated, predicting stable plastron for the etched/anodized Al samples only.

To evaluate our hypothesis of plastron stability, the corrosion resistance of the developed superhydrophobic Al surfaces was examined in artificial seawater. The etched superhydrophobic Al surfaces exhibit pronounced corrosion products already after one day of immersion due to the loss of plastron and exposing high surface area substrates to a corrosive medium. At the same time, the etched/anodized superhydrophobic Al surfaces exhibit corrosion-free performance even after ~8 months (247 days) of continuous immersion in seawater still demonstrating a highly reflective plastron (Fig. 2).

This research breaks through the "wall of plastron metastability" and proves that stable (passive) air entrapping underwater is feasible. The proposed methodology facilitates the quantification of plastrons, thus resulting in projections of the superhydrophobic coating's protective capability over months and even years of continuous immersion underwater. However, challenges remain in accurately predicting the stability of plastrons in a real-world environment, experimental methods, and surface preparation techniques.

Follow the Topic

-

Communications Materials

A selective open access journal from Nature Portfolio publishing high-quality research, reviews and commentary in all areas of materials science.

Related Collections

With Collections, you can get published faster and increase your visibility.

Advanced characterizations of high-entropy materials

Publishing Model: Open Access

Deadline: Mar 31, 2026

Multifunctional hydrogels

Publishing Model: Open Access

Deadline: Feb 28, 2026

Please sign in or register for FREE

If you are a registered user on Research Communities by Springer Nature, please sign in