Predicting the Yield of Solar Modules

Published in Physics

To understand how well a solar panel will work, we need to look at lots of different things. We have to consider how the semiconductor materials in the panel react to light, how the electricity flows through the panel, and what the real-world conditions will be like where the panel is installed.

We have created a computer program that can simulate all of these things for different types of solar panels. The program uses a few different models to predict how the panel will perform under different conditions. It can help us figure out how much energy the panel will produce over time, and how sensitive it is to changes in different parameters.

All we need to input into the program are some basic measurements and characteristics of the materials used in the panel. This can help us optimize the design and understand more about the panel's performance, even for parameters that are difficult to measure directly.

The consumption of fossil fuels causes carbon dioxide emissions and climate change. To meet demand while reducing emissions, we need to develop sustainable electricity generation technologies. Thin-film solar modules are promising candidates due to their high cell efficiencies, low energy and active material consumption in production, and their potential for cheap and large-scale manufacturing. They are also suitable for ink-based fabrication techniques, and can be used for photoelectrochemical hydrogen production and on flexible substrates.

To compete with the market-dominating silicon technology, thin-film technologies need to have high efficiencies, which can be analyzed through computer simulations. It is essential to investigate entire modules in the field, rather than only cells in the laboratory, to identify and quantify all loss mechanisms. A holistic simulation method that includes all loss mechanisms from the theoretical maximum efficiency limit (Shockley-Queisser model) to the actual produced module power is necessary.

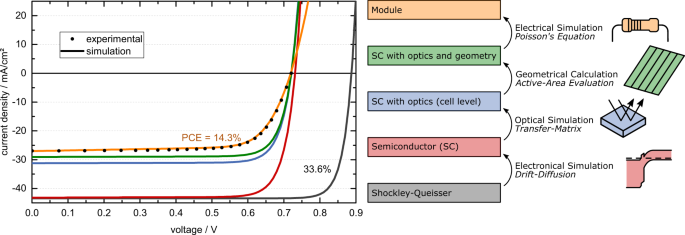

The authors of this study developed a unique simulation platform that links three simulation levels. It includes an electrical drift-diffusion model within a one-dimensional finite element method for semiconductor material simulation, a modified transfer-matrix approach to consider the optical behavior with partially incoherent interference due to rough interfaces, and an electrical Poisson's equation solver embedded into a quasi-three-dimensional finite element method to account for the electrical module behavior. The methodology includes the entire chain of physical processes within the simulation of solar modules, bridging the gap between cell simulation and system design software. The simulation allows the determination of characteristic parameters from experimental curves on the module level, which is called Reverse Engineering Fitting (REF). The approach also allows for sensitivity analysis of possible research improvements, a useful guide to set priorities in the research and development process.

The authors demonstrate the universal approach on a large copper indium gallium diselenide (CIGS) module N-G1000E105 from NICE Solar Energy GmbH. It consists of 144 monolithically integrated cells and the following layer stack: 400 nm molybdenum (Mo) / 2100 nm CIGS / 50 nm cadmium sulfide (CdS) / 50 nm intrinsic zinc oxide (i-ZnO) / 800 nm aluminum-doped zinc oxide (AZO) / 750 μm encapsulant film / 3.2 mm top side ARC-coated low-iron solar float glass.

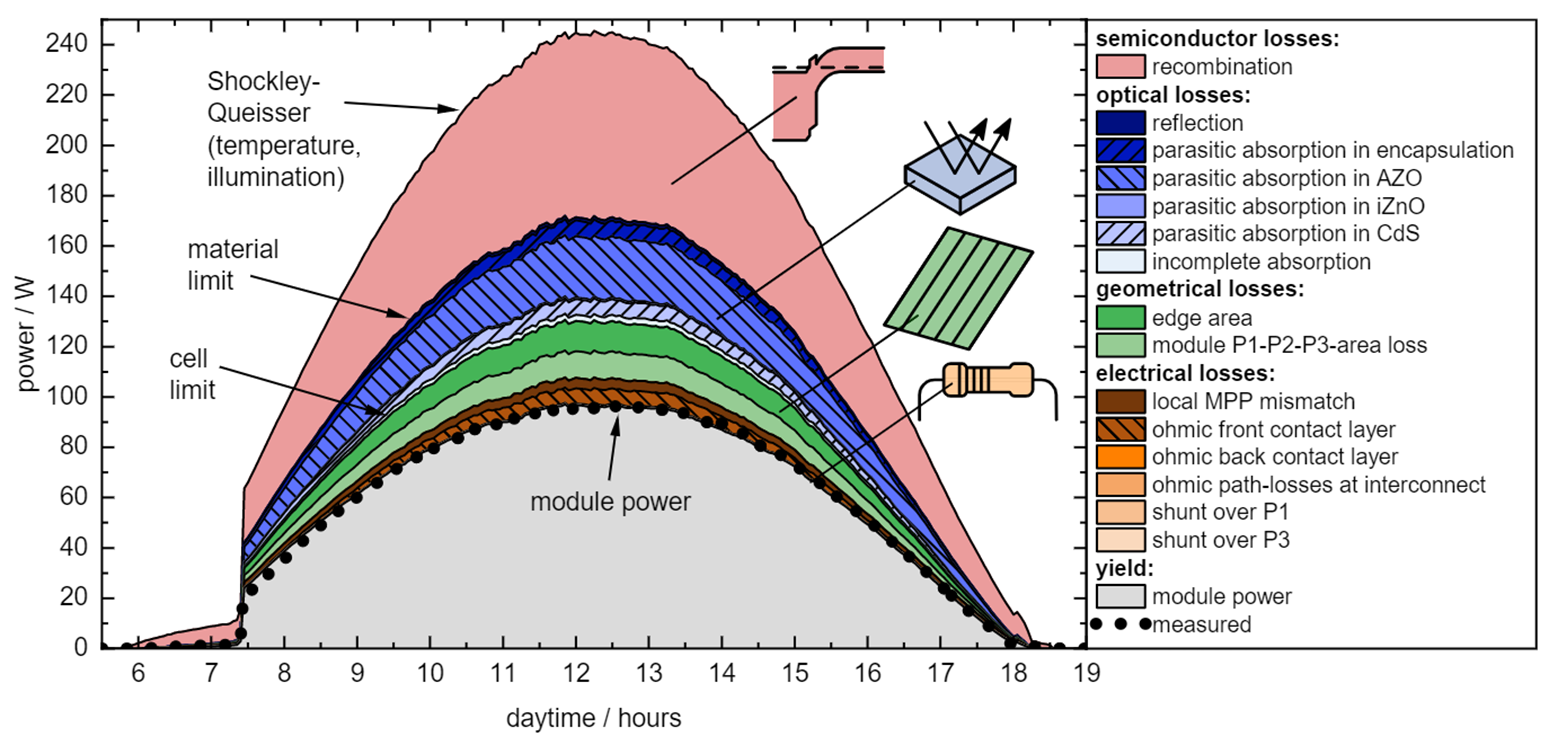

Figure 1 shows the electrical behavior of the mentioned solar module across the entire daytime of September 9, 2020 at the solar test field in Widderstall, Germany. The input information for such calculations besides the geometry of the module are the prevailing module temperatures and irradiation conditions as a function of time. The top of the red area is the theoretical maximum produced power, while all colored areas are loss mechanisms in the different simulations. The remaining gray area shows the effectively produced power on this day, while the black points represent the actually measured data. The high agreement demonstrates the precision of the given coupled multi-level simulation approach.

Figure 1: Loss analysis and generated module power during daytime of September 9, 2020. The material abbreviations CdS, i:ZnO, and AZO stand for cadmium sulfide, intrinsic zinc oxide, and aluminum-doped zinc oxide, respectively, MPP is the maximum power point, and P1, P2, and P3 describe the area required for module interconnection between individual cells. The upper edge of the red area represents the theoretical physical maximum efficiency limit for a band gap of 1.13 eV adapted for the module size and the prevailing illumination and temperature. After all losses are identified and quantified, the module is predicted to produce the power indicated within the gray area. Actual measurements in the field are marked as black dots.

This study demonstrates a holistic approach to simulate solar modules under real conditions, allowing for top-down loss analyses, determination of the influence of possible future technology improvements on yield, and backward calculations from measured data to determine difficult-to-measure parameters. The simulation model can predict solar-module parameters, even for conditions that are far beyond standard testing conditions, with remarkable accuracy. Such simulations can also be extended to yield predictions for an entire day based on meteorological data.

In conclusion, the presented study shows that thin-film solar modules are promising candidates for environmentally friendly electricity generation technologies. The presented simulation platform can investigate all loss mechanisms in thin-film solar modules, allowing for sensitivity analysis of possible research improvements and prioritization of the research and development process. The simulation can predict solar-module parameters under real conditions, helping investors determine financial returns. This work offers a significant step towards reducing emissions and combating climate change.

Follow the Topic

-

Communications Physics

An open access journal from Nature Portfolio publishing high-quality research, reviews and commentary in all areas of the physical sciences.

Related Collections

With Collections, you can get published faster and increase your visibility.

Higher-order interaction networks 2024

Publishing Model: Open Access

Deadline: Feb 28, 2026

Physics-Informed Machine Learning

Publishing Model: Hybrid

Deadline: May 31, 2026

Please sign in or register for FREE

If you are a registered user on Research Communities by Springer Nature, please sign in