Scalable Fabrication of Methylammonium‑Free Wide‑Bandgap Perovskite Solar Cells by Blade Coating in Ambient Air

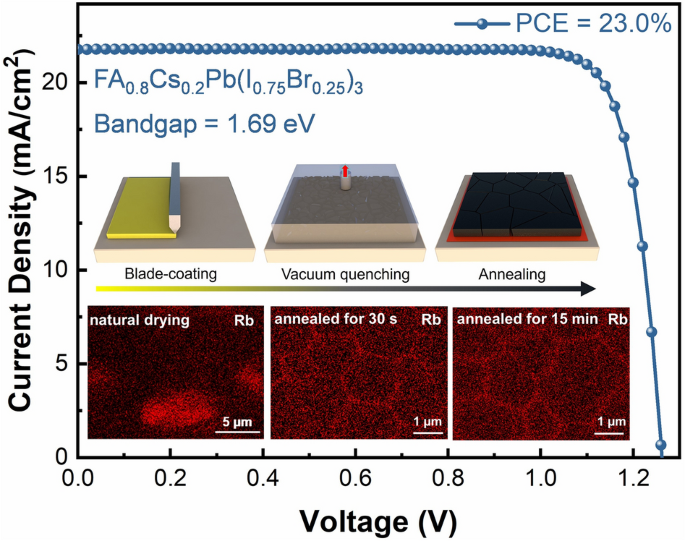

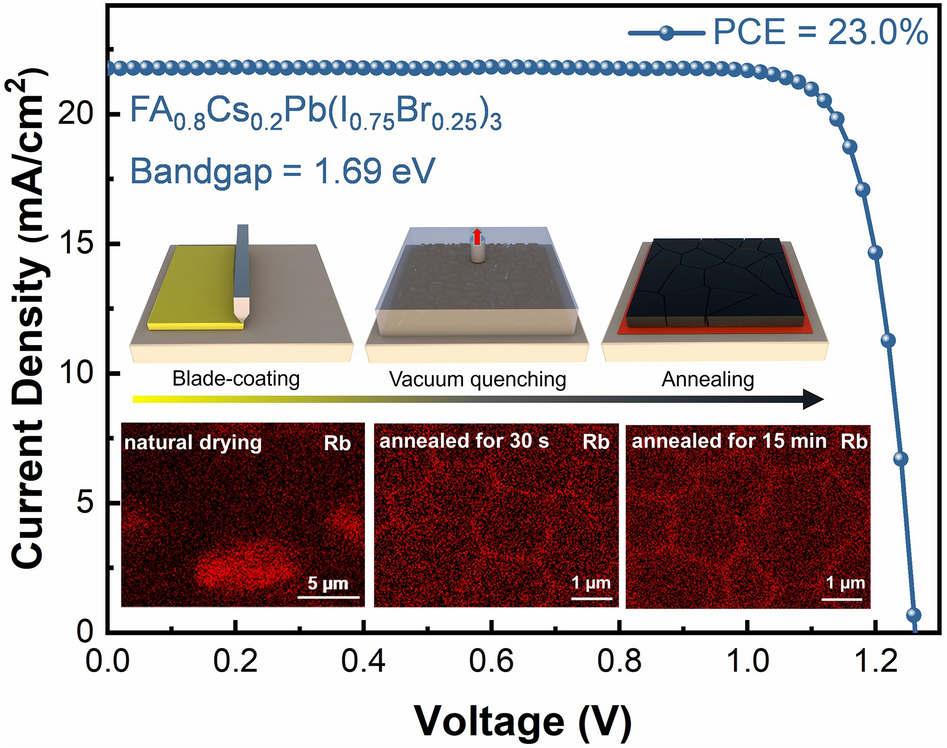

Wide-band-gap perovskites are the key top-cell for >30 % tandem modules, yet spin-coating and methylammonium (MA) instability block factory-scale production. Now researchers from Southwest Petroleum University, UNSW and UCL have formulated an MA-free ink that can be blade-coated in ambient air and delivers certified 23 % efficiency—one of the highest values ever reported for a 1.69 eV MA-free film.

Why This Matters

- Air-processable: 23 % small-area cell and 20.2 % 10.5 cm2 mini-module fabricated entirely in room air—no glove-box.

- MA-free stability: eliminates MA cation de-protonation and proton migration, extending operational lifetime (80 % PCE retained after 320 h MPP tracking at 45 °C).

- Factory friendly: blade-coating + vacuum-quench compatible with metre-wide roll-to-roll lines and existing tandem equipment.

Innovative Design & Features

- RbI + Pb(SCN)2 synergy: Rb ions segregate to grain boundaries, suppress PbI2 precipitation while preserving micron-scale grains; Pb(SCN)2 slows nucleation for compact, low-defect films.

- Intermediate-phase control: 2-imidazolidinone additive stabilises a metastable solvate that converts to pure α-phase perovskite during 120 °C anneal.

- Graded interface: PEAI/EDAI2 surface layer plus Al2O3 nano-sheet scaffold minimise non-radiative recombination and push V_OC to 1.26 V.

Applications & Future Outlook

- Tandem ready: band-gap (1.69 eV) and current density (21.75 mA cm-2) matched to c-Si bottom cells; modules retain 92 % PCE after 1,100 h ambient storage.

- Upscaling roadmap: uniform 5 × 5 cm2films verified by XRD mapping; laser-patterned mini-modules show negligible area loss (fill factor 76 %).

- Industry impact: simple, low-temperature process shortens the efficiency-cost-stability gap for perovskite/silicon tandems and accelerates gigawatt-scale manufacturing.

This work offers a clear, additive-guided pathway to print stable, high-performance wide-band-gap layers under factory air—bringing low-cost, high-efficiency tandem photovoltaics one step closer to market deployment.

Follow the Topic

-

Nano-Micro Letters

Nano-Micro Letters is a peer-reviewed, international, interdisciplinary and open-access journal that focus on science, experiments, engineering, technologies and applications of nano- or microscale structure and system in physics, chemistry, biology, material science, and pharmacy.

Please sign in or register for FREE

If you are a registered user on Research Communities by Springer Nature, please sign in