Motivation

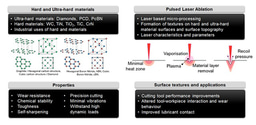

Repairing cutting tools using laser machining is one potential way to improve sustainable practices in the tool industry. Lasers are a precise and non-contact operation capable of micro-machining. Currently, laser machining of cutting tool materials particularly cemented carbides (WC-Co) improves the interaction between the cutting tool surface and workpiece material. However, there is little work in using laser machining to repair cutting tool damage.

For laser machining to be a possible repair option, the cutting tool material response needs to be thoroughly understood, non-optimized laser parameters will cause mechanical and thermal defects including porosity, balling, cracking, recast layer and heat-affected zone (HAZ).

The presence of these defects will limit tool performance and tool life and they act as stress raisers and points of crack initiation, as cutting tools are subjected to large loads and forces.

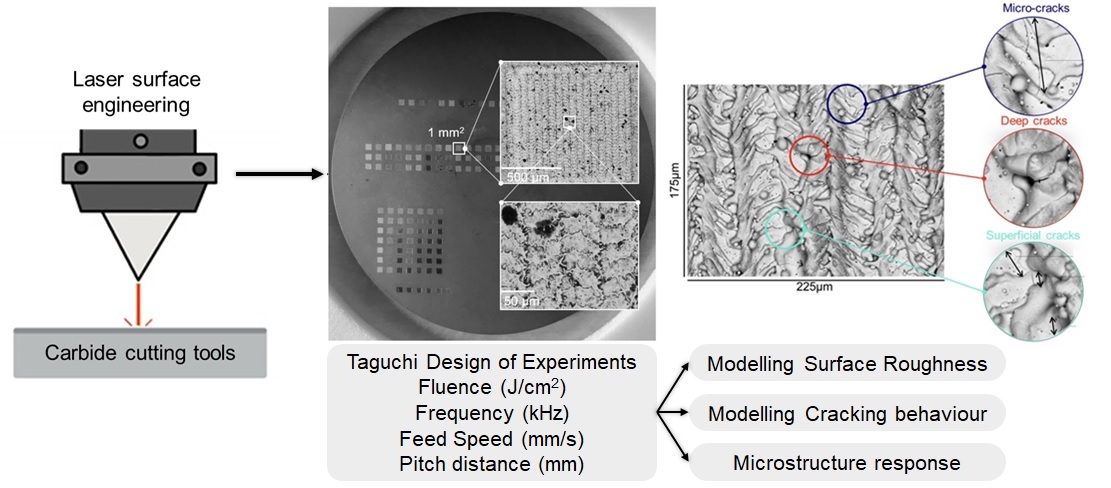

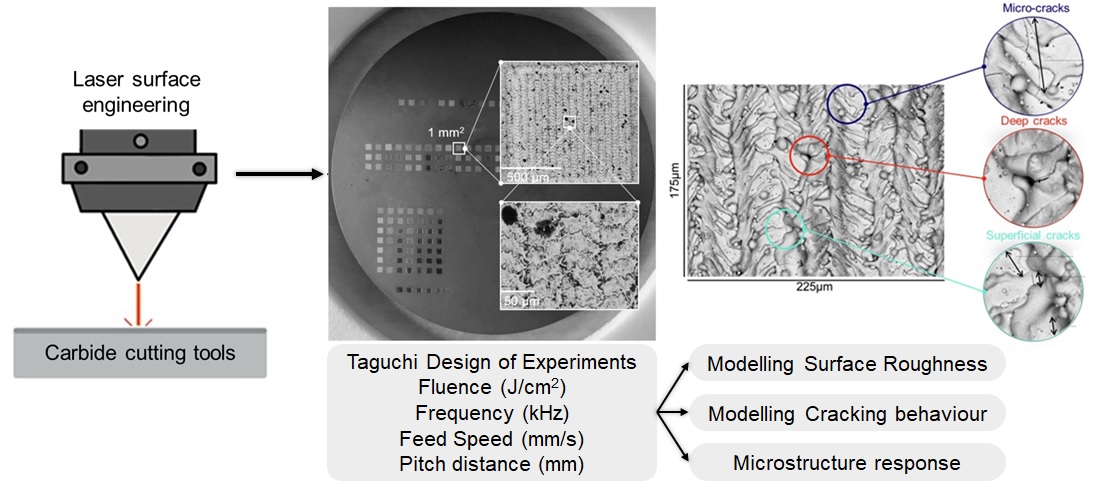

Therefore our study aimed to thoroughly understand the effects of laser parameters on cutting tools by modelling surface roughness and crack density then evaluating the surface integrity (Figure 1).

Figure 1. Overview of laser experimentation and crack classification.

Getting results

A 70W micro-machining fiber laser system with a 1060 nm wavelength and 240 nanosecond pulse duration was used.

Taguchi design of experiments (DOE) using 4 factors: fluence, frequency, feed speed, and pitch distance in addition linear orthogonal experiments were carried out. Statistical modelling via ANOVA analyzed the effects of the laser parameters.

White light interferometry (WLI) (Alicona Infinite Focus) was the simplest and easiest way to measure the 2D and 3D surface roughness. Scanning electron microscopy (SEM) (TM3030 Hitachi backscatter SEM) evaluated the surface integrity and viewed the microstructure after laser processing. Energy-dispersive spectroscopy (EDS) analysis for chemical composition was included with SEM.

We also developed a new method to estimate crack density and characterize crack formation:

- Cracks were classified into three categories based on size: superficial cracks, micro-cracks and deep cracks by SEM inspection of the samples.

- Superficial cracks were faint, hairline scratches (length up to 20 μm).

- Micro-cracks were thicker cracks or cracks longer than 20 μm (length up to 100 μm, width up to 3 μm).

- Deep cracks were cracks that caused significant damage/breakage or void-like failures (or length ≥ 20 μm and width > 3 μm).

- The length of cracks was measured by importing the SEM image into MATLAB and overlaying a straight line from one end to the other.

- The total number of cracks from each sample was then compared to the fluence and frequency settings used to process that sample, allowing for an ANOVA result to be computed.

Results Summary

The following are a few of the findings concluded from the study:

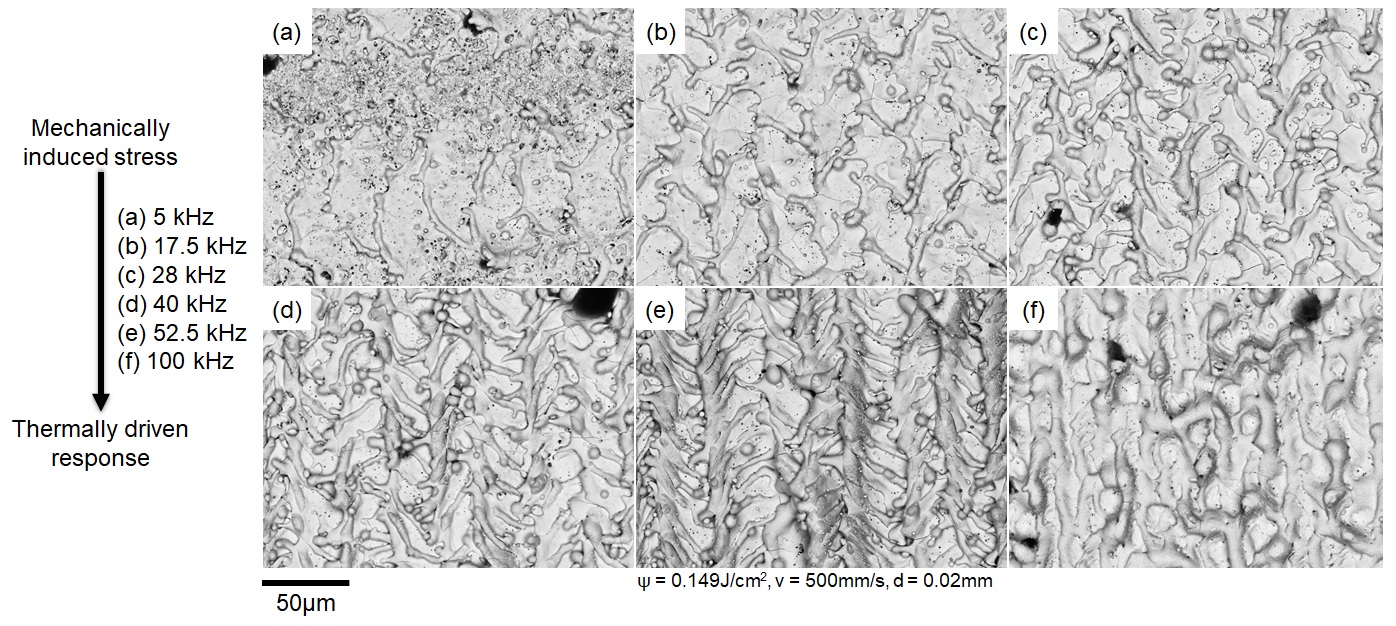

- The induced surface damage ranged from crack formation, porosity, balling, to spherical pores.

- The severity and presence of each were dependent on the laser parameters selected, demonstrating the need to understand the relationship between parameters and surface integrity (Figure 2).

- Generation of a numerical linear model to predict the surface roughness in relation to the distribution of surface peaks generated by laser processing, using DOE and ANOVA optimization techniques.

- Understood how to minimize surface defects allows for optimization of the laser parameters to produce an acceptable surface integrity.

- It was important to generate the crack density technique to have a quantitative analysis of crack formation as there is currently no universal way of quantifying cracks based on type.

- The findings of the present work are important as they provide a basic framework for understanding the material science interaction during the laser processing of WC to enable the next steps for laser machining as a repair method to begin to minimize and avoid inducing defects that hinder tool performance.

Figure 2. Progressive surface integrity transition as frequency changes.

If you are interested in our work, please refer to the review “Understanding the surface integrity of laser surface engineered tungsten carbide” published in The International Journal of Advanced Manufacturing Technology

DOI: 10.1007/s00170-021-07885-8

Hazzan KE, Pacella M, See TL. Understanding the surface integrity of laser surface engineered tungsten carbide. Int J Adv Manuf Technol 2022;118:1141–63. https://doi.org/10.1007/s00170-021-07885-8

Please sign in or register for FREE

If you are a registered user on Research Communities by Springer Nature, please sign in