Thinnest Freestanding Plastic Film Stretched

Published in Materials

1. The Challenge of Thinness

Plastic films are among the most used materials in modern life, from packaging to engineering applications. For decades, researchers have tried to reduce film thickness while maintaining mechanical strength, aiming to enhance efficiency and reduce material use. Reducing film thickness by 90%, for instance, could cut plastic consumption significantly without compromising performance. The question is: how thin can we go without sacrificing functionality?

Common methods struggle to achieve large-area thinness, with commercial polyethylene films rarely breaking the 1-micron threshold. Even the latest lab-made films, typically under 100 square centimeters, are difficult to produce freestanding and often lose mechanical integrity when stretched thinner.

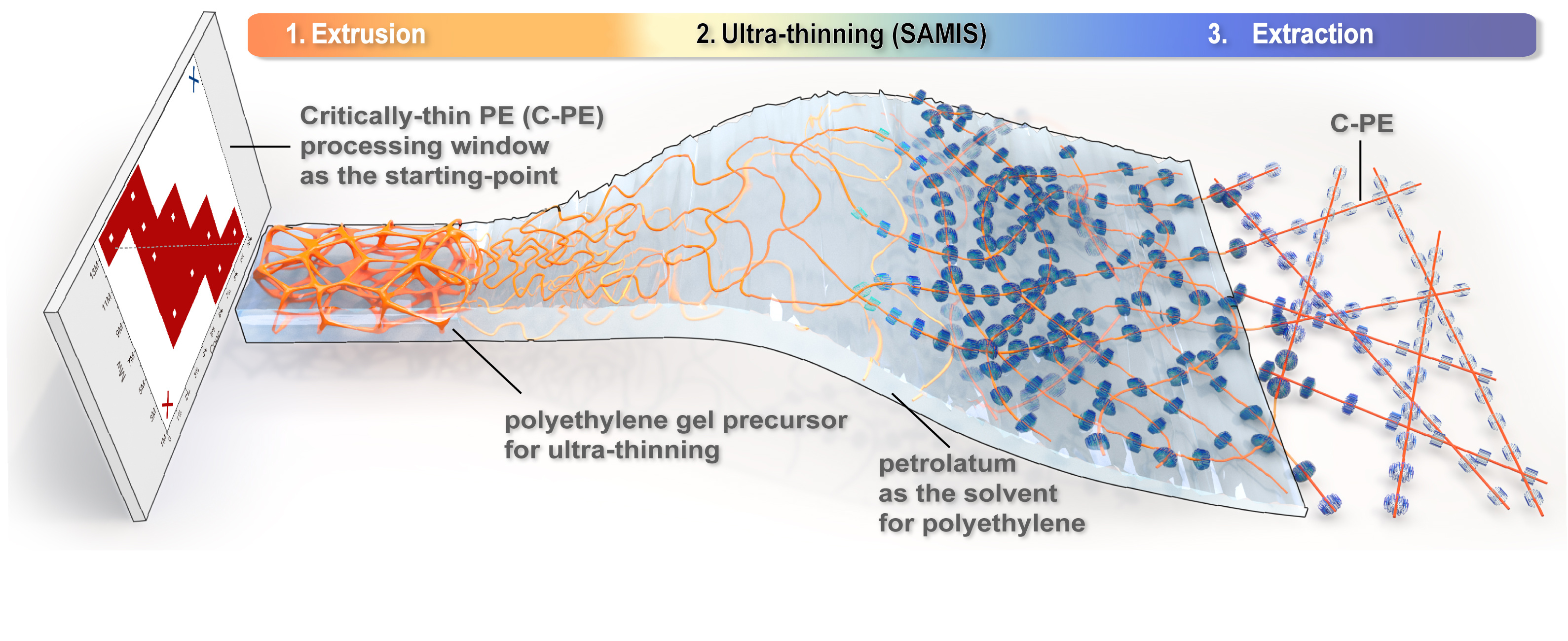

Using large-scale mechanical stretching combined with periodic relaxation—akin to dough-making techniques—Professor Fu's team tackled the dual challenge of processability and stability. Their innovative approach ensures molecular chain entanglements are optimized for stretching, enabling polyethylene films to reach their theoretical limit of thinness while spanning square-meter areas.

2. Unique Properties of C-PE

These critically thin polyethylene films are more than just thin; they exhibit extraordinary physical properties:

- Exceptional Mechanical Strength: Supporting weights 55,000 times their own, these films outperform traditional counterparts and rival advanced aerogels.

- Unusual Interfacial Behavior: Despite being hydrophobic, the films allow ink to pass through to a water bath below, a unique trait opening new possibilities in membrane separation.

- Self-Conformability: Their thinness enables these films to conform to surfaces naturally, ideal for wearable applications like epidermal sensors.

- Density-Specific Modulus: With a modulus of 113.9 GPa/(g/cm³), these films far surpass materials like stainless steel.

Figure 1. Critically thin polyethylene (C-PE) prepared in this work.

3. Applications on the Horizon

The innovations are not just academic; their impact spans industries. The films have potential use in breathable sensors, offering next-generation solutions in health monitoring. They are also being considered as critical support materials in nuclear fusion ignition, where precision and thinness are paramount.

This achievement is more than a milestone in polymer science. It reflects the philosophy of learning from diverse fields to solve complex problems. As the team continues to push the boundaries of material science, their work not only advances academic understanding but also offers scalable solutions for a sustainable future.

This study, titled "Scalable Production of Critically Thin Polyethylene Films via Multistep Stretching", is published in Nature Chemical Engineering. https://www.nature.com/articles/s44286-024-00139-w/metrics

Follow the Topic

-

Nature Chemical Engineering

This is a new monthly online journal dedicated to publishing the most significant original research, commentary and analysis of direct relevance to the diverse community of chemical engineers.

Ask the Editor – Polymers

Got a question for the editor about Functional polymers? Ask it here!

Continue reading announcement

Please sign in or register for FREE

If you are a registered user on Research Communities by Springer Nature, please sign in