Transparent sunlight-activated antifogging metamaterials

Published in Materials

The recent pandemic showed how bothersome the loss of visibility can be. Not only eyewear, but a wide range of application where transparency is crucial is affected by fogging. Current approaches to combat fogging rely on hydrophilic surface treatments. As superhydrophilic coatings are prone to contamination due to their high surface energy, they only work temporarily and require repeated reapplication. Guided by nucleation thermodynamics, we explored in our work a recent alternative pathway, which exploits the efficient and selective absorption of the abundant sunlight to induce photothermal heating and prevent fogging.

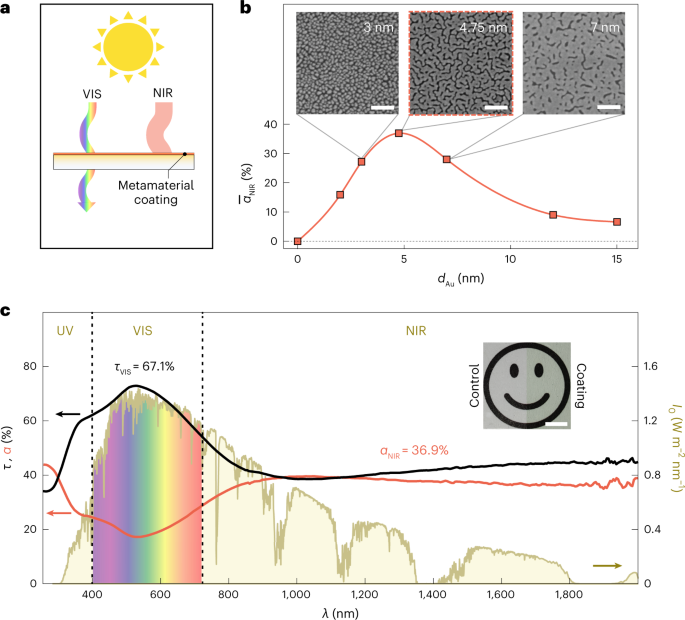

Interestingly, nearly half of the solar energy is in the near-infrared (NIR) range. For this reason, our coating design targeted a high broadband absorption in the NIR and yet retain the transparency in the visible (VIS) spectrum, as illustrated in Fig. 1a. The real-world applicability of our coating was very important to us; hence, we focused on a scalable, industrialized fabrication method and targeted a very thin coating. This would allow us to easily integrate our coating into or beneath additional standard coatings, rendering it durable and well-guarded from any outdoor influences.

For this, we first parametrically deposited a thin layer of gold, until we reached the optical percolation threshold. In this regime, the plasmonic resonance peaks experience a redshift, and a metallic Drude term also affects the absorption spectrum. As a result, at NIR wavelengths, the absorption reaches a broadband behavior with maximal absorption. We reached this threshold for a nominal deposition thickness of 4.75 nm, as shown in Fig. 1b. The resulting spectrum with high transmissivity in the visible regime and a broadband absorption in the NIR spectrum is shown in Fig. 1c.

We then tested our coating under controlled conditions on an experimental setup in our lab. First, we assessed the photothermal response upon solar irradiation corresponding to 1 sun. The coating showed a steady-state temperature increase of 8.3°C within less than 3 minutes. We also tested the coating under more realistic conditions with less irradiation to values corresponding to 0.2 suns. Even under these challenging conditions, the coating still performed well (> 2°C temperature increase above ambient).

As a next step, we quantified the impact of the photothermal response on the antifogging as well as defogging performance of the coating. Classical nucleation theory shows a very sensitive dependence of the condensate nucleation rate on temperature, and thus a small increase in temperature is expected to strongly decrease the probability of fogging. Indeed, our indoor experiments evidenced that the metamaterial coating leads to a nearly 4-fold improvement of the fog resistance compared to an uncoated control sample. Moreover, the transparency of a fully fogged coated sample is recovered by up to 3 times faster compared to the control.

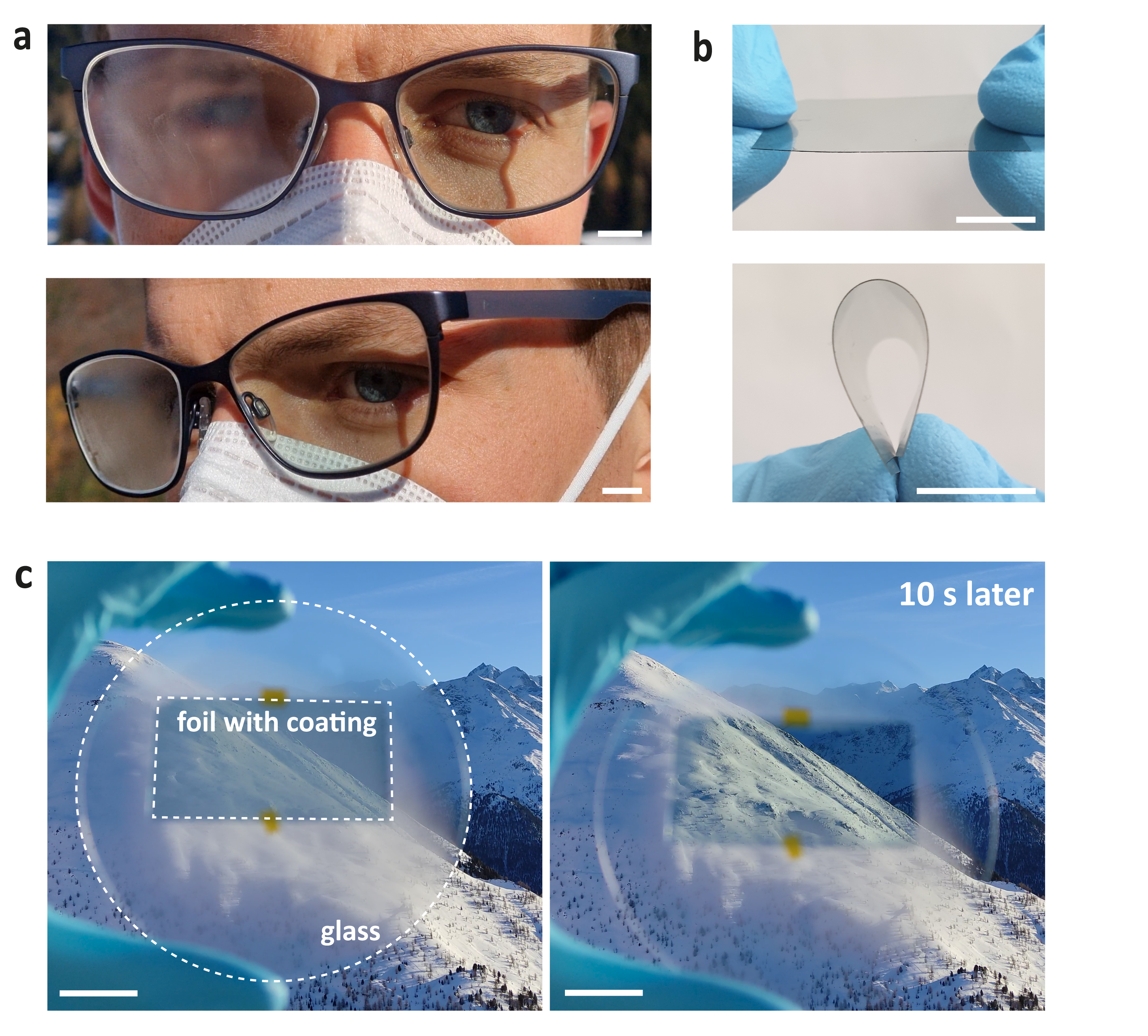

To verify the applicability of our coating, we deposited our coating onto a lens of a pair of prescription glasses. We then tested the antifog behavior of the coating in the Swiss mountains during winter, wearing a well-fitted face mask and exhaling. Clearly, Fig. 2a demonstrates how the coating retains the transparency, whereas the uncoated glass fogs.

The thinness of the coating allows it to be deposited onto a flexible substrate, as it is robust against serious repetitive deformation, as presented in Fig. 2b. This allows the coating to be retrospectively attached to an existing windowpane to prevent fogging. We tested this approach again under real-world conditions in the Swiss Alps at low solar intensity. For this, we taped a metamaterial-coated polyester sheet onto a silica wafer, exhaled several times onto it such that it fogged, before exposing it to the sunlight. After 10s of light exposure, the coating defogs completely and recovers the visibility, as illustrated in Fig. 2c.

To summarize, we developed an ultrathin metamaterial coating with a high VIS transparency and strong NIR absorption enabling it to passively and sustainably combat fogging through photothermal heating. The spectral selectivity with a broadening of the absorptivity in the NIR is achieved through a structural percolating effect of a metallic Au nanofilm. Due to its ultrathin (~10 nm) nature and its standard fabrication process, the coating can be easily upscaled, and has the potential to be applied over large areas, or be integrated into existing multilayer coatings, adding an antifogging functionality. Importantly, we show that the coating performs well even under more challenging conditions, such as illumination levels down to 0.2 suns.

Follow the Topic

-

Nature Nanotechnology

An interdisciplinary journal that publishes papers of the highest quality and significance in all areas of nanoscience and nanotechnology.

Please sign in or register for FREE

If you are a registered user on Research Communities by Springer Nature, please sign in