4D printing, an advanced technology within additive manufacturing (3D printing), introduces the fourth dimension—time. This innovation allows 3D-printed objects to transform their structure and shape over time in response to environmental stimuli. This cutting-edge 4D printing technique has significantly impacted the field of soft robotics. Despite its transformative potential, traditional polymers used in soft robotics often lack responsiveness to environmental cues, limiting the adaptability of soft robots across diverse surroundings and scenarios.

To address this limitation, incorporating rigid nanoparticles into soft robots emerges as a practical solution. Rigid nanoparticles bring excellent physical properties such as conductivity, photothermal responsiveness, and magnetism, enhancing the stimulus-response ability of soft robots. However, the integration of rigid nanoparticles into soft robots faces challenges. It can compromise the flexibility of soft robots and inevitably increase the mechanical hardness of materials, thereby restricting their shape recovery and deformation capabilities.

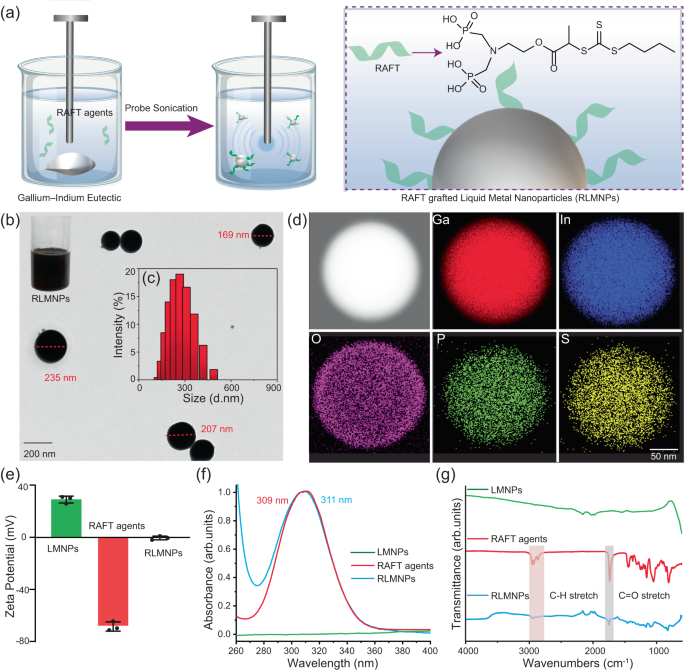

Liquid metal nanoparticles (LMNPs) represent a new category of soft nanomaterials endowed with unique mechanical and photothermal properties. Benefiting from these distinctive characteristics, we have developed a photoinduced electron/energy transfer reversible addition–fragmentation chain transfer polymerization (PET-RAFT) approach. This method enables the direct fabrication of polymer composites integrated with LMNPs, allowing for customized structures achieved through the 3D printing process (Figure 1). The soft nature of LMNPs contributes to reduced mechanical properties (glass transition temperature, storage modulus, tensile stress, and Young’s modulus) in 3D-printed composites, favoring the shape adaptability crucial for soft robots.

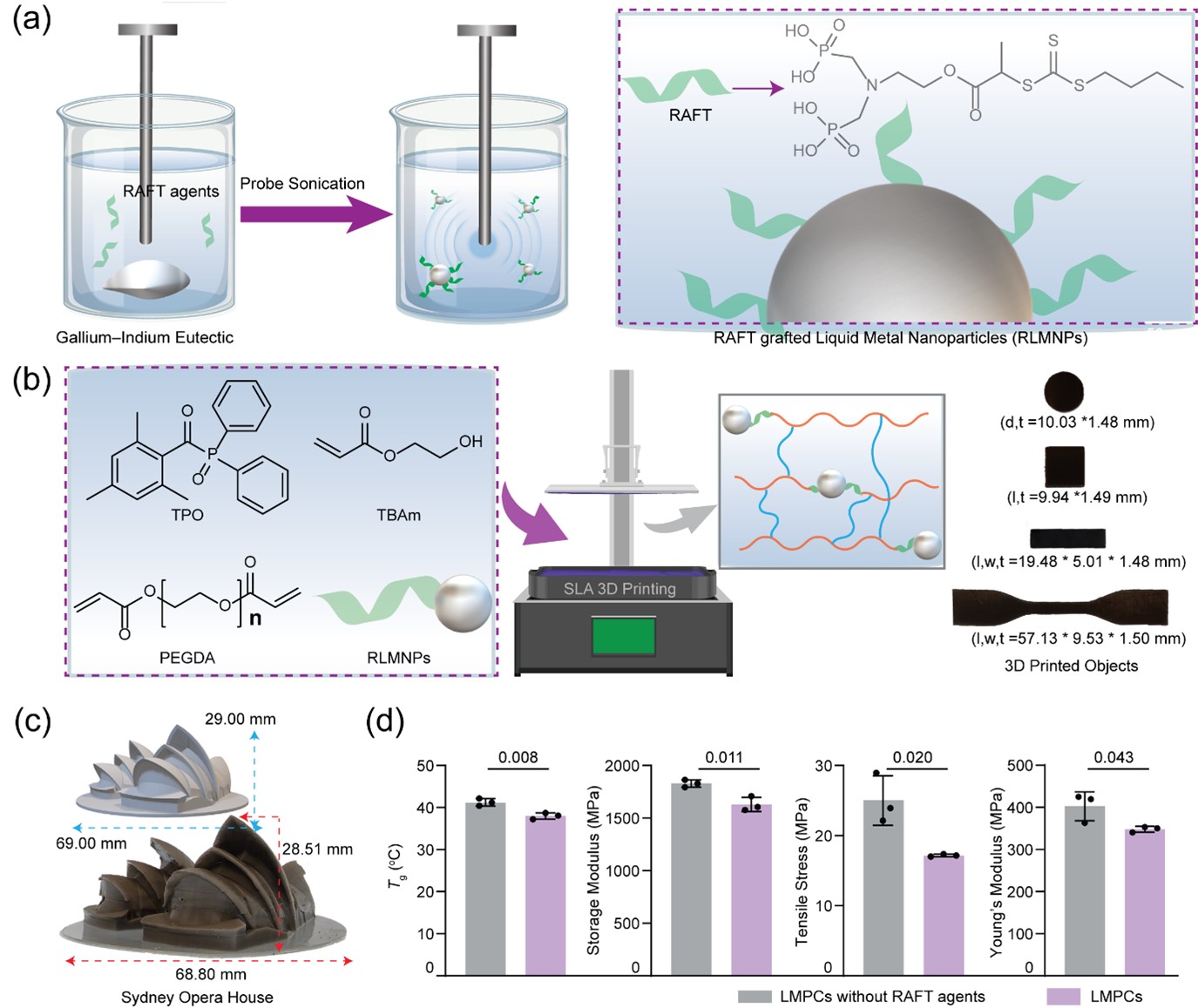

Figure 1. The revolution of liquid metal nanoparticles in additive manufacturing. (a) The fabrication of RLMNPs in an ethanol solution via ultrasonication; (b) The fabrication process of 3D-printed objects by using diphenyl (2,4,6-trimethyl benzoyl) phosphine oxide as photo-initiator, tert-butyl acrylate as the monomer, poly (ethylene glycol) diacrylate as a crosslinker. d,t, l, and w mean the diameter, thickness, length and width of the liquid metal polymer composites, respectively; (c) A model resembling the Sydney Opera House with liquid metal nanoparticles was manufactured using stereolithography 3D printing; (d) Mechanical properties of liquid metal polymer composites;

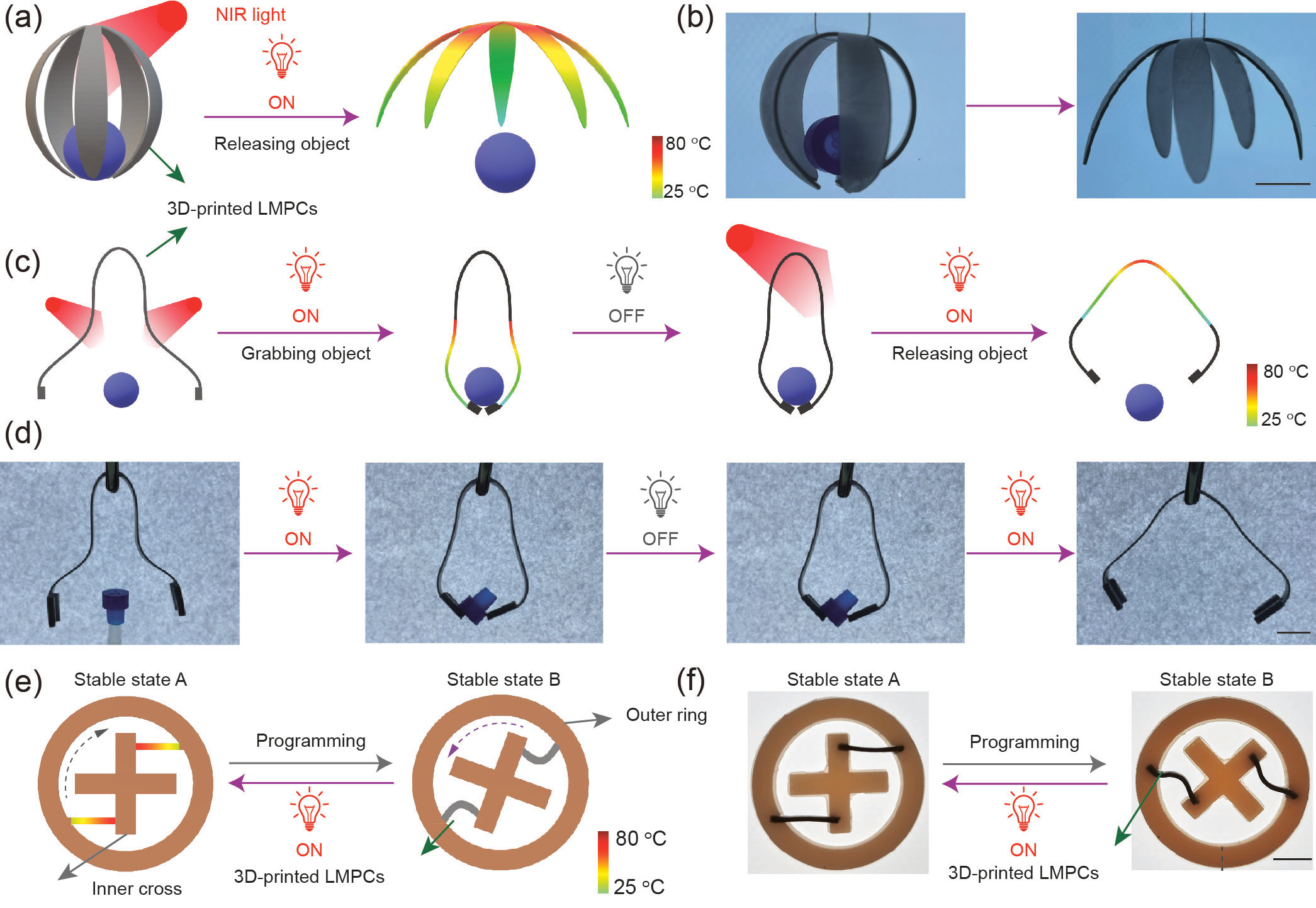

We then demonstrate the potential of 3D-printed LMNPs/polymer composites (LMPCs) as “soft robots” with shape memory properties under NIR light triggering (Figure 2). These composites exhibit remarkable efficiency in light-triggered 4D printing, swiftly and fully regaining pre-programmed shapes within 60 seconds of NIR light exposure. In addition, 3D-printed LMPCs serve as NIR-responsive soft robot that extends beyond mere grasping and releasing items, encompassing the additional capability to control rotational bistable structures.

Figure 2. Application of liquid metal nanoparticles in 4D-printed soft robots. (a) The diagram and (b) demonstration of releasing an object via NIR light responsive soft robots (c) The diagram and (d) demonstration of gripping and releasing an object via using NIR light controlled soft robots (e) The diagram and (f) demonstration of the rotated structure (state B) transforms into the original shape (state A) upon NIR exposure.

In summary, we successfully developed a versatile but simple method to integrate LMNPs into 3D-printed resins, creating high-resolution LM-polymer composites with reduced mechanical strength, excellent photothermal properties, and shape memory ability. It demonstrated exceptional repeatability, and advanced soft robot functionalities, heralding significant potential in robotics, medical tools, and actuators.

For more details, please refer to our paper recently published in Nature Communications:

3D-printed liquid metal polymer composites as NIR-responsive 4D printing soft robot.

Liwen Zhang, Xumin Huang, Tim Cole, Hongda Lu, Jiangyu Hang, Weihua Li, Shi-Yang Tang*, Cyrille Boyer, Thomas P. Davis* & Ruirui Qiao*.

Nature Communications, 2023, 14, 7815

Please sign in or register for FREE

If you are a registered user on Research Communities by Springer Nature, please sign in