Additive Manufacturing of Composites—Without the Support, the Oven, or the Wait

Published in Materials and Mechanical Engineering

Carbon fiber composites are widely recognized for their exceptional mechanical performance, particularly their ability to provide high strength and stiffness while remaining lightweight. However, despite their widespread use in high-performance applications, fabrication remains constrained by conventional manufacturing methods that are labor-intensive, tooling-dependent, and energy-demanding. Traditional processes involve placing layers of fiber and resin, either by hand or machine, on custom molds, followed by thermal curing in ovens or autoclaves. These steps are costly, time-consuming, and fundamentally inflexible. They not only increase production costs and lead times but also restrict design freedom and scalability. The fixed geometry of molds limits iteration, and the need for oven-based curing imposes energy burdens and size constraints. For broader adoption, particularly in applications that require rapid prototyping or distributed manufacturing, a fundamentally different approach is needed.

Toward Scalable, Agile Composite Manufacturing

Inspired by the transformative impact of additive manufacturing on polymers and metals, we aimed to bring similar flexibility and efficiency to fiber-reinforced composites. Our goal was to develop a method that enables geometric freedom, on-demand fabrication, and automated processing, without compromising structural performance.

A core bottleneck in additive manufacturing of composites lies in the resin solidification step. Some current systems rely on UV-curable thermosetting resins. Thermosets are a class of polymers that begin as liquids and irreversibly harden into strong, durable solids when cured (a process in which chemical bonds form between polymer chains, creating a rigid, crosslinked network). UV-curable resins enable fast surface-level curing during printing but often require a secondary thermal post-cure to achieve full crosslinking and optimal mechanical properties. This added step extends the production timeline and reintroduces the need for ovens, which is especially problematic for large or structurally critical parts, thus limiting scalability. Thermoplastic composites, while appealing due to their melt-processability and potential for recycling, present their own challenges, including high processing temperatures, limited interlayer bonding, and difficulty achieving high fiber volume fractions or intricate geometries. As a result, neither approach fully overcomes the trade-offs between processing speed, structural quality, and manufacturing flexibility.

Our work addresses these limitations by enabling spatially controlled, in-situ thermal curing of thermosetting composites using low-power energy sources, eliminating the need for molds and post-curing infrastructure while preserving material integrity and manufacturing agility.

Controlled, Localized Curing During Deposition

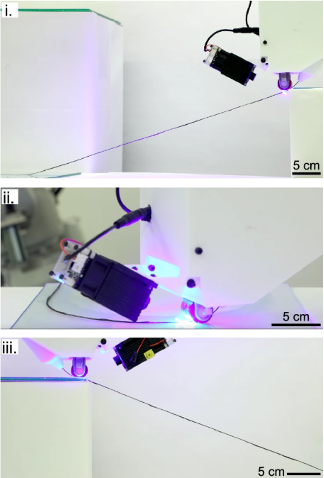

This work introduces a composite additive manufacturing process that uses localized thermal energy delivered via a low-power laser to enable in-situ curing of a rapidly heat-curable resin during printing. By decoupling the curing mechanism from the surrounding environment and applying energy precisely where and when it is needed, the process offers fine-grained spatial and temporal control over polymerization. This capability supports not only conventional layer-by-layer printing on a substrate but also freeform, midair deposition without the need for support structures (Figure 1). As a result, complex geometries can be fabricated without molds or ovens, significantly enhancing the flexibility, scalability, and energy efficiency of composite part production.

We began by formulating a composite ink consisting of discontinuous (chopped) carbon fibers dispersed in a thermosetting resin. By optimizing laser parameters, deposition speeds, and fiber-resin ratios, we demonstrated that the process could achieve cure-on-deposition at print speeds up to 1.5 m/min, with void content below 1.5%, and mechanical properties comparable to those of traditionally molded and oven-cured composites.

Transition to Continuous Fiber Reinforcement

While chopped fiber composites offer useful properties, continuous fiber reinforcement is critical for maximizing load-bearing capability. Transitioning to continuous fiber deposition introduced additional challenges in fiber handling, deposition stability, and ensuring consistent in-situ cure. Nonetheless, we were able to adapt the process with minimal changes to the hardware. The system successfully printed continuous carbon fiber composites with high fiber volume fractions (up to 70%) and strong interlayer adhesion. Importantly, the mechanical performance of these parts remained comparable to conventionally manufactured composites, validating both the material formulation and the integrated thermal curing approach.

Geometric Freedom Through Robotic Deposition

One of the most compelling outcomes of this work was the integration of the process with a 6-axis robotic arm (Figure 2). By enabling precise, programmable control over the location and timing of cure, the system supports freeform fabrication without the need for support structures or molds.

This capability unlocks true out-of-plane composite printing. The ability to deposit and cure material in midair, unconstrained by tooling, enables the creation of architecturally complex structures that are otherwise difficult or impossible to produce using traditional layup and curing techniques. Moreover, the low thermal footprint of the process (requiring only a 4.5 W laser) reduces energy consumption by several orders of magnitude compared to oven-based methods, enhancing both the sustainability and field-deployability of the approach.

Looking Ahead

This work demonstrates a practical, scalable method for additive manufacturing of high-performance composites using both discontinuous and continuous fiber reinforcement. By removing the need for large-scale thermal infrastructure and rigid tooling, our approach significantly lowers the cost, time, and energy barriers traditionally associated with composite part fabrication.

Future efforts will focus on scaling the process and expanding the material set. We are also investigating applications in large-scale structural components, particularly in aerospace, defense, and energy sectors, domains where agility, lightweighting, and geometric versatility are essential.

Follow the Topic

-

Nature Communications

An open access, multidisciplinary journal dedicated to publishing high-quality research in all areas of the biological, health, physical, chemical and Earth sciences.

Related Collections

With Collections, you can get published faster and increase your visibility.

Women's Health

Publishing Model: Hybrid

Deadline: Ongoing

Advances in neurodegenerative diseases

Publishing Model: Hybrid

Deadline: Mar 24, 2026

Please sign in or register for FREE

If you are a registered user on Research Communities by Springer Nature, please sign in