Behind the paper: Greener hybrid polypropylene composites using flax, basalt and rice husk powder

Published in Materials

Polypropylene (PP) is everywhere—from packaging to consumer goods—because it is lightweight, affordable, and easy to process. But “plain PP” can fall short when parts need higher stiffness, better strength, or improved thermal performance. A common solution is glass fibre, yet that increases density and can complicate end-of-life choices. In this study, we asked a practical question: can we push PP into a higher performance window using a hybrid, greener reinforcement strategy that still fits standard compounding and injection-moulding workflows?

We designed a hybrid system with three complementary ingredients. First, short woven flax fibre (SWF) as a renewable reinforcement. Second, short basalt fibre (BF) as a mineral reinforcement with high rigidity and thermal robustness. Third, rice husk powder (RHP) as an abundant agro-waste filler that is widely available and often under-utilized. The fourth (and arguably most important) ingredient was a coupling agent: maleic-anhydride-grafted polypropylene (MAPP). The motivation was simple: hybrid composites can look promising on paper, but without strong fibre–matrix and particle–matrix adhesion, the “hybrid” becomes just a mixture—stiffer perhaps, but not reliably stronger, and often more brittle or defect-prone.

From the start, we kept the manufacturing route industry-friendly: twin-screw extrusion to compound the ingredients, followed by injection moulding to form specimens. That choice was deliberate. Sustainability claims do not help if a material cannot be compounded and shaped reliably at scale. In practice, processing hybrid bio-/mineral-reinforced PP is a balancing act. Increasing reinforcement content generally improves stiffness, but it can reduce ductility, increase melt viscosity, and raise the risk of agglomeration or fibre damage during compounding. We treated this as an engineering problem rather than a “maximum loading” challenge: the goal was to find a formulation space where the material is improved, processable, and stable.

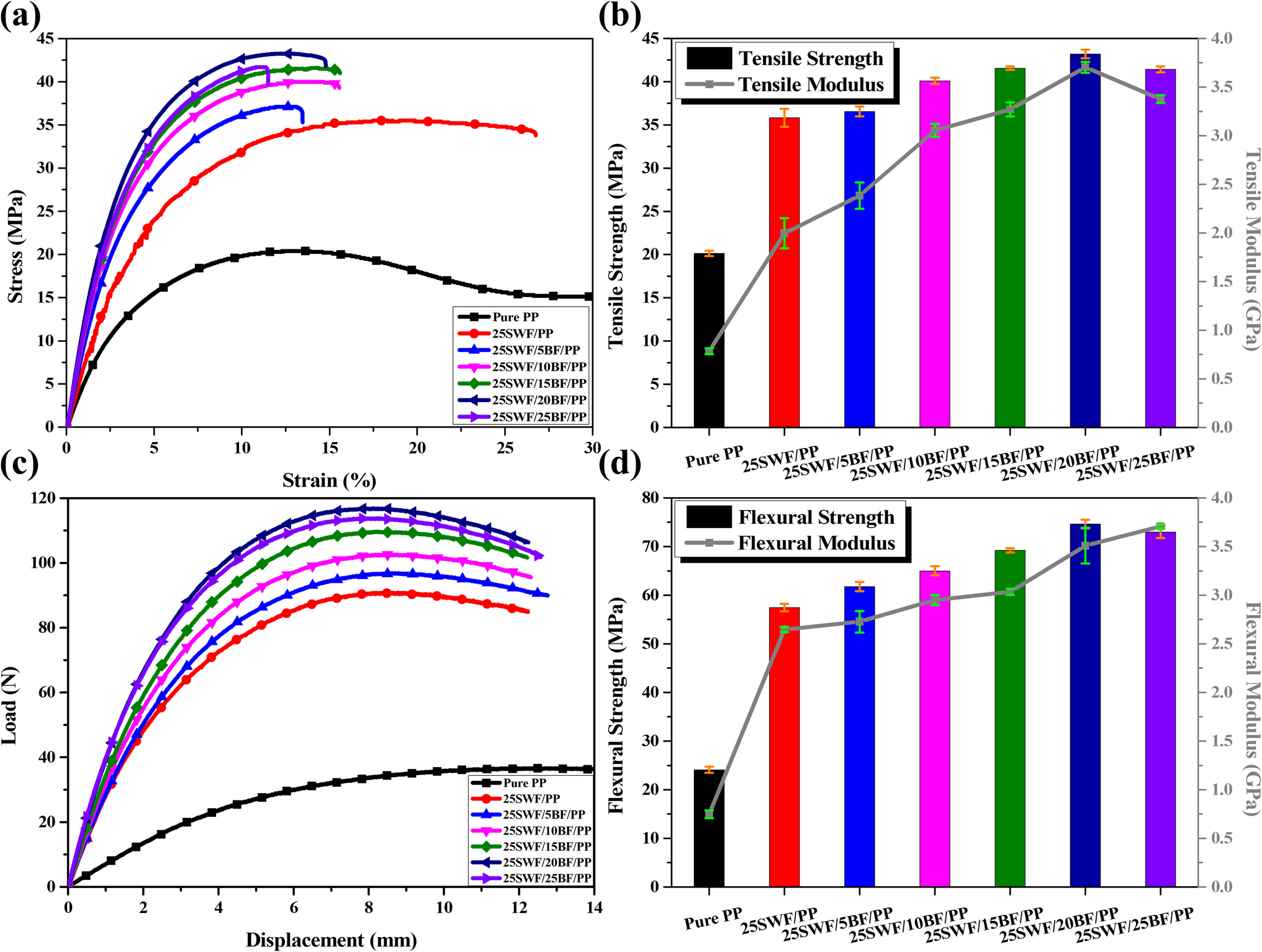

What surprised us most was how strongly the interface governed the final performance. When MAPP was introduced, the improvement was not marginal—it was decisive. Tensile strength increased from 35.82 to 56.48 MPa (a 57.68% rise), and tensile modulus increased from 2.00 to 4.94 GPa (146.6%). Flexural strength increased by 21.93% (reaching 92.05 MPa), and flexural modulus improved by 157% (to 4.22 GPa). In dynamic mechanical analysis, the storage modulus increased substantially (up to 266%), reinforcing the idea that the hybrid architecture can deliver meaningful stiffness gains over a wider range of conditions, not only in a single static test.

Thermal behaviour told a consistent story. In TGA, the char residue at 700 °C increased from 2.22% for neat PP to 16.81% for the compatibilized hybrid composite. This is a large shift in decomposition outcome, suggesting that the hybrid reinforcement plus coupling strategy can promote more stable residue formation at high temperature. Practically, this matters for applications where thermal stability, thermal aging, or post-decomposition residue are part of the performance requirements.

Behind these numbers is a materials-engineering message that is easy to overlook: hybridization is not simply “adding more types of fillers.” Each reinforcement plays a different role, but the system only works as a system if the load can move across interfaces. Flax can provide good specific properties and lower embodied impact, but it is moisture-sensitive and tends to debond from PP without compatibilization. Basalt brings high stiffness and thermal robustness, helping the composite carry load even when natural fibres alone are not enough. Rice husk powder can stiffen the matrix and contribute to thermal residue, but if it is poorly bonded or poorly dispersed, it can act as a stress concentrator rather than a reinforcing phase.

MAPP acts like the “translator” among these phases. By improving compatibility between PP and polar fibre/filler surfaces, it strengthens stress-transfer pathways that otherwise fail early. In practice, that means the same hybrid concept can swing from “stiff but weak and brittle” to “stiff and strong enough to be useful,” simply by engineering the interface. This is why we believe coupling-agent-assisted hybridization is scalable: the approach fits common compounding equipment, it does not require exotic processing, and it addresses a root cause of performance loss in bio-filled PP systems—interfacial inefficiency.

We also tried to support this interpretation with more than one measurement. Mechanical testing (tensile and flexural) tells you what the composite can do under load. DMA adds a temperature-dependent stiffness view that is closer to service behaviour. TGA provides a decomposition-level picture of thermal stability and residue. Morphology and chemistry tools (FTIR and SEM–EDS) help check whether microstructural evidence plausibly explains the property changes. Looking across these methods helped us avoid a common trap: reporting a single property improvement without confirming whether it comes from true reinforcement, better interfacial bonding, or an artefact of poor baseline comparisons.

If you work in compounding or product design, the practical takeaway is straightforward. If you want greener PP composites that combine bio-based fibres and agro-waste fillers, treat the interface as a first-class design variable. Without compatibilization and dispersion control, adding more filler can hurt more than it helps. With MAPP and a sensible hybrid balance, you can gain stiffness, strength, and thermal residue while staying within familiar extrusion and injection-moulding workflows.

Where can this go next? Two directions stand out. The first is durability: moisture aging, thermal cycling, and fatigue are critical for natural-fibre systems, and they should be assessed alongside “as-made” mechanical properties. The second is application-driven optimization: hybrid PP composites can be tuned for different property packages (stiffness-dominated vs. strength-dominated vs. residue-dominated), and that tuning can be guided by microstructure-aware processing control and data-driven formulation screening.

If you are curious about the detailed formulations, processing, and characterization results, you can read the full article here: https://doi.org/10.1007/s42114-025-01277-2

Follow the Topic

-

Advanced Composites and Hybrid Materials

Advanced Composites and Hybrid Materials is a single-blind peer-reviewed journal focused on composites and nanocomposites, their design, modeling, advanced manufacturing, interface engineering technologies and applications.

Ask the Editor – Polymers

Got a question for the editor about Functional polymers? Ask it here!

Continue reading announcement

Please sign in or register for FREE

If you are a registered user on Research Communities by Springer Nature, please sign in