Portland-cement-based concrete is indispensable in construction, yet its production is a significant source of CO2 emissions, accounting for 5-8% of global emissions. While renewable energy can mitigate energy-related emissions, process emissions from limestone calcination remain a challenge. Bio-concrete, utilizing microbially-induced calcium carbonate precipitation (MICP), offers a CO2-negative alternative by sequestering carbon in carbonate compounds. Now a new study by Maiia Smirnova and colleagues addresses the limitations of bio-concrete's compressive strength and component depth, aiming to make it a viable replacement for traditional concrete.

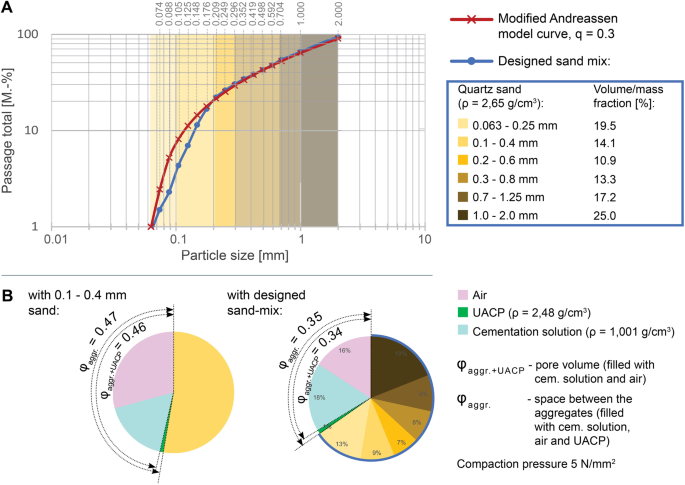

Smirnova et al.'s research represents an experimental study that systematically explores the optimization of bio-concrete through MICP. The team employed ureolytic bacteria to catalyze calcium carbonate formation, embedding these bacteria within a "bioslurry" to enhance retention during cementation. This innovative approach retained approximately 90% of urease activity, crucial for the biomineralization process. The study tested various sand fractions to optimize aggregate packing density using the Elkem Material Mix Analyser software and the Modified Andreassen model. The optimized mix demonstrated higher aggregate packing density and reduced porosity, which are key to achieving higher compressive strength.

The researchers conducted biomineralization experiments using an automated pressure-based cementation system, allowing precise control over the flow rates of the cementation solution. They varied parameters such as pressure and concentration to assess their impact on cementation depth and strength. The study involved extensive testing with different UACP (urease-active calcium carbonate powder) contents and supply pressures to identify optimal conditions for homogeneity and strength.

The results were promising: specimens exhibited unconfined compressive strength values exceeding 50 MPa with sufficient cementation depth, surpassing previous benchmarks in bio-concrete research. The study also highlighted the importance of maximizing aggregate content and optimizing cementation parameters for improved performance.

Summarizing their findings, Smirnova et al. conclude that by maximizing aggregate packing density and fine-tuning cementation parameters, bio-concrete can achieve compressive strengths comparable to traditional concrete. Their method produced homogeneously cemented specimens with strengths up to 50 MPa—potentially meeting requirements for prefabricated structural elements. This advancement in bio-concrete technology could lead to its application in standardized building components, contributing to more sustainable construction practices.

Future work may focus on scaling up production while addressing environmental challenges associated with raw material sourcing and effluent recycling—paving the way for carbon-neutral bio-concrete production on a larger scale.

This text on an editorially selected paper was initially drafted using artificial intelligence, and then fact-checked and improved by an editor to meet Springer Nature publication standards.

Follow the Topic

-

npj Materials Sustainability

This is an open access, transdisciplinary journal presenting high-quality research that advances the scientific understanding and engineering design of materials with respect to the sustainability of their production, use and re-use.

Related Collections

With Collections, you can get published faster and increase your visibility.

Technology-Critical Metals/Minerals

Publishing Model: Open Access

Deadline: May 31, 2026

Environmental Impact of Sustainable Materials

Publishing Model: Open Access

Deadline: Apr 30, 2026

Please sign in or register for FREE

If you are a registered user on Research Communities by Springer Nature, please sign in