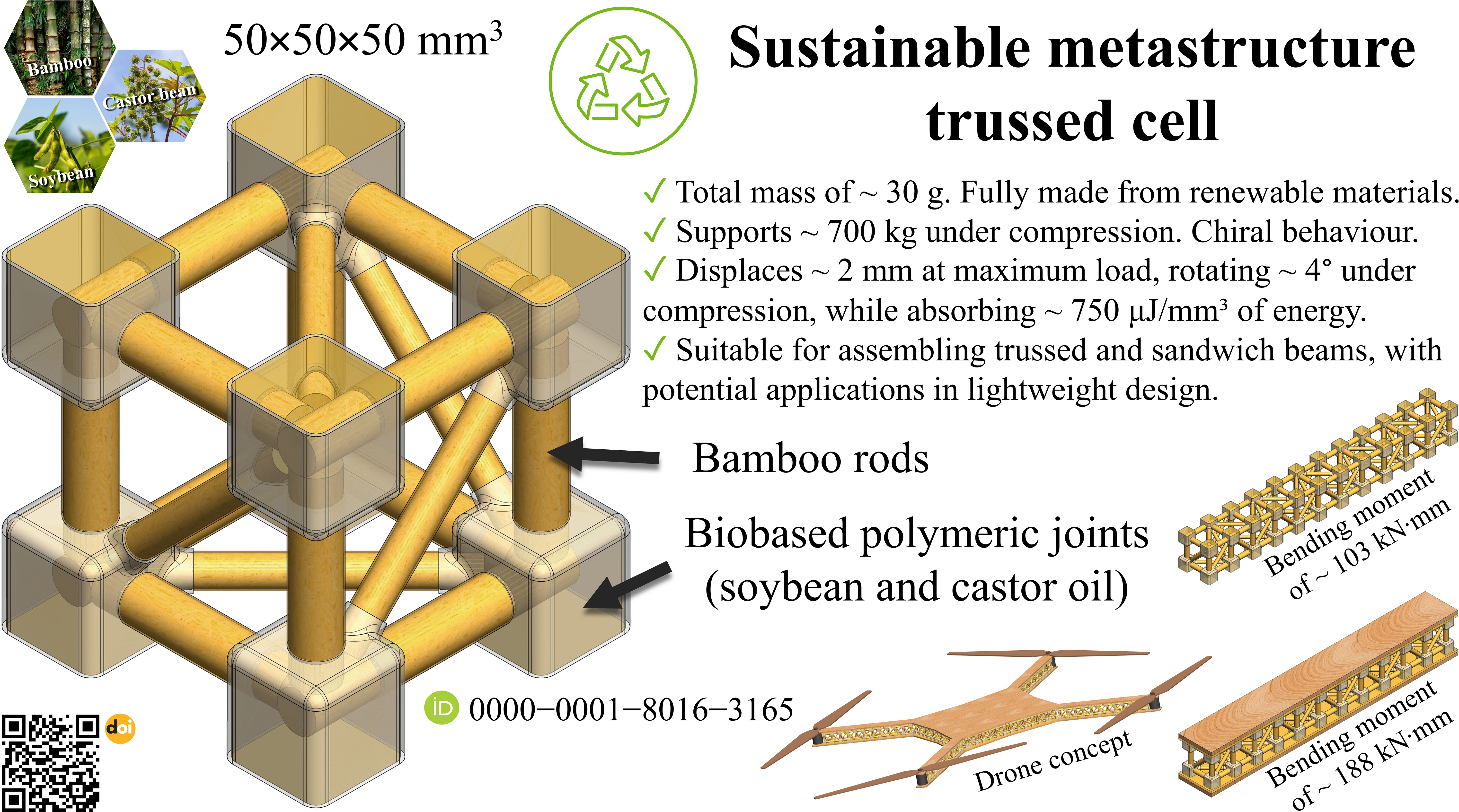

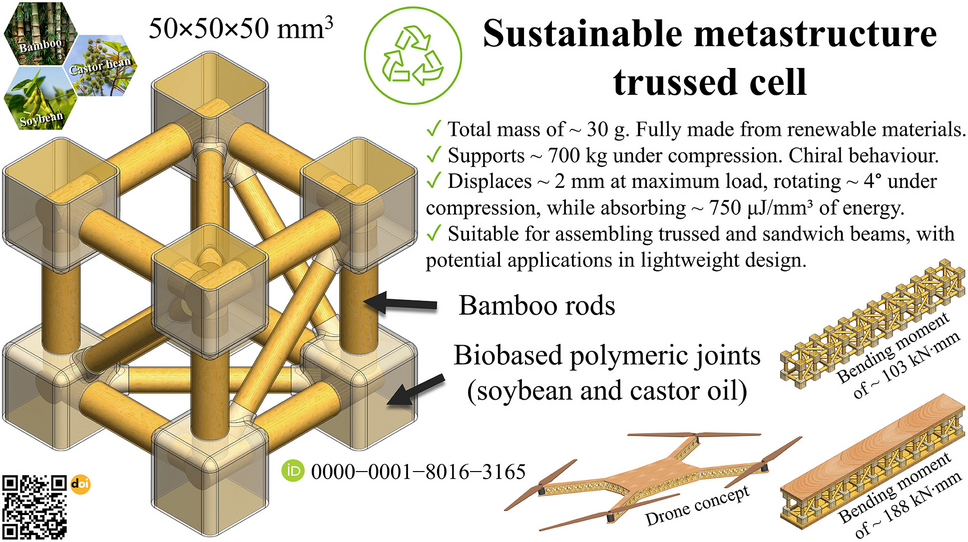

Building the future with bamboo: a fully bio-based metastructure for modular composite design

Published in Materials, Sustainability, and Mechanical Engineering

How do you turn raw bamboo rods into a high-performance metastructure that supports 700 kg while weighing just 30 grams, and do it with 100% bio-based materials?

It starts in the field (with the natural hierarchy of bamboo, a plant optimised by evolution for strength-to-weight ratio and carbon sequestration) and ends in the lab, with a modular trussed cell engineered from sustainable polymers and bamboo rods. This story is about that journey: how materials science, geometry, and environmental stewardship came together to build something new.

Our research explores a fully bio-based composite metastructure, combining bamboo rods with polymeric joints derived from soybean and castor oils. The resulting cubic unit (just 50 mm per side) is designed to exhibit chiral rotation under compression, absorbing energy while remaining lightweight, stiff, and modular. Multiple cells are assembled into trussed beams and sandwich beams, creating scalable structures ranging from civil to aerospace applications.

🌿 From Bamboo Plant to Structural Component

In a previous study (RJS et al., 2025), we mechanically characterised rods extracted from the proximal section of the giant bamboo (Dendrocalamus asper), identifying the optimal culms for rod manufacturing. This work laid the foundation for our current design, which uses cylindrical rods drawn from prismatic bamboo segments.

Each modular cell consists of:

- 12 main bamboo rods (6 mm diameter) forming cube edges

- 6 auxiliary rods (4 mm diameter) forming face diagonals

- Polymeric joints, with outer shells printed in soybean resin and filled with castor oil-derived polyurethane for anchoring

This configuration was engineered for optimal load transfer and minimal redundancy. And because of the angled diagonals, the entire cell rotates under compression, exhibiting chiral behaviour and energy absorption, similar to Kresling origami structures.

Despite weighing just ~30 g, each cell withstands up to 700 kg in compressive loading, with only ~2 mm displacement and ~4° of rotation. The structure’s force-displacement slope reaches ~4,200 N/mm in the elastic regime. Mechanical testing revealed excellent performance in strength, stiffness, and resilience, while finite element analysis validated these behaviours and simulated torsional response (~7,300 N·mm per degree of twist).

🧱 Scaling Up: Trussed Beams and Sandwich Structures

By linking multiple cells in series, we built:

- A trussed beam (400 mm) composed of mirrored cells for balance

- A sandwich beam using balsa wood skins bonded to the trussed core

Each configuration was tested under four-point bending. The trussed beam reached ~2,000 N load capacity with a bending moment of ~103 kN·mm; the sandwich beam hit ~3,600 N and ~188 kN·mm, showing enhanced toughness and energy absorption due to better stress distribution. Finite element models were built to simulate elastic deformation, stress distributions, and cantilever bending.

🛰️ Where It Goes from Here

This research represents a step forward in designing sustainable composite structures for civil construction, aerospace, and possibly even modular drone applications. The trussed beam is scalable, and the metastructure cell can be adapted with alternate materials, geometries, and mechanical responses.

We're continuing this journey by exploring vibration transmissibility, scale effects, alternate skin materials, and automated fabrication techniques to improve efficiency and reduce cost. The ability to build strong, lightweight structures entirely from renewable components isn’t just a technical achievement; it’s a philosophical one.

It’s about rethinking engineering through the lens of nature, optimising geometry and material design together, and honouring sustainability from concept to final assembly.

Follow the Topic

-

Advanced Composites and Hybrid Materials

Advanced Composites and Hybrid Materials is a single-blind peer-reviewed journal focused on composites and nanocomposites, their design, modeling, advanced manufacturing, interface engineering technologies and applications.

What are SDG Topics?

An introduction to Sustainable Development Goals (SDGs) Topics and their role in highlighting sustainable development research.

Continue reading announcement

Please sign in or register for FREE

If you are a registered user on Research Communities by Springer Nature, please sign in