Can Nanomagnetic-Based Cementitious Material Seal Cracked Rocks?

Published in Earth & Environment and Civil Engineering

Rock crack cementing/sealing is important in earth engineering applications, where it is used to inject grout (cementitious materials) into cracks and voids in rocks (located either on the surface or in underground). This process enhances hydraulic properties, provides greater strength, reduces permeability, and improves overall rock stability. Cementitious materials can be used to fill the cracks and openings in rocks to improve their bonding/sealing efficiency, thus enhancing the overall strength of the rock and preventing anti-seepage. Currently, advancements in cementing technologies have introduced innovative methods, which include using nanoparticles, cementitious materials, and chemical cementitious materials, as effective solutions for this purpose. However, because of the limitations of traditional cementitious materials, such as limited resistance to dispersion, inadequate bonding properties, inconsistent mixture design and viscosity, injection pressure, and in-situ stress, an alternative method for in-filling of underground rocks containing cracks and openings is necessary. To address these issues, we developed and proposed a novel nanomagnetic-based cementitious material (which contains nanomagnetic powder, fly ash, and epoxy resin) and used the proposed nanomagnetic-based cementitious materials to fill cracks in rocks, and further assessed if it can seal and improve the strength of the cracked rocks for geo-engineering and underground infrastructure projects. This will inform the civil engineering community if the material has the potential to enhance the hydraulic properties, reduce permeability, and improve the overall mechanical stability of cracked rocks.

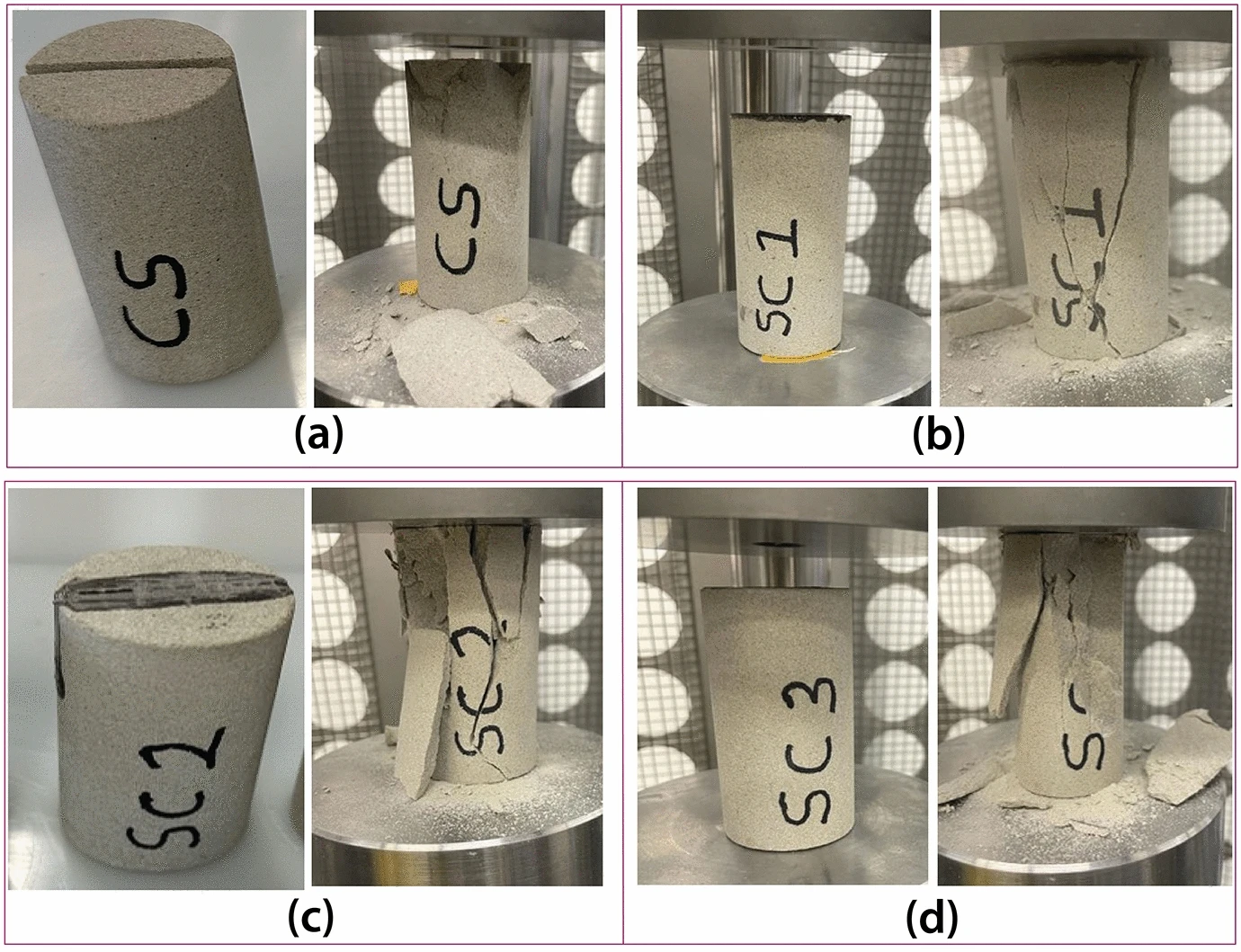

The result consists of evidence from flow performance tests, rock density, micro-scale imaging, and strength quantification. The flow performance test revealed distinct variations in the flow rates of the nanomagnetic cementitious material mixtures, highlighting the impact of different proportions of nanomagnetic powder and fly ash. The mixture with 15% nanomagnetic powder (MS1) showed an intermediate flow rate, while the mixture with 35% nanomagnetic powder (MS2) had the lowest flow rate. The mixture with 55% nanomagnetic powder (MS3) achieved the highest flow rate. These results indicate that the flowability of the nanomagnetic cementitious material is influenced by the ratio of nanomagnetic powder to fly ash in the mixture. The study also measured the rock density of both pre-treatment and post-treatment core samples. The results showed an increase in rock density after treatment, suggesting a reduction in void space within the rocks and occlusion of the cracks. This increase in density indicates that the nanomagnetic cementitious material effectively filled and bonded the cracks, creating a denser structure. Scanning Electron Microscopy (SEM) analysis was used to evaluate the microstructure of the rock samples before and after treatment. The SEM images revealed that the untreated rock samples had distinct mineral grains with capillary pore spaces. After cementing, the rock surface was covered with the hardened cementitious material, and the mineral grains were embedded within the cementitious material matrix. This observation suggests that the nanomagnetic cementitious material effectively penetrated and adhered to the crack surfaces, enhancing the bonding strength.

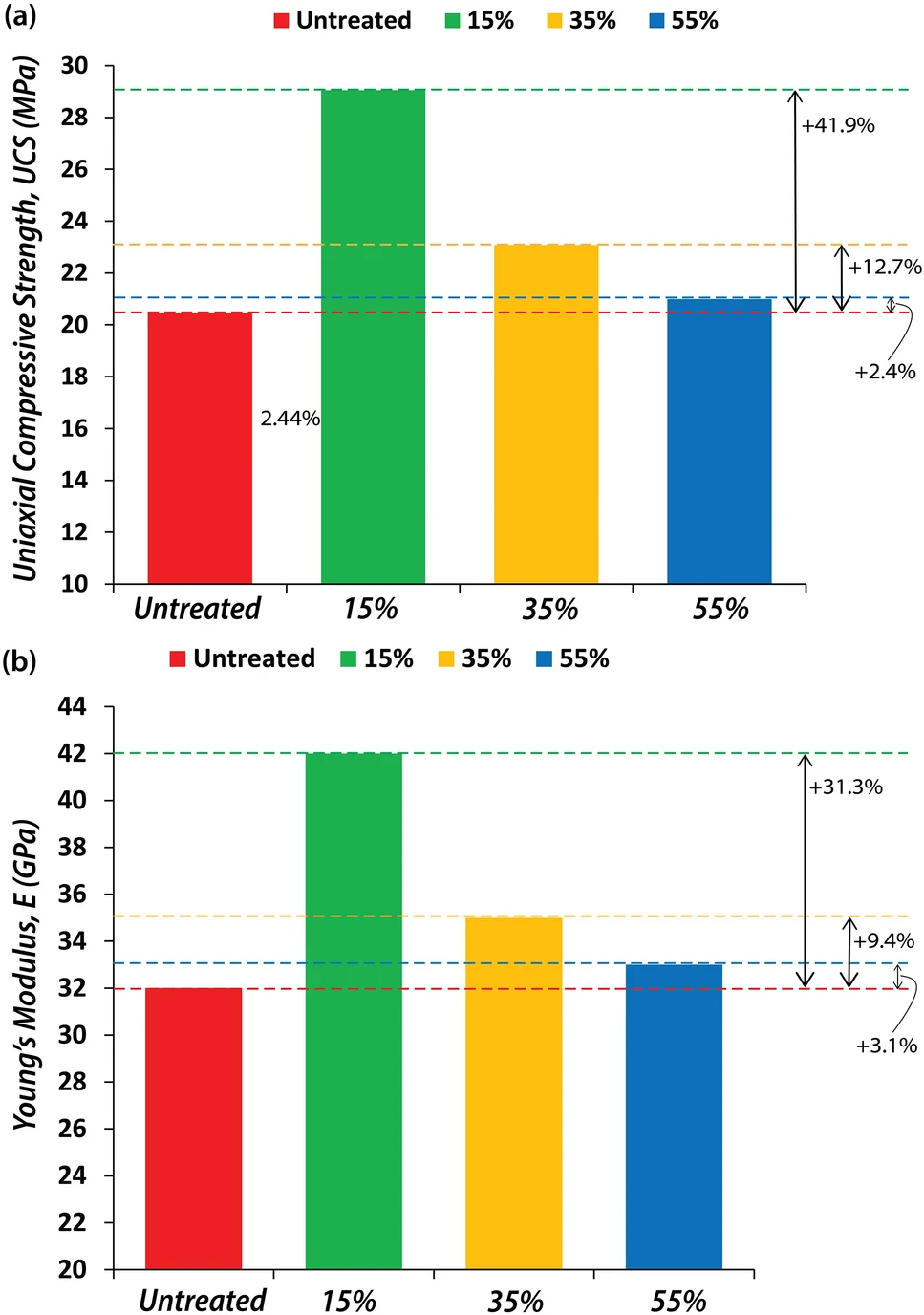

The mechanical properties of the rock samples were assessed using uniaxial compression tests. The results showed that the uniaxial compressive strength (UCS) and Young's modulus (E) of the treated rock samples improved significantly compared to the untreated samples. The mixture with 15% nanomagnetic powder (MS1) yielded the highest strength and stiffness, indicating that this composition provided the most effective reinforcement. The UCS of the treated samples increased by up to 41.9%, and the stiffness improved by up to 31.3%. The study concludes that the nanomagnetic cementitious material is an effective, eco-friendly alternative to traditional cement-based materials. The optimal mixture, containing 15% nanomagnetic material, enhances the rock's density and mechanical properties, making it more resistant to deformation and failure. The nanomagnetic cementitious material offers several advantages, including improved flowability, better bonding strength, and increased durability. Additionally, the use of nanomagnetic materials and fly ash contributes to the sustainability of the cementing process, reducing the environmental impact compared to traditional cement-based slurries.

Overall, the research provides new insights into the development of advanced rock-cementing materials for reinforcing cracked rocks. The findings suggest that the nanomagnetic cementitious material can significantly improve the stability and strength of rock formations, making it a promising solution for geo-engineering and underground infrastructure applications. The study highlights the potential of nanomagnetic cementitious material to enhance the performance of rock-binding operations, offering a sustainable and effective alternative to traditional methods.

Follow the Topic

-

Discover Civil Engineering

This is a fully open access, peer-reviewed journal that supports multidisciplinary research and policy developments across the field of civil engineering.

Related Collections

With Collections, you can get published faster and increase your visibility.

Innovations in Timber Engineering: Advancements in Sustainable Design, Connection Techniques, and Durability

The global timber construction sector is growing due to its sustainability, carbon sequestration, cost-effectiveness, technological advancements like engineered wood, supportive regulations, and market demand for green buildings. In response to these trends, research is focusing on alternative connection techniques and engineered wood products to enhance performance and sustainability. New methods are being developed to reduce reliance on steel and adhesives, aiming to improve reusability and fire resistance of timber structures. Dowel laminated timber (DLT) and timber dowel connections exemplify these innovations, offering promising solutions for modern construction needs.

This Topical Collection invites contributions exploring these emerging fields as well as novel approaches to traditional timber connections and products. It seeks to showcase advancements in engineered wood products and joint systems, highlighting their impact on timber structure design and performance. Additionally, the issue will delve into the durability characterization and modeling of timber products and assemblies, providing a comprehensive overview of current research and future directions. Contributing authors will work alongside the editors to compile a collection of articles that address these themes, offering valuable insights into the evolving landscape of timber engineering.

Keywords: Timber constructions, Sustainability, Connections, Fire resistance, Durability characterization, Dowel laminated timber.

Publishing Model: Open Access

Deadline: May 31, 2026

Advancements in Composite Materials for Civil Engineering Structures

Composite materials have revolutionized the field of civil engineering, offering innovative solutions for enhancing the strength, durability, and performance of structures. This topical collection focuses on the latest advancements in the application of composite materials, including cementitious composites, fiber-reinforced polymers, and fiber-reinforced concrete. These materials are increasingly being utilized to address challenges such as load-bearing capacity, environmental sustainability, and resistance to harsh conditions.

We welcome original research articles, case studies, and reviews that explore the design, production, and implementation of composite materials in civil engineering applications. Topics of interest include but are not limited to, novel formulations of composites, hybrid systems, structural performance, structural health monitoring techniques for composites, life-cycle assessment, and the role of composites in resilient and sustainable infrastructure. The aim of this collection is to provide a platform for researchers and practitioners to share their findings, driving innovation and expanding the possibilities of composite materials in civil engineering.

This Collection supports and amplifies research related to: SDG 9: Industry, Innovation, and Infrastructure

Keywords: Cementitious composites, Fiber-reinforced polymers, Fiber-reinforced concrete, Hybrid composites, Structural durability, Resilient infrastructure, Sustainable materials, Structural health monitoring, Life-cycle assessment

Publishing Model: Open Access

Deadline: Feb 28, 2026

Please sign in or register for FREE

If you are a registered user on Research Communities by Springer Nature, please sign in