Deep Learning for Refractory Materials

The function of refractory materials is to withstand high temperatures required in e.g. furnaces, kilns, incinerators, power plants, without contaminating other materials. Further, heat in the area where it is needed should be conserved. Oxides of example like aluminium (Al), silicon (Si) and magnesium (Mg) are the most important materials used in the manufacturing of refractories.

Refractories often face corrosive wear due to diffusion in liquid slags at high temperatures. Therefore, accurate dissolution experiments and efficient quantification approaches are essential for designing refractory products with more wear resistant and long service life.

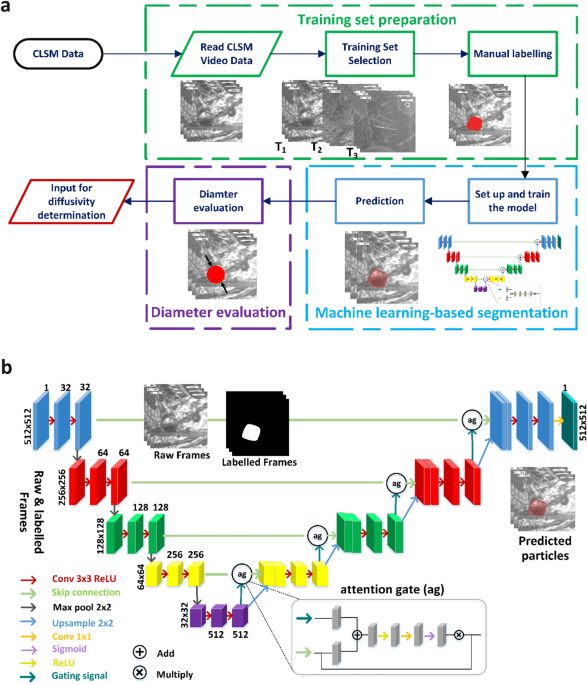

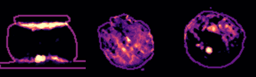

Here, high temperature-confocal laser scanning microscopy (HT-CLSM) displays a highly suitable in-situ method to study the underlying dissolution kinetics in the slag over time. However, a major drawback concerns the efficient and accurate processing of the collected image data.

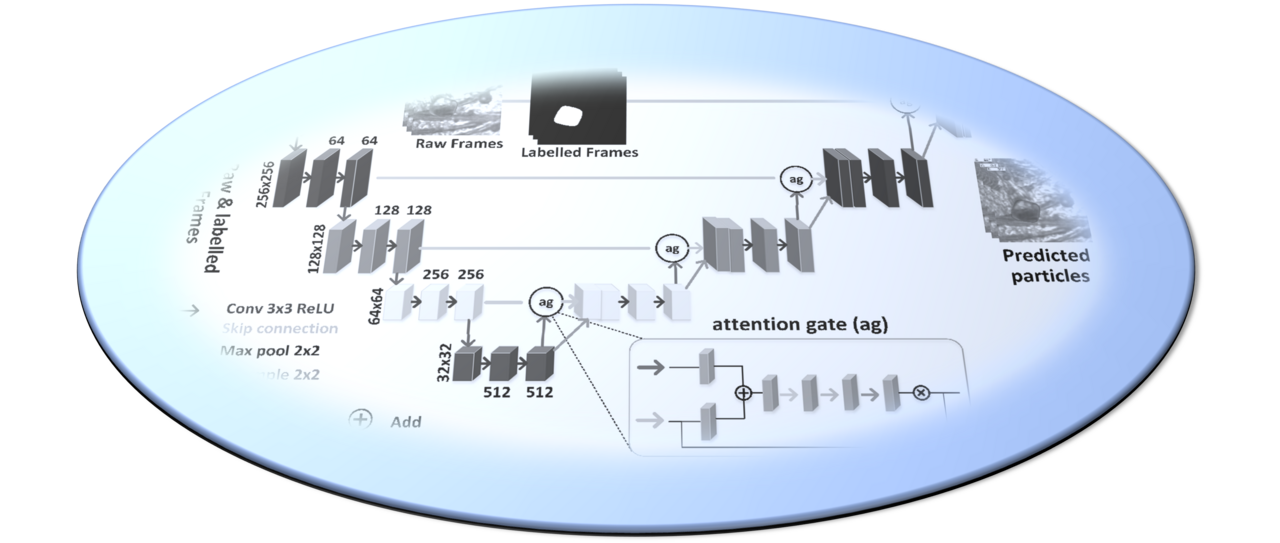

Deep learning provides intriguing possibilities in the field of image recognition and processing. U-Net architectures have become a widely adopted and influential models. The modular nature of U-Net allows for easy customization and adaptability, making it a versatile solution for a wide range of image segmentation problems. A conventional U-Net architecture usually consists of an encoder and decoder, connected by skip connections. Here, the encoder extracts hierarchical features, while the decoder combines them to create the final segmentation.

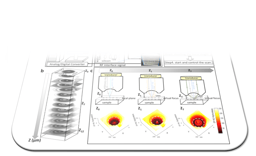

In the published work we developed a deep learning-driven workflow to evaluate in an automated manner the dissolving of MgO particles in the slag over time. The image data was genereated by in-situ high temperature-confocal laser scanning microscopy (HT-CLSM). For the analysis of the image data at different time steps, an attention encoder-decoder convolutional neural network (atU-Net) architecture was developed and applied.

The attention gate within the U-Net architecture makes it possible to localize the MgO particles in the slag while boosting overall prediction performance by decreasing miss-segmentation.

The work represents an important step towards accelerated material development for refractory materials and triggers possibilities in context to enhanced energy efficiency for industrial processes.

Further, we argue that the application of the developed atU-Net is not restricted to the evaluation of particle dissolving rates; rather, it offers an approach for accurate and efficient particle tracking and identification in various data types such as scanning electron microscopy (SEM), micro- X-ray computed tomography (µ-XCT), etc., as well as across other domains.

Great work by Fereshteh who is a post doc in the group Brunner “Material and Damage Analytics” at MCL with support by the master student Florian.

The work was done in collaboration with the Montanuiversität Leoben, Chair of Ceramics and funded by the COMET program within the K2 Center "Integrated Computational Material, Process and product Engineering (IC-MPPE), Proj. No. 886385. Special thank´s to Burhanuddin Burhanuddin, Volkamr Kircher, Sandra Vollmann and Dietmar Gruber from the Montanuniversität Leoben for providing the experimental data.

The work is published in: Deep learning revealed statistics of the MgO particles dissolution rate in a CaO–Al2O3–SiO2–MgO slag | Scientific Reports (nature.com)

Follow the Topic

-

Scientific Reports

An open access journal publishing original research from across all areas of the natural sciences, psychology, medicine and engineering.

Related Collections

With Collections, you can get published faster and increase your visibility.

Reproductive Health

Publishing Model: Hybrid

Deadline: Mar 30, 2026

Obesity

Publishing Model: Hybrid

Deadline: Apr 24, 2026

Please sign in or register for FREE

If you are a registered user on Research Communities by Springer Nature, please sign in