Engineered yeast good at straw-sugar conversion

Published in Bioengineering & Biotechnology

Novozymes, the world leader in biofuel enzymes, has introduced the first commercially viable enzymes for hydrolysis of pretreated plant cell walls to lignocellulose hydrolysates, which contain glucose, xylose, other carbohydrates, and diverse small molecules. The conversion of xylose into ethanol from lignocellulosic hydrolysates containing microbial inhibitors was then a major bottleneck in lignocellulosic biofuel production.

While waiting for the delayed flights in the airport lounge, Dr. Wenping Wu from Novonesis (combination of the legacy companies Novozymes and Chr. Hansen) managed to persuade me to develop a robust xylose yeast against dilute acid steam-exploded corn stover enzymatic hydrolysates for local cellulosic ethanol production.

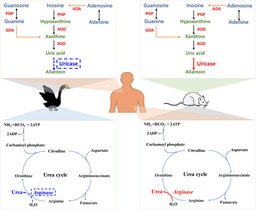

Started up with a yeast strain widely used for ethanol production from corn in China, my lab and the Shanghai R&D Center of Industrial Biotechnology under my responsibility identified sodium salts as the primary yeast inhibitors in the corn stover hydrolysates, and evolved an engineered yeast overexpressing xylose catabolism genes in xylose/glucose-mixed medium containing sodium salts. The full-evolved strain can efficiently convert xylose in the hydrolysates to ethanol. It not only met the success criteria of lignocellulosic ethanol production in China, but also outperformed all other strains that Novozymes had received for benchmark or received performance data. It has been used for the conversion of corn-stover in the US and bagasse in Brazil, reaching tens of thousands of tons cellulosic ethanol per year.

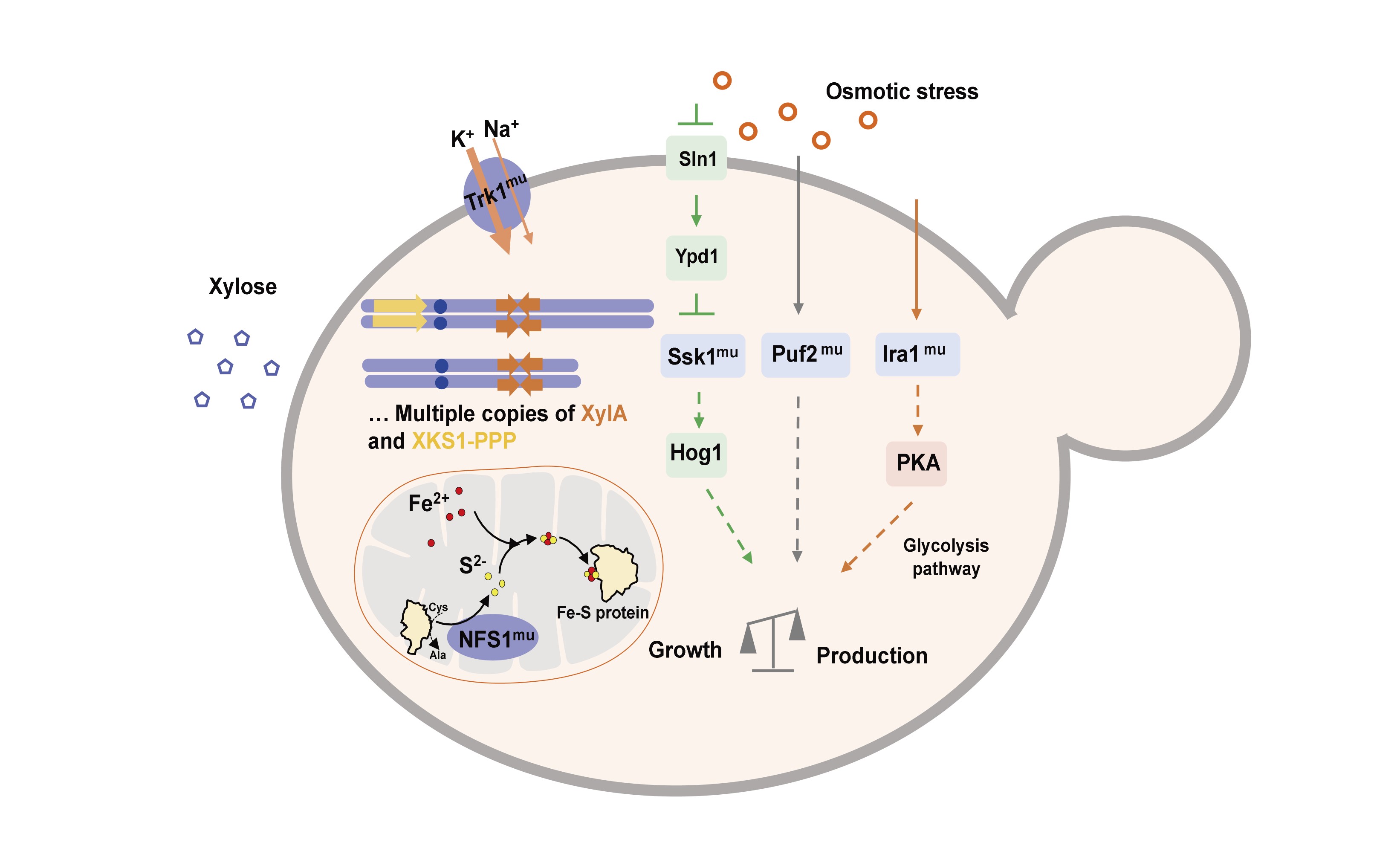

In the hundreds of genomic alterations of evolved strains, we identified and reintroduced seven genomic alterations back into a clean parental background, which resulted in total reconstruction of the phenotype. Meanwhile, the mechanisms of every effective genomic alteration in this minimalist modification set were investigated. This work should be a technological milestone for nearly 20 years of xylose yeast research and development. Our evolved/reverse-engineered yeasts enable industrial-scale lignocellulosic ethanol production and are believed to be able to expand the feedstocks of cell factories producing chemicals beyond ethanol to biomass by providing a suitable chassis as well as genetic and biochemical design rationales.

Robert Osborne, Novonesis’ Director of BioRefining R&D North America, stated, “Novonesis recognizes the best in class performance for biomass conversion with yeast developed by the CAS Center for Excellence in Molecular Plant Sciences. The current technology and its continued development will support the advancement and development of 2G biorefineries across the globe.”

Professor Yingjin Yuan from Tianjin University, an academician of the Chinese Academy of Sciences, is an expert in the synthetic biology of Saccharomyces cerevisiae. He commented: "The industrial demonstration of cellulosic ethanol has been included in the Chinese 14th Five-Year Plan for Bioeconomy Development. There are still many challenges in its large-scale production, including that pretreatment processes for different biomass raw materials are required. This work by Professor Sheng Yang not only reveals the inhibition mechanism of the dilute-acid steam explosion pretreatment process of corn stover on yeast, but also provides a research idea for systematically identifying inhibitory components in complex raw materials and how to overcome them, which has important enlightenment and reference significance for the field of biomass conversion."

Professor Jens Nielsen, a member of 12 academies, including NAS, NAE, NAM, Chinese Academy of Engineering, and Royal Swedish Academy of Science, is an expert in the system biology of Saccharomyces cerevisiae. He commented, “In this impressive study Sheng et al demonstrated how they could develop an industrial yeast strain that efficiently can convert pentoses to ethanol. Through a combination of metabolic engineering and adaptive laboratory evolution, they developed a strain that is sufficiently robust to tolerate the harsh industrial conditions yeast has to endure during industrial ethanol production. The work is a fantastic demonstration of how different technologies could be combined to obtain new mechanistic insight into yeast physiology and at the same time generate an industrial strain that immediately could find applications in a very important area, namely sustainable production of biofuels.”

Follow the Topic

-

Nature Chemical Biology

An international monthly journal that provides a high-visibility forum for the chemical biology community, combining the scientific ideas and approaches of chemistry, biology and allied disciplines to understand and manipulate biological systems with molecular precision.

Please sign in or register for FREE

If you are a registered user on Research Communities by Springer Nature, please sign in