Fascinating room temperature self-healing of diamond

Published in Materials

As a typical type of super hard Covalent bond materials, diamond is known as the hardest material in the world. However, its application is still dramatically limited by its intrinsic brittleness. In 2020, Prof. Yonghai Yue and Prof. Lin Guo in our group at Beihang University, and the group of Prof. Yongjun Tian at Yanshan University developed a new kind of hierarchically structured nanotwinned diamond composite (ntDC), the toughness of which was dramatically improved without sacrificing its hardness (Nature 2020, 582, 370-374). In that work, the toughness of ntDC was tested to be as high as ~27 MPa·m0.5, over 5 times higher than the toughness of diamond single crystal (DSC). However, diamond’s inherent fragility more often than not presents catastrophic failure, which poses a major threat to the reliability and service life of diamond-based components. Interestingly, we observed a fascinating self-healing phenomenon in ntDC when we conducted the bending test of an end-fixed single-edge notched ntDC beam to determine the toughness of the ntDC. The crack underwent a self-healing process after the removal of the indenter due to the switched compressed stress upon unloading near the crack tip region. Since then, we had been pondering if diamonds could trigger self-healing once cracks appear just as living organisms. If it comes true, it will definitely be of revolutionary significance to improving the service life and reliability of diamond-based materials and devices. Theoretically speaking, this phenomenon we observed is rather surprising as C-C nonpolar covalent bonds in diamond is the strongest, which is theoretically not possible to have sufficient mobility at room temperature (RT) to heal itself. Also, what puzzles us most is whether it will heal itself like an injured organism? Therefore, Prof. Yonghai Yue, Prof. Anmin Nie, Prof. Yongjun Tian and Prof. Lin Guo attempted to explore and confirm this interesting conjecture using in situ tensile tests in scanning electron microscopy (SEM) and transmission electron microscopy (TEM). Dr. Keliang Qiu, Dr. Jingpeng Hou, Dr. Xiang Li, and Master student Jing Wang in our research group began to study this inconceivable phenomenon quantitatively. Dr. Shuai Chen, Dr. Yufei Gao and Dr. Tianye Jin at Yanshan University were responsible for preparing ntDC samples.

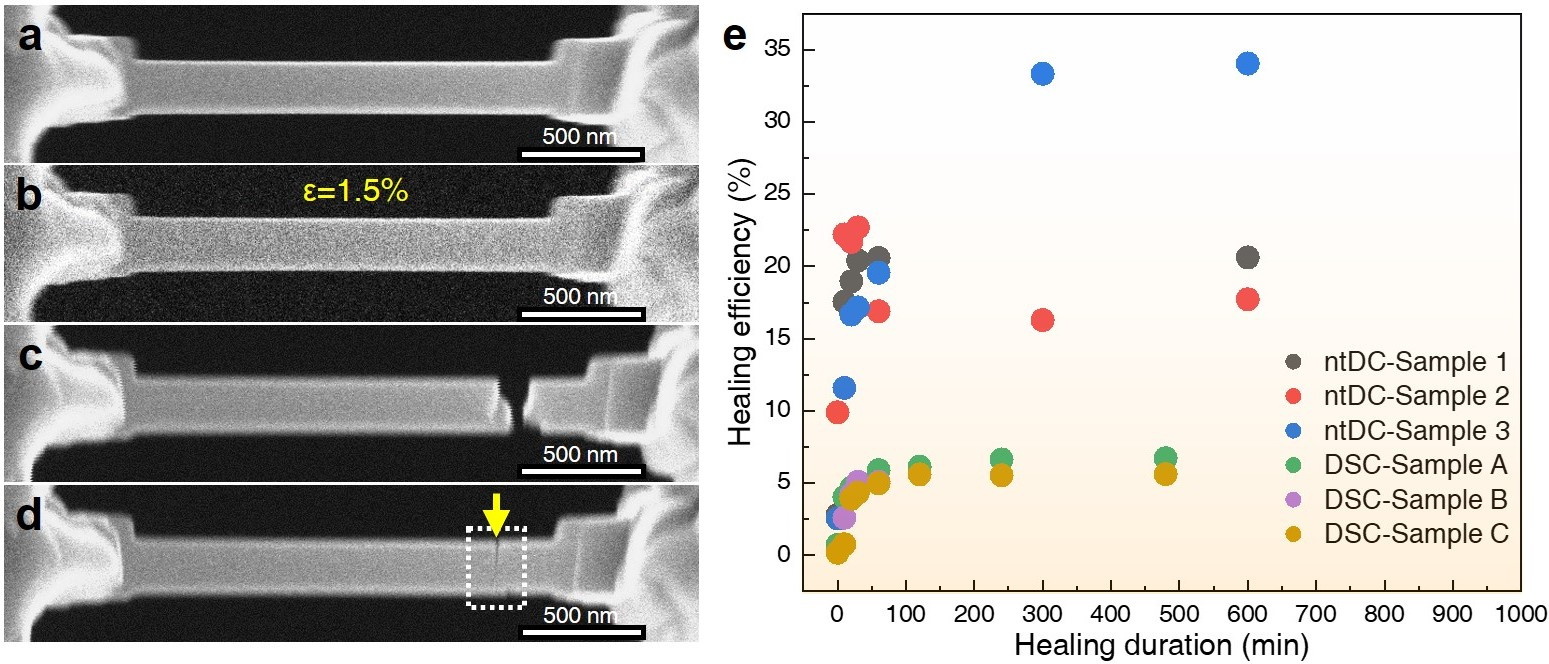

Different from the bending test employing an end-fixed single-edge notched ntDC beam, we redesigned a uniaxial multi-cycle tensile fracture test to quantitively study the self-healing behavior of ntDC, and we successfully replicated this extraordinary crack self-healing at RT in fully fractured ntDC, without relying on external interventions such as compressive stress. It defies intuitional expectations, as carbon atoms in diamond, bonded by strong C-C covalent bonds, lack the necessary mobility at RT to facilitate self-healing. Fig. 1a-c display SEM images at different tensile stages during the first tensile fracture test. Then, the applied tensile force was released, allowing the two fractured surfaces to come into contact without any compressive force (Fig. 1d). Multiple loading-unloading cycles were then performed on the ntDC-NB, with different incremental healing durations to investigate the influence of healing duration on healing efficiency (Fig. 1e). In stark contrast to the inadequate recovery about 6.7% observed in DSC, ntDC exhibited an impressive recovery of approximately 34% in tensile strength, and such self-healing behavior could still work on the ntDC-NB even with a size of micrometer scale. Our results establish a clear relationship between self-healing efficiency and healing duration after multiple fractures, with ntDC exhibiting an impressive recovery in tensile strength.

Fig. 1 | Multi-cycle tensile fracture test on the ntDC-NB and DSC-NB with a width of 220 nm. a to d, SEM images at different stages during the initial tensile fracture test. e, The healing efficiency vs. healing duration for three ntDC-NB samples and three DSC-NB samples with a width of ca. 200 nm, which demonstrate an outstanding healing efficiency (up to ca. 34% for ntDC Sample 3).

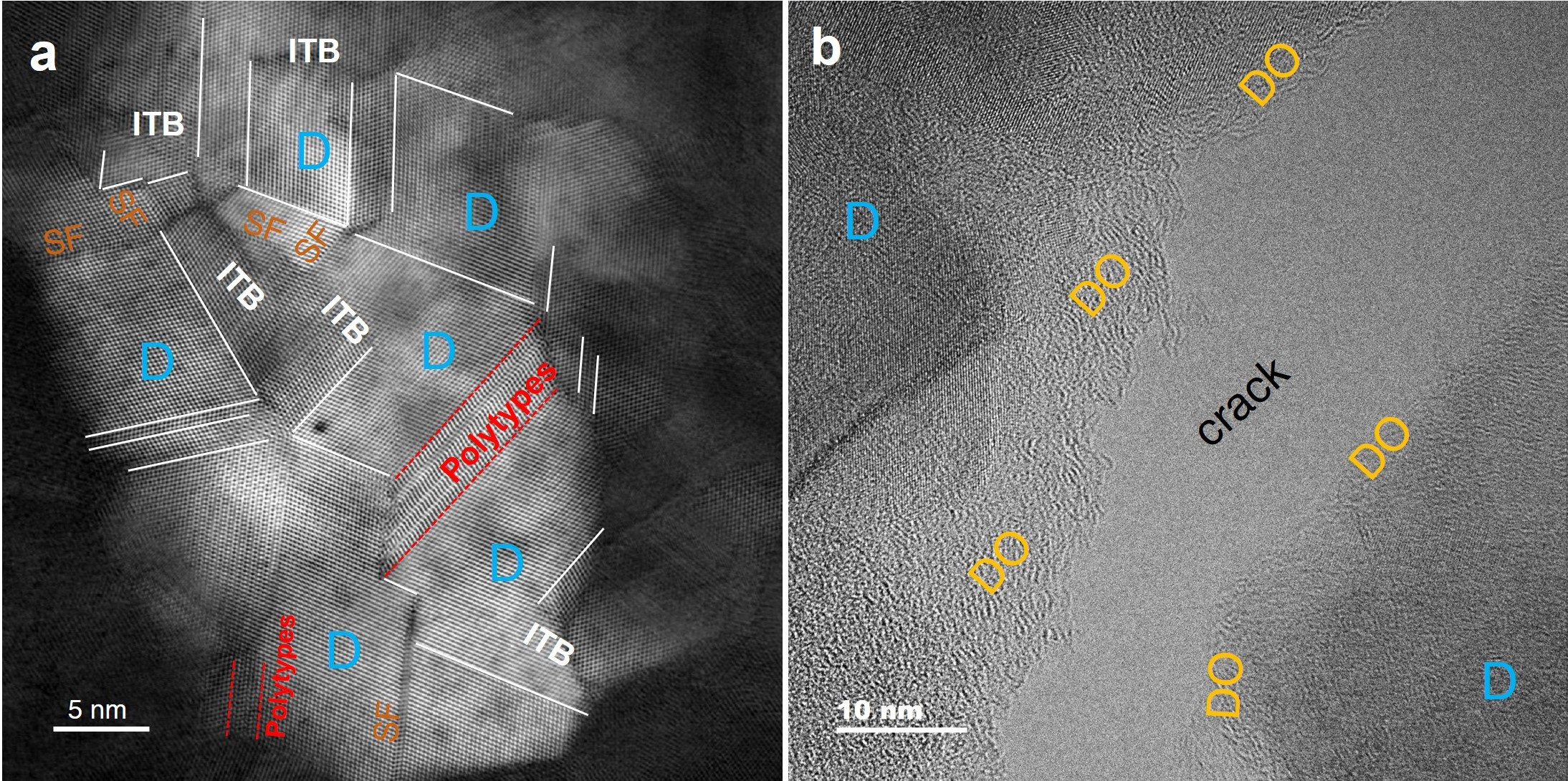

To investigate the RT self-healing process and further elucidate the mechanism for this phenomenon, Prof. Yonghai Yue at Beihang University and his PhD students Keliang Qiu, Jingpeng Hou, Xiang Li, and Prof. Anmin Nie at Yanshan University conducted in situ multi-cycle tensile fracture tests on ntDC and DSC in transmission electron microscopy (TEM). The typical microstructure of ntDC is featured by the interlocked nanograins containing numerous nanotwins and laminar diamond polytypes (Fig. 2a). Fig. 2b shows an enlarged TEM image taken after single tensile test. Amorphization of ntDC occurred in front of the crack tip, and the amorphous carbon region was torn into two parts, forming the diamond osteoblast (DO) phases on the fractured surfaces.

Fig. 2 | Microstructure of ntDC and TEM observation of the formation of DO phases at the fractured surfaces. a, A high-magnification ADF-STEM image of a grain containing nanotwins and diamond polytype domains. Σ3{111} TBs (white line), Σ3{112} incoherent TBs (ITB), stacking faults (SF) and diamond polytype domains (red dashed line) are marked. b, TEM image taken after the fracture. D and DO mean diamond and diamond osteoblast, respectively.

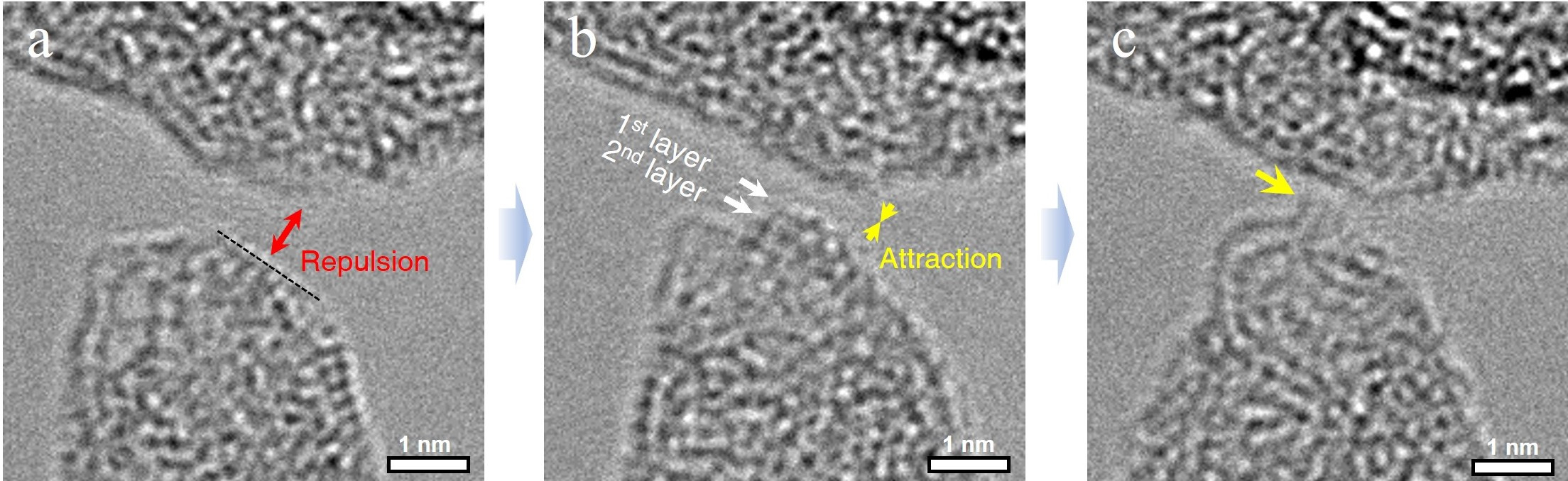

Figure 3 provides an overview of the dynamic healing process between two disconnected fracture surfaces with DO protrusions. As the two fractured surfaces approached each other, the initially convex DO protrusions transformed into an atomically flat shape at a distance of about 7 Å (Fig. 3a, see the straight line on top of the free end), suggesting the presence of a repulsive force. With further reduced distance, a small bi-layer synapse was pulled towards the opposite DO (Fig. 3b), signifying a transition from a repulsive force to an attractive one. Continued reduction in the distance led to the formation of carbon linkages between the opposing DOs (see the yellow arrows in Fig. 3c), indicating the creation of additional bonds through sp3-hybridaztion.

Fig. 3 | Dynamic healing process of two fractured surfaces with DO protrusions. a to b, The atomic interaction transition from repulsion to attraction, which shows a small bi-layer synapse pulled towards the opposite DO in b. c, The formation of carbon linkages as two fracture surfaces approach further.

In order to theoretically reveal the self-healing mechanism, Prof. Limin Liu, Dr. Qi Hu at School of Physics, Beihang University and Prof. Zhenyu Yang at School of Aeronautics Sciences and Engineering, Beihang University performed first principles/molecular dynamics simulation calculation. When preparing the manuscript, Prof. Bo Xu at Yanshan University, Prof. Yanbin Wang at University of Chicago, and Dr. Yanhong Li at Beihang University helped us to polish the manuscript and improve the quality of the manuscript. Here, we truly appreciate their contributions.

It is really incredible to see self-healing of diamond at RT, especially because they are typical covalent bonding materials. However, the self-healing behavior in ntDC observed in this work predicted the potential of nanostructured microstructures to repair cracks in inherently brittle materials. This discovery provides a new idea for the design and development of brittle ceramic materials with high durability and fracture resistance. Furthermore, it is of great significance to the development of RT wafer direct bonding technology for semiconductor materials. In addition, it provides a new method to improve the safety and reliability of the application of brittle covalent materials.

In the future, we will mainly focus on exploring the self-healing behavior of covalent bonded materials under compressive stress, revealing the direct bonding technology and mechanism of materials at room temperature and high pressure.

Follow the Topic

-

Nature Materials

A monthly multi-disciplinary journal that brings together cutting-edge research across the entire spectrum of materials science and engineering, including applied and fundamental aspects of the synthesis/processing, structure/composition, properties and performance of materials.

Please sign in or register for FREE

If you are a registered user on Research Communities by Springer Nature, please sign in