Finding a way to aerogels with bendability and glasslike transparency

Published in Materials

What drove us to this research?

With the growing demand for efficient energy conservation, high-performance thermal insulators are increasingly needed. Aerogels, especially transparent ones like silica aerogels, are unique materials due to the combination of transparency and low thermal conductivity, which makes aerogels ideal for thermal insulating windows, for example. Although the aerogel was first discovered about 90 years ago1, its mechanical friability is still problematic, which makes the industrial applications of aerogels challenging. It is well known that the mechanical properties of low-density materials are determined by both the solid constituents and the cellular structure2,3, and many efforts have been devoted to improve mechanical properties of aerogels by varying their solid components, such as silica reinforced with organic polymers4, utilizing fiber materials5–7, etc. These approaches, however, can hardly avoid changes in other characteristics of the resulting aerogels, such as the pore structure and density, which makes it unclear what their mechanical properties are derived from. Therefore, we started this research with the idea that the mechanical properties of transparent aerogels with fine pores should be changed by changing only the porous architecture. The purpose of this research was to improve the mechanical flexibility, especially bendability, of highly transparent aerogels, and to better understand the relationship between the nanostructure of the aerogel and bulk mechanical properties.

What are the keys to bendable and transparent aerogels?

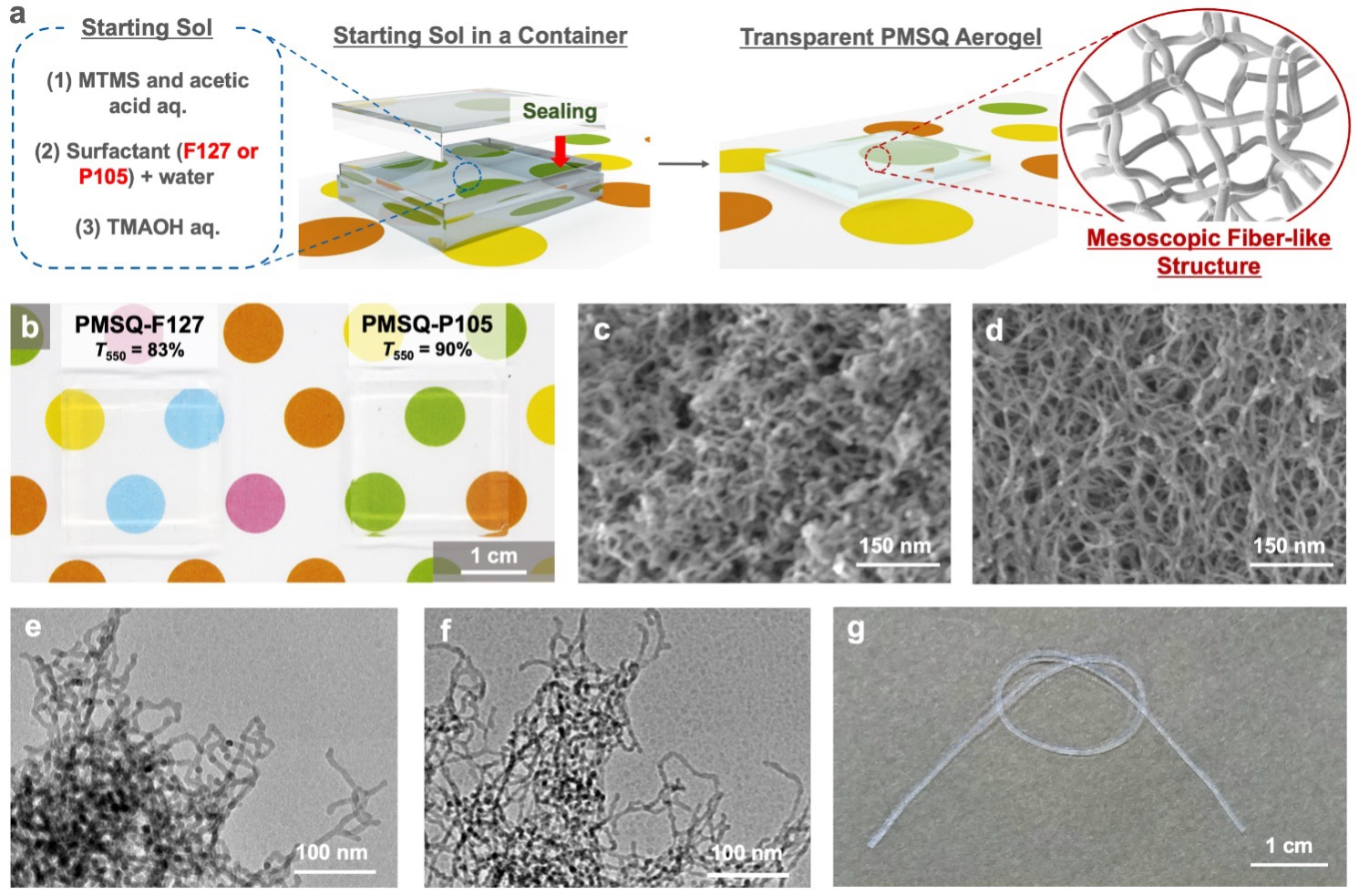

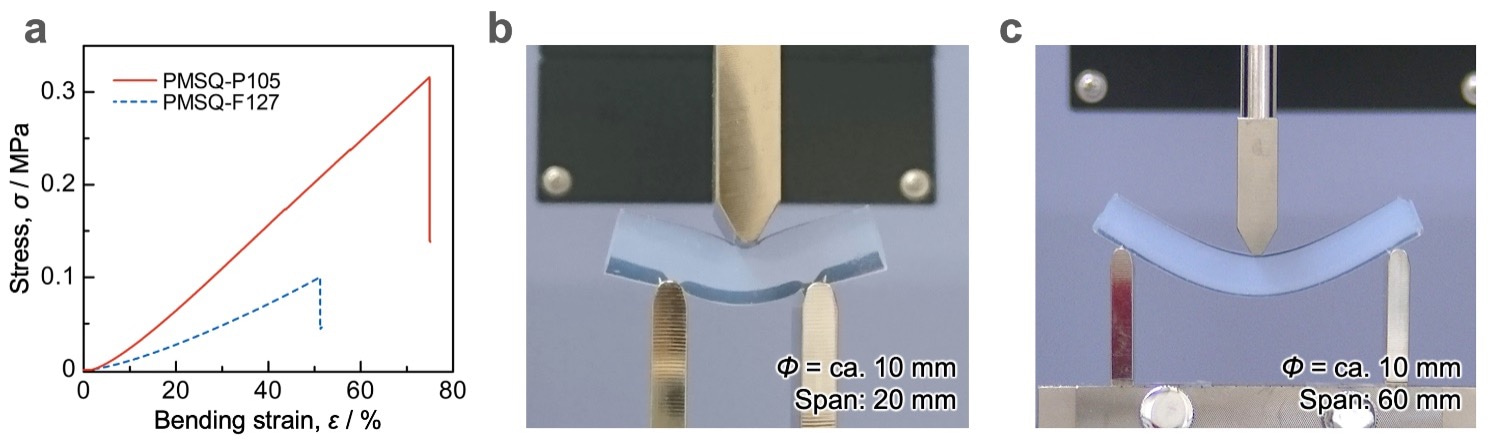

To construct a nanostructure suitable for bending flexibility of aerogels, we focused on fiber-based geometry. Some studies have reported that the aerogels made of fiber materials exhibit high bending flexibility5,8. Fortunately, in our previous study, we have obtained poly(methylsilsesquioxane) (PMSQ) aerogels with an unusual porous architecture (i.e., one-dimensionally long skeletons)9. Therefore, we came up with an idea that further reduction of the scale of this unique nanostructure would result in highly transparent aerogels with improved bendability. The key to this research was the combination of poly(ethylene oxide)-b-poly(propylene oxide)-b-poly(ethylene oxide) (PEO-b-PPO-b-PEO) type surfactants (known as Pluronic) and an organic strong base, tetramethylammonium hydroxide (TMAOH), as the structure determining agent and polycondensation catalyst, respectively. The Pluronic helps to form nanostructures with one-dimensionally long skeletons (i.e., fiber-like structure), while TMAOH helps to form finer pore structures by effectively suppressing phase separation. By optimizing the starting composition, we have successfully prepared highly transparent PMSQ aerogels with fine fiber-like structures (Fig. 1). The resulting aerogels were clearly mechanically flexible, and when their bending properties were evaluated by three-point bending tests, we found that they have significantly higher bendability than other reported aerogels (Fig. 2). To the best of our knowledge, firstly, the aerogels that are as highly transparent as the PMSQ aerogels obtained in this study are only friable silica aerogels. In addition, all the aerogels that have been reported to have excellent bendability are translucent or opaque, and most of them are thin shapes; no aerogels that have high bendability in thick shapes are as bendable as the PMSQ aerogels obtained in this study. In other words, there are no aerogels comparable to our ones in terms of bending flexibility alone.

Fig. 1. Macro-/mesoscopic physical features of the flexible and transparent PMSQ aerogels prepared with two types of surfactants. (a) The starting compositions were optimized to prepare highly transparent PMSQ aerogels with the mesoscale fibrous structure. (b) Appearance of the PMSQ aerogels prepared with the different surfactant, F127 and P105. (c,d) FE-SEM images of the samples PMSQ-F127 and PMSQ-P105, respectively. (e,f) TEM images of the samples PMSQ-F127 and PMSQ-P105, respectively. (g) A photograph of the string-shaped sample of PMSQ- F127, demonstrating high flexibility like a silicone tube.

Fig. 2. Mechanical properties for bending deformation of the flexible and transparent PMSQ aerogels prepared in different conditions. (a) Stress–strain curves obtained from three-point bending of the PMSQ aerogel samples with 20mm span. (b,c) Photographs showing the bendability of (b) PMSQ-P105 (span: 20mm) and (c) PMSQ-F127 (span: 60mm). Both photos show the aerogels just before the failure.

What is the origin of the superior bending properties?

We prepared and compared several PMSQ aerogels with similar density and transparency (i.e., porous structure size) but different skeletal geometries: fiber-like structures and particle aggregation-like structures. Chemical analysis of these aerogels by nuclear magnetic resonance (NMR) and thermogravimetry-differential thermal analysis (TG-DTA) show that there is no clear correlation between the bending properties and the molecular-level structures. To clarify the differences in the nanostructures, we calculated several size parameters from the field-emission scanning electron microscopy (FE-SEM) and transmission electron microscopy (TEM) images of these PMSQ aerogels. The pore skeletons can be classified into (i) 1D skeletons and (ii) their connections (nodes). The image analysis shows that the average lengths of the 1D skeletons differ significantly: fiber-like structures have long 1D skeletons (high aspect ratio) and particle aggregation-like structures have short ones (low aspect ratio). These results suggest that the characteristic fiber-like structures would contribute to the significant increase in bending flexibility. We have also conducted a systematic survey of Pluronic types used in PMSQ aerogel preparation; we have constructed various sizes of nanoporous structures. The results obtained in this survey support the above idea. Furthermore, we have found that highly transparent PMSQ aerogels comparable to window glass can be produced with optimized compositions. This study shows that, to obtain highly transparent aerogels with high bending flexibility, it would be important to use Pluronic with a high molecular weight and a moderate hydrophilic-lipophilic balance (HLB) value (somewhere between 12–18 for PMSQ).

Outlook

This study demonstrates highly transparent aerogels with outstanding bending flexibility, and shows that even for aerogels with fine pores that exhibit high transparency, the bulk mechanical properties can be changed significantly by changing the porous architectures. We believe that this study is beneficial toward the industrial use of aerogels, and also will promote further understanding of the relationship between mechanical properties and cellular architecture in porous materials.

References

- Kistler, S. S. Coherent Expanded Aerogels and Jellies. Nature 127, 741–741 (1931).

- Gibson, L. J. & Ashby, M. F. Cellular solids: Structure and properties. (Cambridge University Press, 1997).

- Schaedler, T. A. et al. Ultralight metallic microlattices. Science 334, 962–965 (2011).

- Leventis, N. Three-Dimensional Core-Shell Superstructures: Mechanically Strong Aerogels. Acc. Chem. Res. 40, 874–884 (2007).

- Kobayashi, Y., Saito, T. & Isogai, A. Aerogels with 3D Ordered Nanofiber Skeletons of Liquid‐Crystalline Nanocellulose Derivatives as Tough and Transparent Insulators. Angew. Chem. Int. Ed. 53, 10394–10397 (2014).

- Cai, J. et al. Cellulose–Silica Nanocomposite Aerogels by In Situ Formation of Silica in Cellulose Gel. Angew. Chem. Int. Ed.51, 2076–2079 (2012).

- Shafi, S., Navik, R., Ding, X. & Zhao, Y. Improved heat insulation and mechanical properties of silica aerogel/glass fiber composite by impregnating silica gel. J. Non. Cryst. Solids 503–504, 78–83 (2019).

- Takeshita, S. & Yoda, S. Chitosan Aerogels: Transparent, Flexible Thermal Insulators. Chem. Mater. 27, 7569–7572 (2015).

- Kanamori, K., Aizawa, M., Nakanishi, K. & Hanada, T. New transparent methylsilsesquioxane aerogels and xerogels with improved mechanical properties. Adv. Mater. 19, 1589–1593 (2007).

Text by Ryota Ueoka and Kazuyoshi Kanamori

Follow the Topic

-

Nature Communications

An open access, multidisciplinary journal dedicated to publishing high-quality research in all areas of the biological, health, physical, chemical and Earth sciences.

Related Collections

With Collections, you can get published faster and increase your visibility.

Women's Health

Publishing Model: Hybrid

Deadline: Ongoing

Advances in neurodegenerative diseases

Publishing Model: Hybrid

Deadline: Mar 24, 2026

Please sign in or register for FREE

If you are a registered user on Research Communities by Springer Nature, please sign in