Fractured Art - Printing with Cracks

Published in Electrical & Electronic Engineering

What is fracture? Generally speaking, it happens when things break. People break down; When they can't take anymore, they simply break-down, and often with disastrous consequences. For material scientists, fracture occurs when a material is unable to cope with the immense amounts of stress being applied to it. We can stress a material in many different ways: stretching, bending, heating, and even chemically. Often under this stress the material will fail and it will either deform or, if the material cannot respond fast enough, it will fail catastrophically by cracking. Such breakdown is almost always undesired and much research effort is put towards making materials resistant to crack growth and failure propagation.

In our recent research we have instead embraced the formation of cracks to make microstructures that have large scale effects, such as color. Our approach uses the interference of light (standing waves) to selectively crosslink a polymer film. In doing so we imprint regions in the film that will crack when exposed to a solvent, resulting in a layered nanoporous film. Not only is the film nanoporous, but light interacts with the periodic layers to strongly reflect specific wavelengths of light. We call this phenomenon Organized Microfibrillation and the video below gives a brief overview of what it is all about.

We first encountered this phenomenon in polystyrene type materials that were irradiated with ultra-violet light. However, over the course of several years, we were able to demonstrate that this effect can be generalized and applied to variety of glassy polymers with a wide range of light sources with different colors (wavelengths). The different colored light sources allow us to alter the final color of our material. Showing these two generalizations was by far the most challenging part of our research and require us to step back a number of times to revise how we understood our own process.

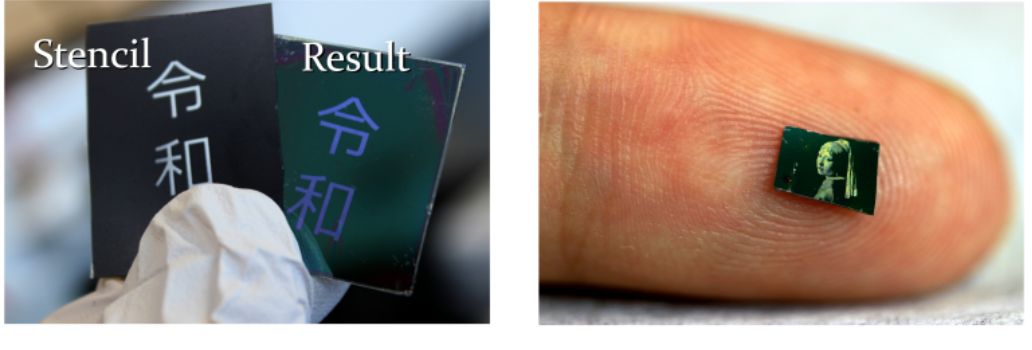

The best part of doing this research was making pictures with our process. Not everyone can spend their day making art with science. We tried a lot of techniques for making images, from the very simple to the quite advanced. A very easy method form making images is to simply print the image onto common OHP paper, and use it as a stencil during irradiation, this can be seen below with a printing of the Kanji for Reiwa, the new Japenese era. A more advanced method was used to print at the micron scale. We spent a lot of time every week in a clean room printing image after image with a microLED, refining our technique. Examples of both of these techniques are shown in the image below.

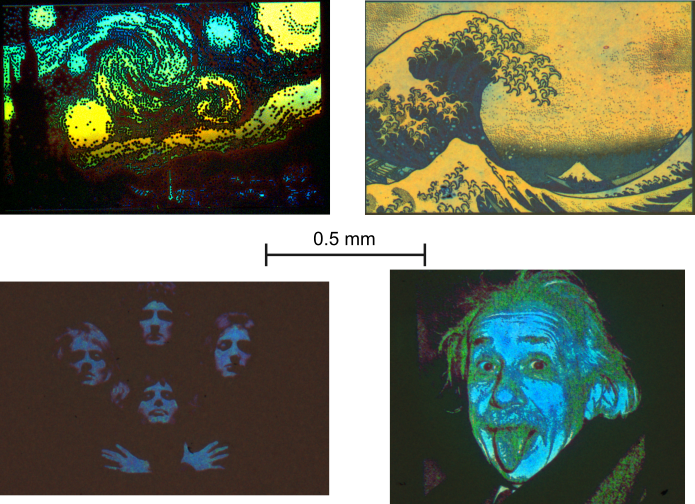

With this method we were able to make printings of iconic images. Everyone in our group has different tastes in art, so below is a variety of our favorites. (Starry Night, The Great Wave off Kanagawa, Queen, Einstein). We are grateful to the staff of the Kyoto University NanoHub for providing this equipment and their regular assistance.

While printing pleasing pictures is one possible application of organized microfibrillation, behind the scenes we have also been exploring other interesting uses of our method. With such small scale polymer printing, we think there are useful applications for organized microfibrillation in security and anti-counterfeit features. The nanoporous properties of the structure also suggests the possibility of using the method to facilitate flow of liquids at the micron scale. The optical and potential flow aspects of our microstructure also seem like an exciting synergy that could lead to things like small scale, flexible sensors. Of course at the end of the day, maybe people just want tiny pictures!

We carried out this research as part of the Pureosity group at iCeMS, Kyoto University. iCeMS is a combined material science and cell biology research institute. It can seem like a difficult hurdle to establish a large international research group in Japan, but iCeMS was developed to encourage international research, by providing high quality facilities and assistance to help us get up and running effectively. iCeMS has been able to nuture a very friendly and helpful working environment for its many international researchers and students. I think our sub-group within Pureosity shown below demonstrates this well: we have two members from China, one from Ireland, one from Japan, and one from Britain.

We in the Pureosity group (www.pureosity.org) hope to see the other creative ideas that the rest of the scientific community can come up with for technique of Organized Microfibrillation.

Follow the Topic

-

Nature

A weekly international journal publishing the finest peer-reviewed research in all fields of science and technology on the basis of its originality, importance, interdisciplinary interest, timeliness, accessibility, elegance and surprising conclusions.

Please sign in or register for FREE

If you are a registered user on Research Communities by Springer Nature, please sign in