From Friction to Freedom: How Superlubricity Could Redefine Sustainable Technology

Published in Materials

The Journey Toward Superlubricity

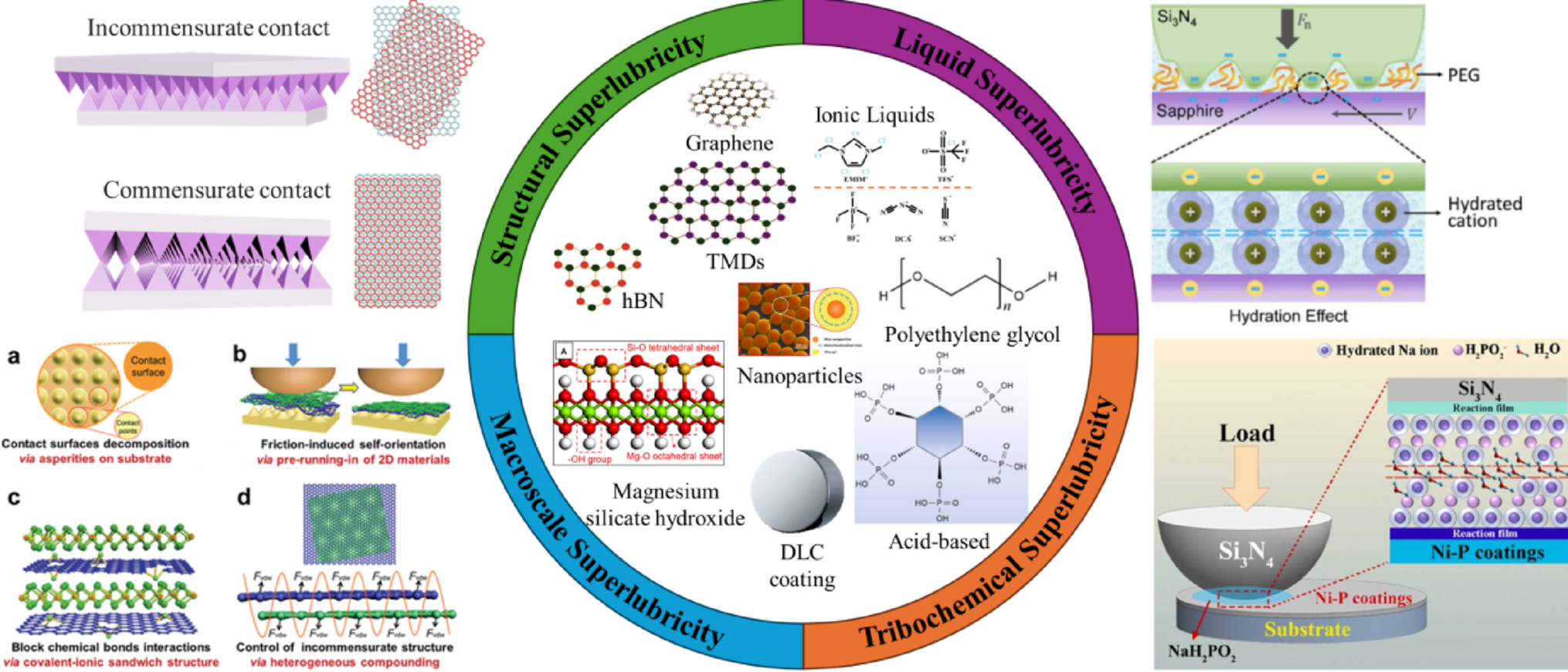

Superlubricity describes a near-frictionless state where the coefficient of friction drops below 0.01. What began as atomic-scale observations in materials like graphite and molybdenum disulfide has evolved into a multidisciplinary field that brings together physics, materials science, chemistry, and mechanical engineering.

Our review traces this evolution, from the discovery of incommensurate lattice alignment to the development of adaptive carbon coatings, two-dimensional heterostructures, and liquid lubricants. Each breakthrough offers new insight into how friction can be controlled by manipulating surface energy, chemical bonding, and structural alignment.

We emphasize the shift from ideal atomic interfaces to realistic engineering systems, where the goal is not perfection but adaptability. The future of superlubricity lies in intelligent materials that can self-organize, self-heal, and maintain stable low-friction behavior under real operating conditions.

Why Superlubricity Matters for Sustainability

Reducing frictional losses even by 40 percent could cut global CO2 emissions by more than one billion tons every year. In this sense, superlubricity is not just a scientific phenomenon but a key to sustainable technology.

By integrating low-shear coatings and environmentally friendly lubricants, engineers can create machines that last longer, use less energy, and generate less waste. The same principles apply to nanoscale actuators, robotics, renewable energy devices, and medical implants.

Looking Ahead

Although progress has been remarkable, major challenges remain. Achieving stable and scalable superlubricity under varying humidity, temperature, and load requires deeper understanding of tribochemical reactions and interfacial dynamics.

Future studies will focus on real-time diagnostics, multiscale modeling, and the design of adaptive lubricants that can function across different environments.

The journey from friction to freedom is still unfolding, but the path ahead is now clearer and smoother than ever before.

Author Introduction

This review was led by Dr. Yuzhen Liu, Research Professor at the Department of Mechanical Engineering, Yonsei University, Republic of Korea, specializing in tribology and surface engineering.

Prof. Dae-Eun Kim is the Director of the Tribology Laboratory at Yonsei University, focusing on nanoscale friction, wear, and lubrication mechanisms.

Follow the Topic

-

International Journal of Precision Engineering and Manufacturing-Green Technology

This journal centers on the 'green' aspects of precision engineering and manufacturing.

Please sign in or register for FREE

If you are a registered user on Research Communities by Springer Nature, please sign in