High performance crystalline nanocellulose using an ancestral endoglucanase

Published in Electrical & Electronic Engineering

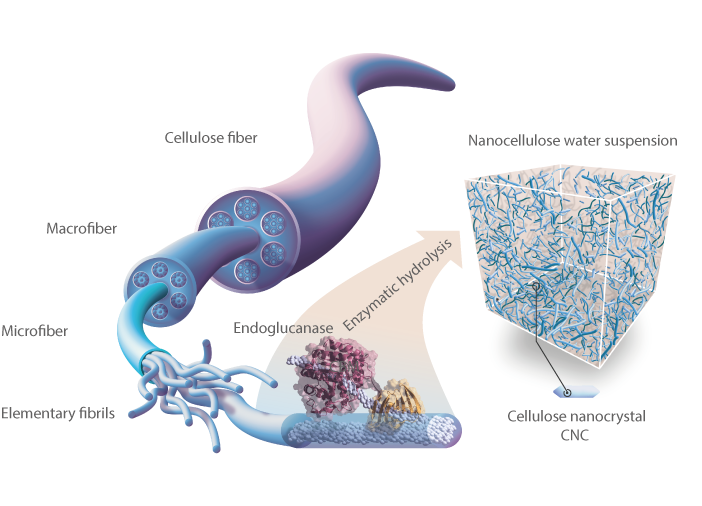

This work just published in Communications materials was the main project of my Ph.D. thesis. The idea came up when we asked ourselves if we could produce nanocellulose with a single enzymatic method. Nanocellulose is a natural polymeric material that has attracted the attention of the research community because of its extraordinary physicochemical properties. Nanocellulose is extracted from cellulose whose hierarchical organization renders different types of nanomaterials (see Fig 1), one of the most interesting are cellulose nanocrystals (CNC). This small crystal has a length ranging from 100 to 500 nm and is currently produced by chemical hydrolysis using sulfuric acid. This hazardous process leaves sulfuric groups on the surface, changing CNC properties. Therefore, novel production methods are needed to achieve sustainable bio-based technology for CNC production and to keep cellulose properties intact.

Figure 1. The hierarchical structure of cellulose fiber permits its degradation into nanoscale particles. Here, we show how endoglucanase with CBM can attach to the cellulose fiber placing the catalytic domain in the fiber surface and improving its activity. Enzymes degradation can produce nanocellulose with different sizes depending on the hydrolysis time and enzyme usage.

Figure 1. The hierarchical structure of cellulose fiber permits its degradation into nanoscale particles. Here, we show how endoglucanase with CBM can attach to the cellulose fiber placing the catalytic domain in the fiber surface and improving its activity. Enzymes degradation can produce nanocellulose with different sizes depending on the hydrolysis time and enzyme usage.

We thought in enzymatic hydrolysis as one logical alternative to chemicals, but yields are low in biomass treatment. Besides, we notice that CNC obtention had never been performed using a single enzyme treatment; only strategies with cellulosic microbial cultures or a combination of enzymatic and other methods had been published. Our take to solve this problem was to use enzymes reconstructed by Ancestral Sequence Reconstruction (ASR). This technique is commonly used in molecular evolution studies but has an extraordinary potential in industrial applications. Several reports support that ancestral enzymes are more thermostable, promiscuous, and have higher catalytic activity than their modern counterparts. In our lab, we had successfully reconstructed several proteins as thioredoxin and titin. Besides, in recent work, we reconstructed an ancestral endoglucanase (ANC EG) from 2.8 billion-year ago that has superior performance in comparison with modern EGs. We thought that this could be handy for CNC production, and its catalytic activity was more improved by adding a carbohydrate-binding module (CBM) to the catalytic domain. In this work, we show how ancestral endoglucanase renders CNC successfully and at higher yields than modern EGs from bacteria and fungi. This enzymatically produced CNC (EnCNC) is chemically pure and displays higher thermal stability, crystallinity, and mechanical strength than CNC produced with the typical sulfuric acid hydrolysis (AcCNC).

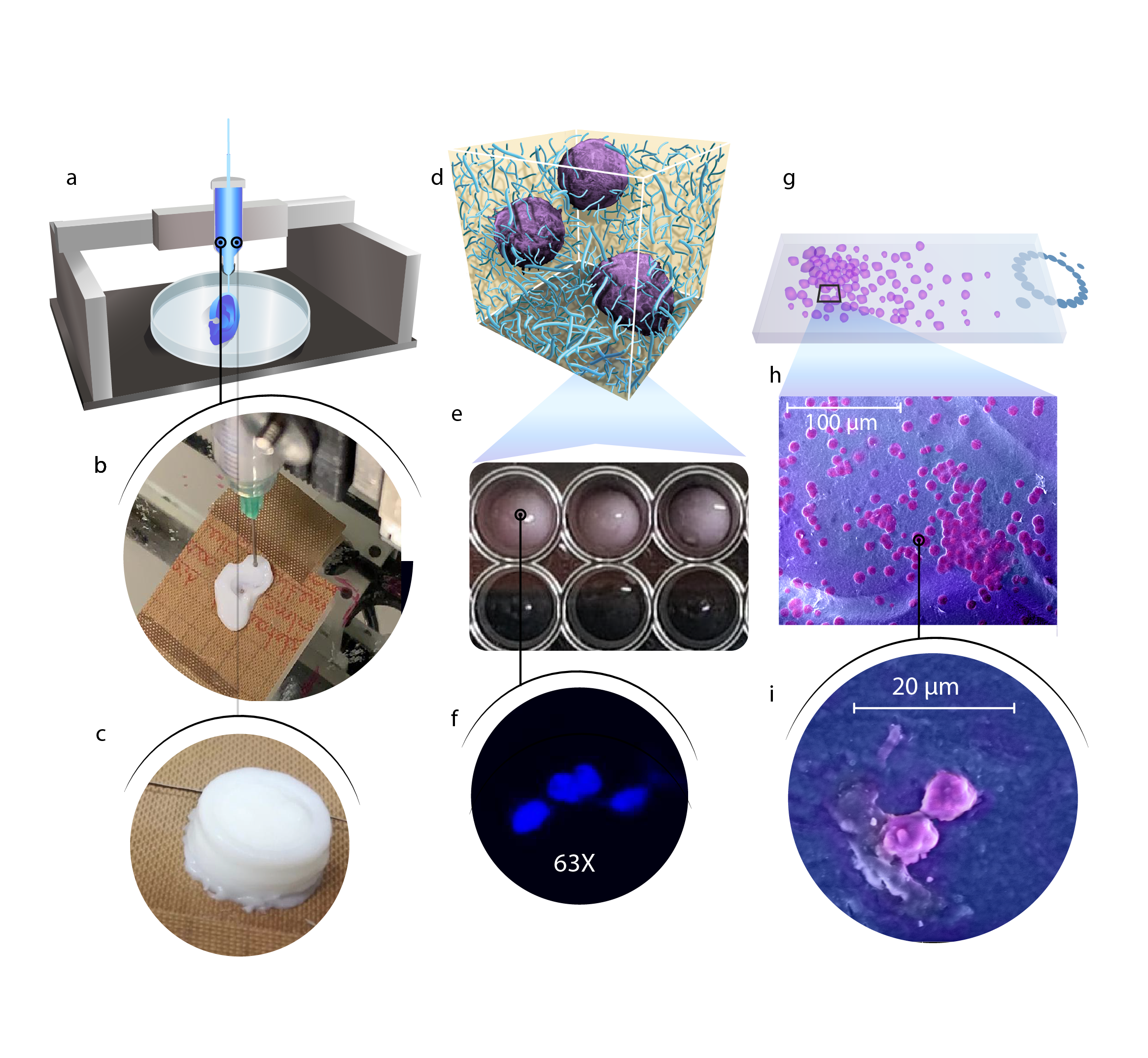

An essential part of this work was to study the possible applications of this CNC because of its unique properties where AcCNC failed. We show that EnCNC could be used in 2D and 3D culture and can be printed (see Figure 2). We observed how cells could thrive in this material and could be the base for future cell scaffold. Also, EnCNC mixes with graphene were used to fabricated different hybrid conductive materials. We mix EnCNC with reduced graphene oxide to fabricated strong conductive nanopapers, and also, we placed a graphene monolayer over EnCNC film to created transparent and conductive materials. In summary, given the biocompatibility of this EnCNC and graphene, we envision the use of these mixes to fabricated conductive printed inks for cells that respond to electrical stimulus or new biosensors.

Fig. 2 Cell proliferation on EnCNC 2D and 3D cultures. a Schematic representation of 3D printer using EnCNC suspension as ink. b, c Image of a human ear-like piece and scaffold printed with 10 wt% EnCNC suspension. d Representation of cells embedded on EnCNC matrix. e Portion of a 24-well plate containing a 3D-printed scaffold. f Confocal microscopy image HEK293T-stained nuclei with DAPI. g Schematic representation of 2D EnCNC for 2D cell culture. h, i SEM images of HEK293T living over EnCNC film after 3 days of culture.

For more details of our work, please check out the paper published in Communications materials: “High-performance crystalline nanocellulose using an ancestral endoglucanase” at the link: https://www.nature.com/articles/s43246-020-00055-5

Follow the Topic

-

Communications Materials

A selective open access journal from Nature Portfolio publishing high-quality research, reviews and commentary in all areas of materials science.

Related Collections

With Collections, you can get published faster and increase your visibility.

Advanced characterizations of high-entropy materials

Publishing Model: Open Access

Deadline: Mar 31, 2026

Multifunctional hydrogels

Publishing Model: Open Access

Deadline: Feb 28, 2026

Please sign in or register for FREE

If you are a registered user on Research Communities by Springer Nature, please sign in