Innovative Hydrogel Adhesives for Seamless Integration of Soft Electronic Devices

Published in Electrical & Electronic Engineering, Materials, and Physics

Soft electronics have received significant attention due to their potential to revolutionize human-machine interaction by bridging the mechanical disparity between traditional rigid electronics and soft tissues. Soft electronic devices now require incorporating diverse components such as elastomers, hydrogels, and rigid silicon-based chips. These soft and rigid components should be seamlessly integrated and robustly combined for the reliable operation of the devices under dynamic movement conditions. However, integrating these diverse components into a single device has been challenging due to their differing mechanical properties, surface characteristics, and moisture content.

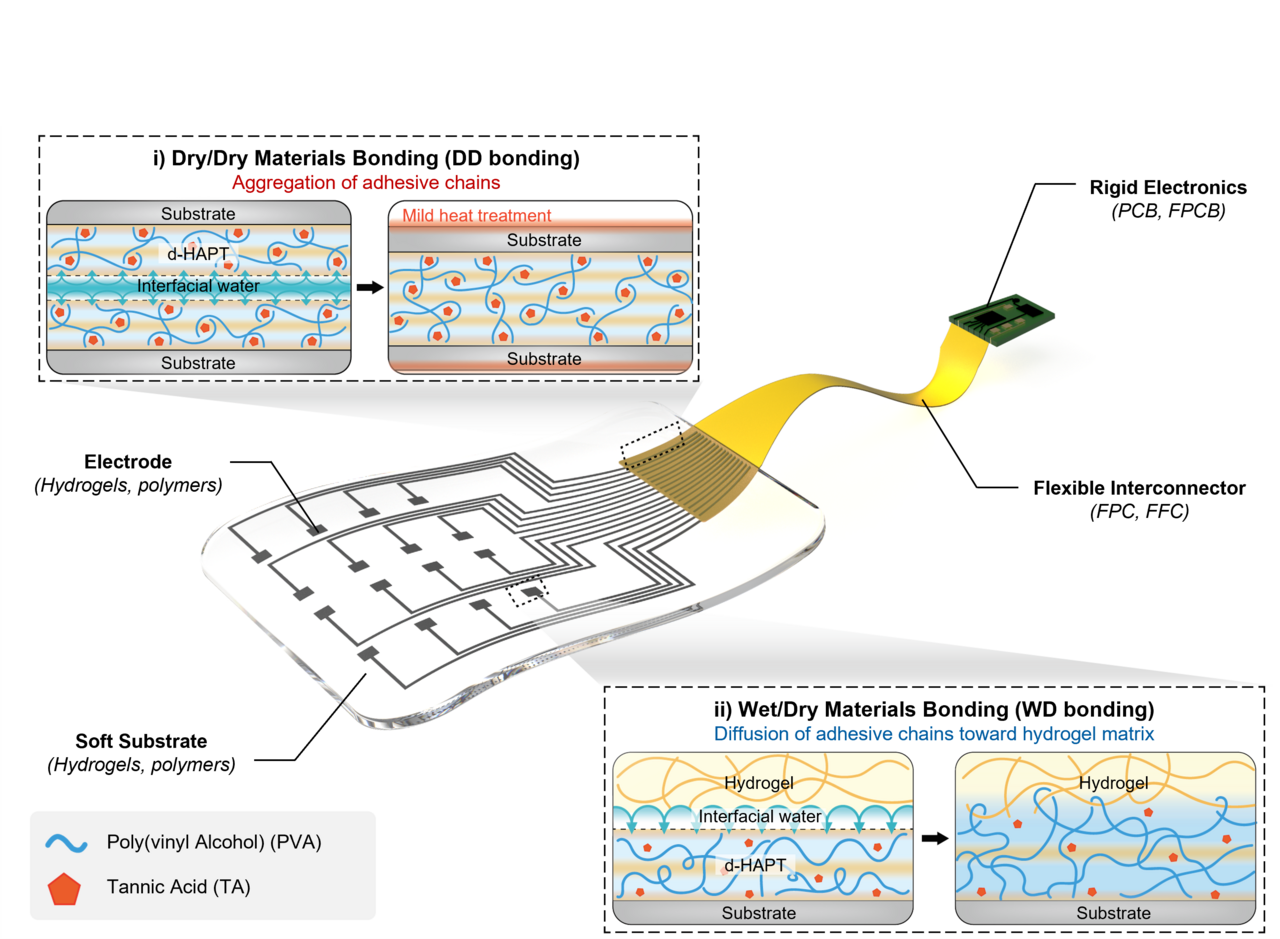

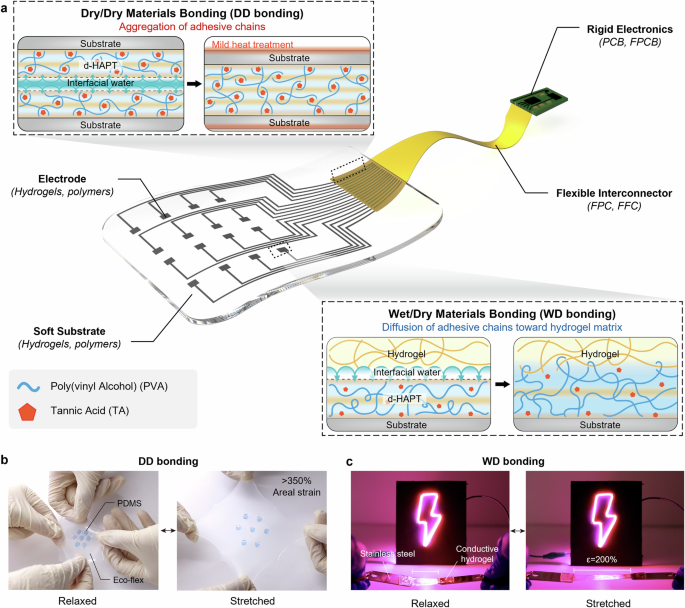

Recently, a team led by Prof. Seo at the Biological Interface and Sensor System lab, at Yonsei University developed a versatile adhesive technology applicable to the integration of flexible electronic devices (Fig. 1). This adhesive is a dried-hydrogel adhesive made of multilayered poly(vinyl alcohol) and tannic acid (d-HAPT). d-HAPT demonstrates excellent adhesive performance between various heterogeneous materials through two methods: dry/dry materials bonding (DD bonding) and wet/dry materials bonding (WD bonding). The key mechanism for these methods is moisture-derived chain entanglement, which occurs when the d-HAPT absorbs moisture.

.png)

Figure 1. Schematic of a soft electronic device consists of a soft substrate, electrode, rigid electronics, and flexible interconnector which were integrated using d-HAPT via DD bonding and WD bonding.

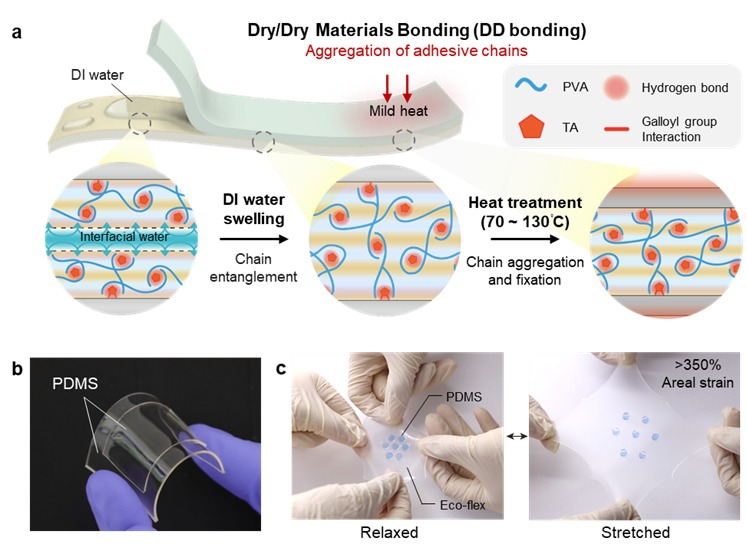

DD bonding enables adhesion among dry materials such as elastomers, plastics, rigid electronics, metals, etc. As shown in Fig. 2a, d-HAPT absorbs interfacial water and swells, thereby increasing chain mobility. The enhanced chain mobility leads to the entanglement of chains across the dry substrates. Additionally, as polymer and water molecules compete for hydrogen bonding sites, plasticization occurs which leads to interdiffusion between PVA and TA. Then the adhesive chains are aggregated and fixated by subsequent mild heat treatment applied to evaporate the residual water from d-HAPT. The bonded sample was highly transparent (Fig. 2b), and the strong adhesion was maintained even when subjected to repeated areal strain of up to 350% (Fig. 2c).

Figure 2. Dry/dry materials bonding. (a) Schematic illustration of two dry substrates adhered through DD bonding. (b) Optical image of PDMS substrates integrated using d-HAPT. (c) Stretching of round-shaped PDMS discs attached to Eco-flex substrate via DD bonding.

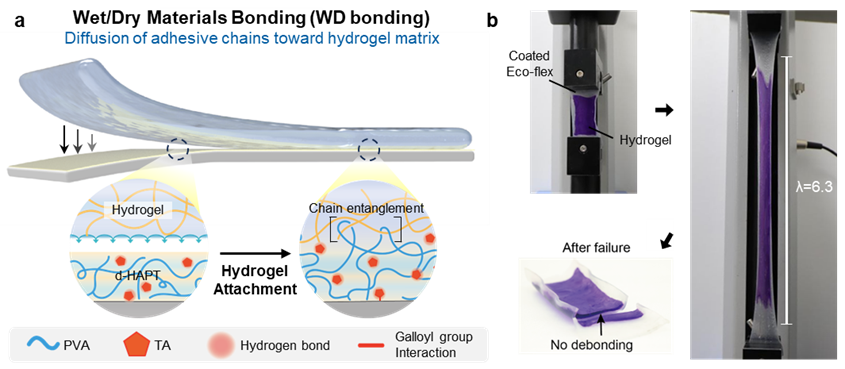

WD bonding allows the attachment of hydrogels to dry substrates. To attach the hydrogels, they are simply placed onto the adhesive-coated substrates. As shown in Fig. 3(a), when the hydrogel is attached to the d-HAPT-coated substrates, the d-HAPT absorbs the water at the interface with the hydrogel matrix. The absorbed moisture leads to the diffusion of polymer chains of the adhesive into the hydrogel matrix, thereby entangling the hydrogel network. The attached hydrogel on the d-HAPT-coated Eco-flex substrate endured extensive tensile stress without debonding, with strain up to 630%.

Figure 3. Wet/dry materials bonding. (a) Schematic illustration of WD bonding between the hydrogel and a dry substrate. (b) Stretching of hydrogel attached to d-HAPT coated eco-flex.

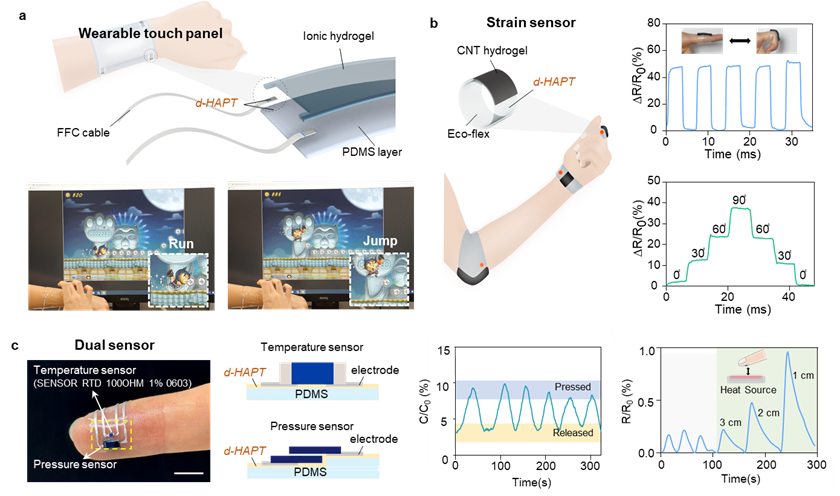

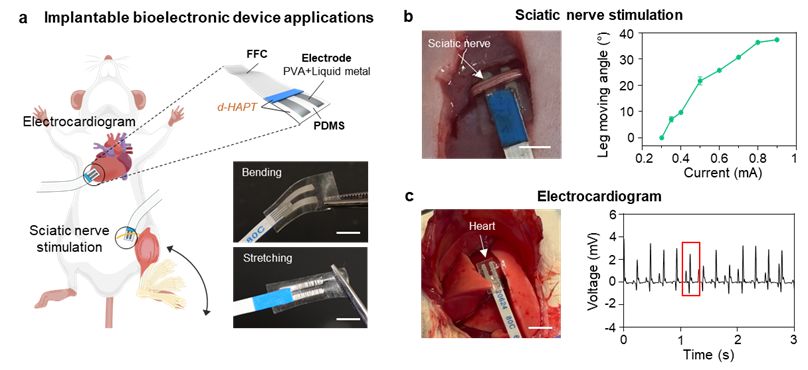

As the biocompatibility and electrical connect ability of d-HAPT, various wearable and implantable devices could be fabricated. As displayed in Fig. 4 and 5, the components of a wearable touch panel, strain sensors, a dual sensor, and implantable devices were integrated using d-HAPT. These devices seamlessly connect to the human body and perform stably in a bending or stretching environment. These findings demonstrate stable integration of rigid sensors to soft materials via d-HAPT showing great potential to be used in wearable and implantable biosensors.

Figure 4. Wearable device applications of d-HAPT (a) A wearable touch panel. (b) Strain sensors. (c) A dual sensor.

Figure 5. Implantable device applications of d-HAPT. (a) Schematic of implantable bioelectronic device application and optical images of bending and stretching of the implantable device.

This adhesive technology is not only applicable to flexible electronic devices but is also expected to be integrated into 2.5D and 3D semiconductor packaging technologies for high-performance computing processors requiring high integration in the future. Therefore, it is anticipated to introduce a new paradigm in various electronic device packaging fields.

For more details, please read the original version of the manuscript:

Yejin Jo, Yurim Lee, Jeong Hyun Heo, Yeonzu Son, Tae Young Kim, Kijun Park, Soye Kim, Seo Jung Kim, Yoonhee Jin, Seongjun Park, Jungmok Seo*, Universal hydrogel adhesives with robust chain entanglement for bridging soft electronic materials. npj Flexible Electronics, 8 39 (2024).

Link:

https://www.nature.com/articles/s41528-024-00327-x

Follow the Topic

-

npj Flexible Electronics

This journal publishes high-quality papers related to flexible electronic systems, including plastic electronics and emerging materials, new device design and fabrication technologies, and applications.

Related Collections

With Collections, you can get published faster and increase your visibility.

Neuromorphic Circuits and Bio-inspired Systems

Publishing Model: Open Access

Deadline: Mar 31, 2026

Living and Biomaterials based Sustainable Flexible Electronics

Publishing Model: Open Access

Deadline: Aug 24, 2026

Please sign in or register for FREE

If you are a registered user on Research Communities by Springer Nature, please sign in