It’s time for natively flexible processors

Published in Electrical & Electronic Engineering

The story behind our paper A hardwired machine learning processing engine fabricated with sub-micron metal-oxide thin-film transistors on a flexible substrate started with a question of how to make billions of everyday things smart. For example; food packaging, deodorants, detergents, bandages, – the list goes on. The simplest response to this question was to attach some cheap electronics (~$5) to them to make them smarter. But, the definition of low-cost electronics is relative: adding $5 to a $200 handbag will not make much of a difference in the selling price, but adding the same electronics to a 50 cent milk bottle is a showstopper.

In spite of the great success of conventional electronics, the high costs of Si-based semiconductor fabrication makes it impossible to manufacture them at the cost point necessary to make ultra cost-sensitive things smarter. This is where flexible electronics comes to the rescue. Unlike conventional electronics, flexible electronics are inherently thin, and conformable. Most importantly, the manufacturing system has also been designed to enable ultra low-cost production with rapid turnaround times. In this way, it is possible to design the most optimised processor for the job, rather than a general processor.

From a technology point of view, to make a “dumb” thing smarter, three modalities are essential: sensing, processing and communicating. Printed sensors have been around for a long time for communication purposes, and flexible NFC antennas and circuitry are being developed both in academia and industry. What is missing is a flexible processor.

Arm and PragmatIC embarked on the fully custom design, implementation and fabrication of a processor with thin-film transistors (TFTs) on a flexible substrate. We define and use the term “Natively Flexible Processing Engine (NFPE)” to describe this processor throughout the Article.

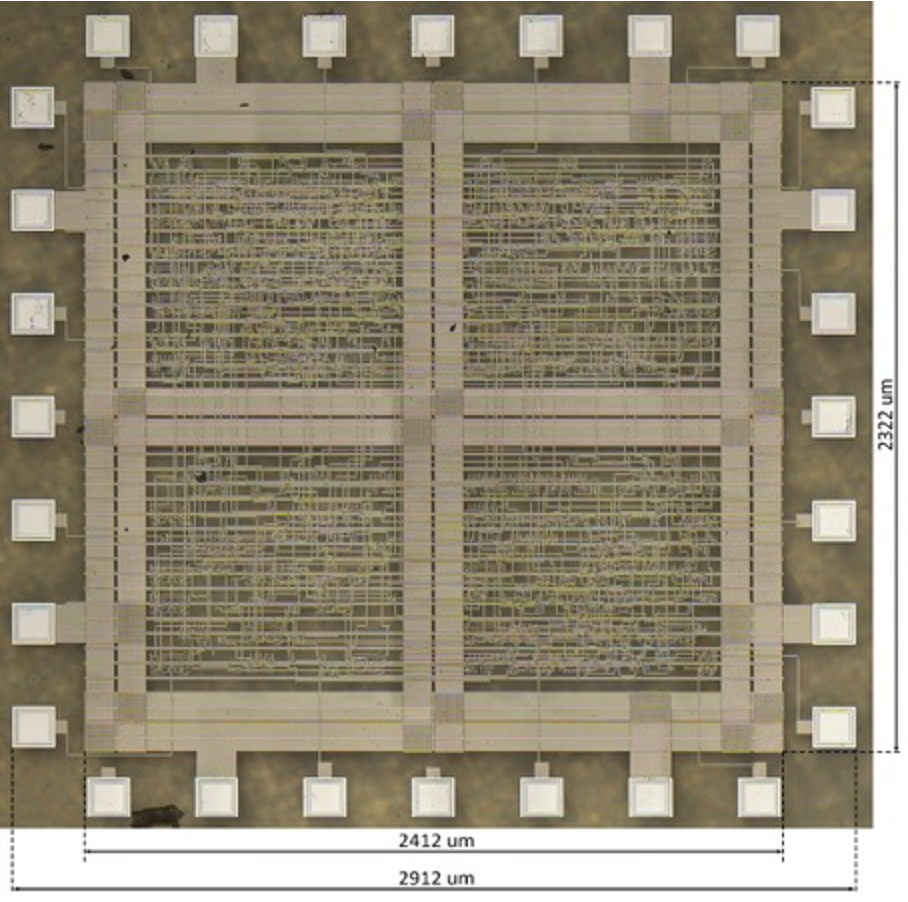

In the Article, we demonstrate our NFPE can be directly attached to an e-nose sensor to process the data and make decisions based on it. It is a machine learning (ML) processing engine that reads the e-nose sensor data for odour recognition application, and recognises the odour intensity level. The ML NFPE is the implementation of a resource-efficient ML algorithm that we also developed; ‘Univariate Bayes feature voting classifier’. We fabricated and validated the ML NFPE as a flexible IC using PragmatIC’s 0.8µm process with n-type metal-oxide TFTs as shown in Fig. 1. The ML NFPE is the most complex digital circuit fabricated with metal-oxide TFTs to date.

Fig. 2 Various ML NFPEs can be fabricated on polyimide substrate for various applications each of which have their own requirements and learned parameters.

Although the ML NFPE was developed for a specific odour-based application, the methodology is generic enough to be adapted to other odour-based applications (e.g. food packaging, wound dressing, room air quality detection etc.) to develop a new ML NFPE specific to the application under consideration (see Fig. 2).

More details about our journey can be found in the Article:

Follow the Topic

-

Nature Electronics

This journal publishes both fundamental and applied research across all areas of electronics, from the study of novel phenomena and devices, to the design, construction and wider application of electronic circuits.

Please sign in or register for FREE

If you are a registered user on Research Communities by Springer Nature, please sign in

Great work!

Thank you!

very interesting. i wonder if this method can produce more advanced microprocessors for more complex tasks?

It can produce more advance microprocessors and we are working on it too. Please send me an email if you would like to know more about it.