Machine-Learning aided design of novel radiation detection materials

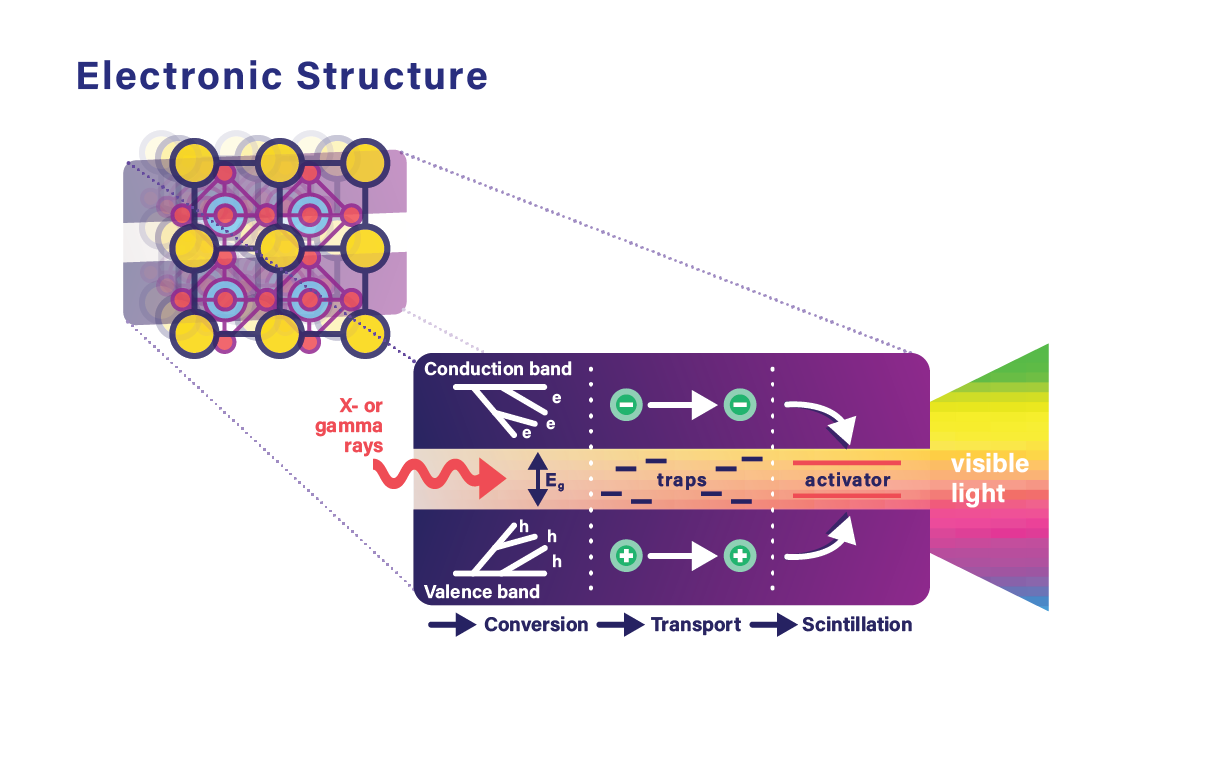

Scintillators are materials that emit light when exposed to high-energy radiation such as X-rays and γ-rays (Figure 1). Each photon of radiation that interacts with the scintillator material results in a distinct flash of light, meaning that in addition to being highly sensitive, scintillation detectors are able to capture spectroscopic profiles for the radioactive materials of interest.

Historically, new detector materials have been predominantly developed through resource intensive trial-and-error techniques, typically requiring about 10 years from discovery to deployment. While this approach has had success, it leaves a vast space of potentially revolutionary materials unexplored. Scintillators have diverse applications - ranging from medical imaging (for instance, they are used in CT scanners), to X-ray security, to space applications.

However, each application has different requirements - some may require high resolution while for another application the light yield may be paramount. While scintillator development has seen exponential advances over the years, there are still a limited number of commercially available scintillators today. Hence most applications use off-the-shelf scintillators and make do with whatever is available rather than using a custom designed, and thus more optimized, scintillator tailored to the application.

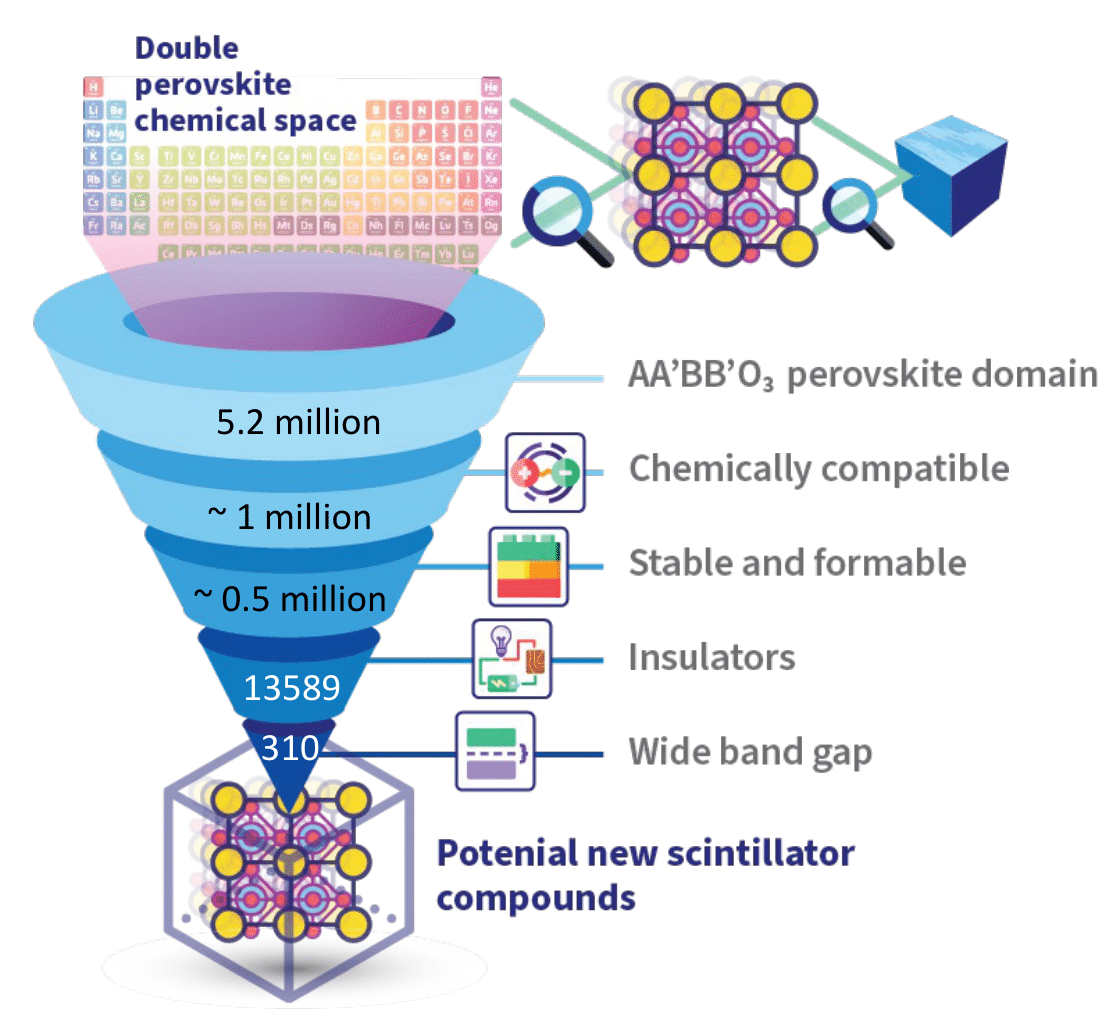

To design custom scintillators, we need to search the space of possible materials and identify chemically compatible compositions and then isolate candidates that should i) be thermodynamically stable, ii) experimentally formable, iii) have a suitable band gap, iv) havefavorable activator states to exhibit scintillation, and finally v) possess the requisite target property. In this work, we focus on steps (i)- (iii).

As a first step, we focus on the class of double oxide perovskites and implement a hierarchical screening process (Figure 2) in which cross-validated and predictive machine learning models for band gap classification and regression, trained using exhaustive datasets that span 68 elements of the periodic table, are applied sequentially. That is, we first classify compounds based on whether they have a small or large band gap and then, for those with suitably large band gaps, we predict the actual value of the band gap. This provides a more robust screening than trying to predict the band gap for both metallic and insulating compounds. We apply these models to investigate a previously identified [1] exhaustive chemical space of formable and stable cubic single and double oxide perovskites, ultimately identifying 310 candidates which are predicted to be experimentally formable, thermodynamically stable, are insulators, and possess a wide band gap. This set of materials may be further investigated using models to predict high-fidelity band gaps [2], defect states [3], and targeted scintillator properties [4].

Our multi-step hierarchical screening approach may be generalized to investigate other classes of materials in addition to the oxide perovskites examined here. The efficiency of these models provides further impetus to the application of physics-based ML models to the discovery of novel functional materials.

For more details, please refer to our paper at: https://www.nature.com/articles/s43246-023-00373-4

LA-UR-23-33741

References:

[1] Talapatra, A., Uberuaga, B. P., Stanek, C. R., & Pilania, G. (2021). A machine learning approach for the prediction of formability and thermodynamic stability of single and double perovskite oxides. Chemistry of Materials, 33(3), 845-858.

[2] Pilania, G., Gubernatis, J. E., & Lookman, T. (2017). Multi-fidelity machine learning models for accurate bandgap predictions of solids. Computational Materials Science, 129, 156-163.

[3] Pilania, G., McClellan, K. J., Stanek, C. R., & Uberuaga, B. P. (2018). Physics-informed machine learning for inorganic scintillator discovery. The Journal of chemical physics, 148(24).

[4] Pilania, G., Liu, X. Y., & Wang, Z. (2019). Data-enabled structure–property mappings for lanthanide-activated inorganic scintillators. Journal of Materials Science, 54, 8361-8380.

Follow the Topic

-

Communications Materials

A selective open access journal from Nature Portfolio publishing high-quality research, reviews and commentary in all areas of materials science.

Related Collections

With Collections, you can get published faster and increase your visibility.

Advanced characterizations of high-entropy materials

Publishing Model: Open Access

Deadline: Mar 31, 2026

Multifunctional hydrogels

Publishing Model: Open Access

Deadline: Feb 28, 2026

Please sign in or register for FREE

If you are a registered user on Research Communities by Springer Nature, please sign in